Lifting type plate feeding device

A supply device and lifting technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems that the supply accuracy of the backboard cannot meet the production requirements and the work efficiency is low, and improve the supply efficiency of the board. The effect of improving the accuracy of sheet supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

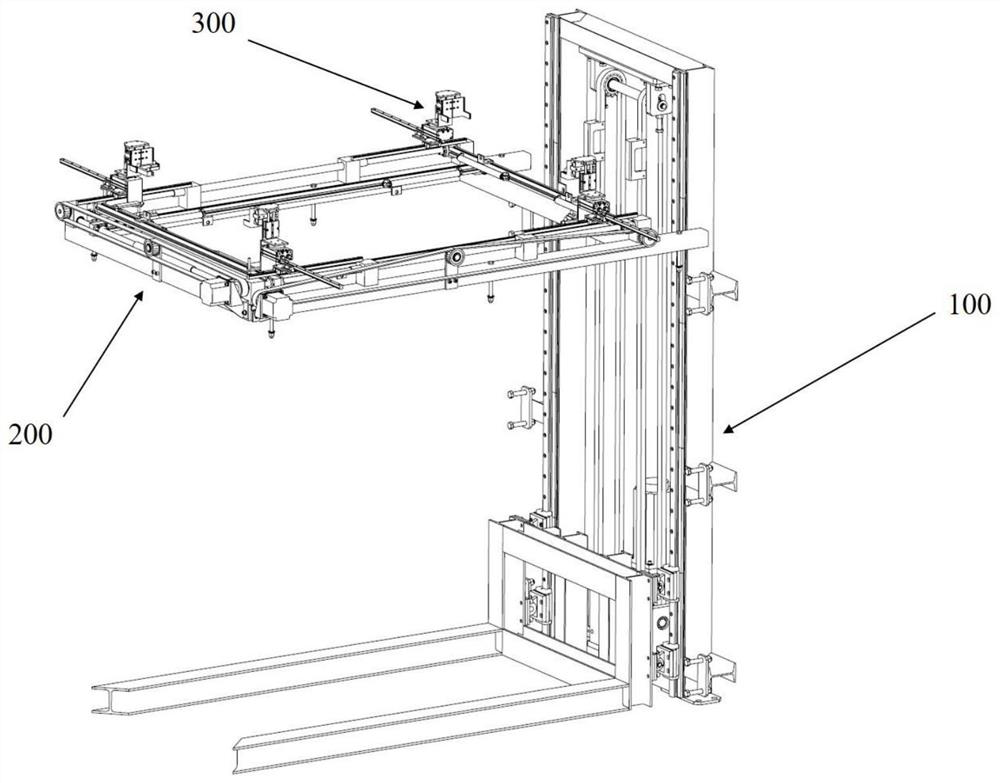

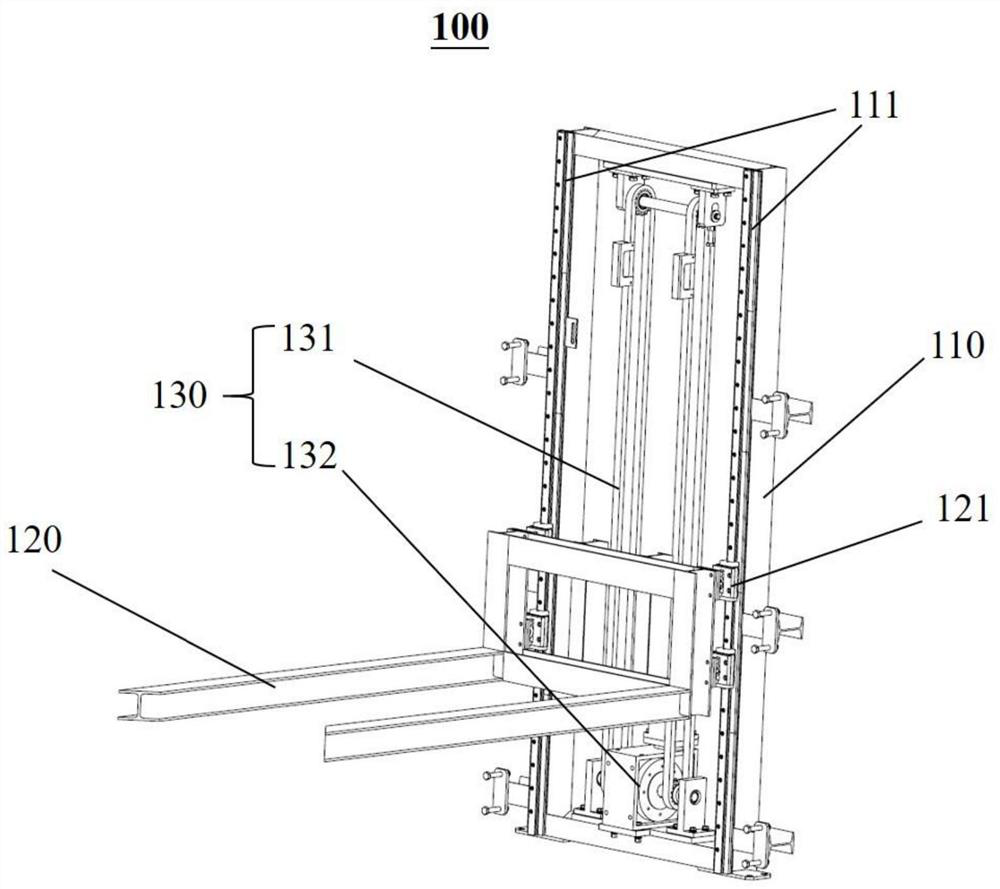

[0032] Hereinafter, preferred embodiments of the present invention are described in detail with reference to the accompanying drawings so that those of ordinary skill in the art to which the present invention pertains can easily understand the present invention.

[0033] This article only describes the parts necessary to understand the technical content of the present invention, and the description of the remaining parts will be omitted to avoid confusion of the gist of the present invention, which should be noted. Also, in this process, for the sake of clarity and convenience of description, the thickness of lines shown in the drawings or the size of constituent elements may be exaggerated in illustration.

[0034] Herein, the terms used are used to describe the embodiments and are not intended to limit and / or define the present invention. When it is expressed that a certain constituent element is "connected", "coupled" or "engaged" with another constituent element, this incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com