Cementing automatic feeding device

A technology of automatic feeding and equipment, applied in transportation and packaging, conveyor objects, roller tables, etc., can solve the problem that robots cannot automatically grab books, etc., to reduce manual operation time and labor force, high precision material supply, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

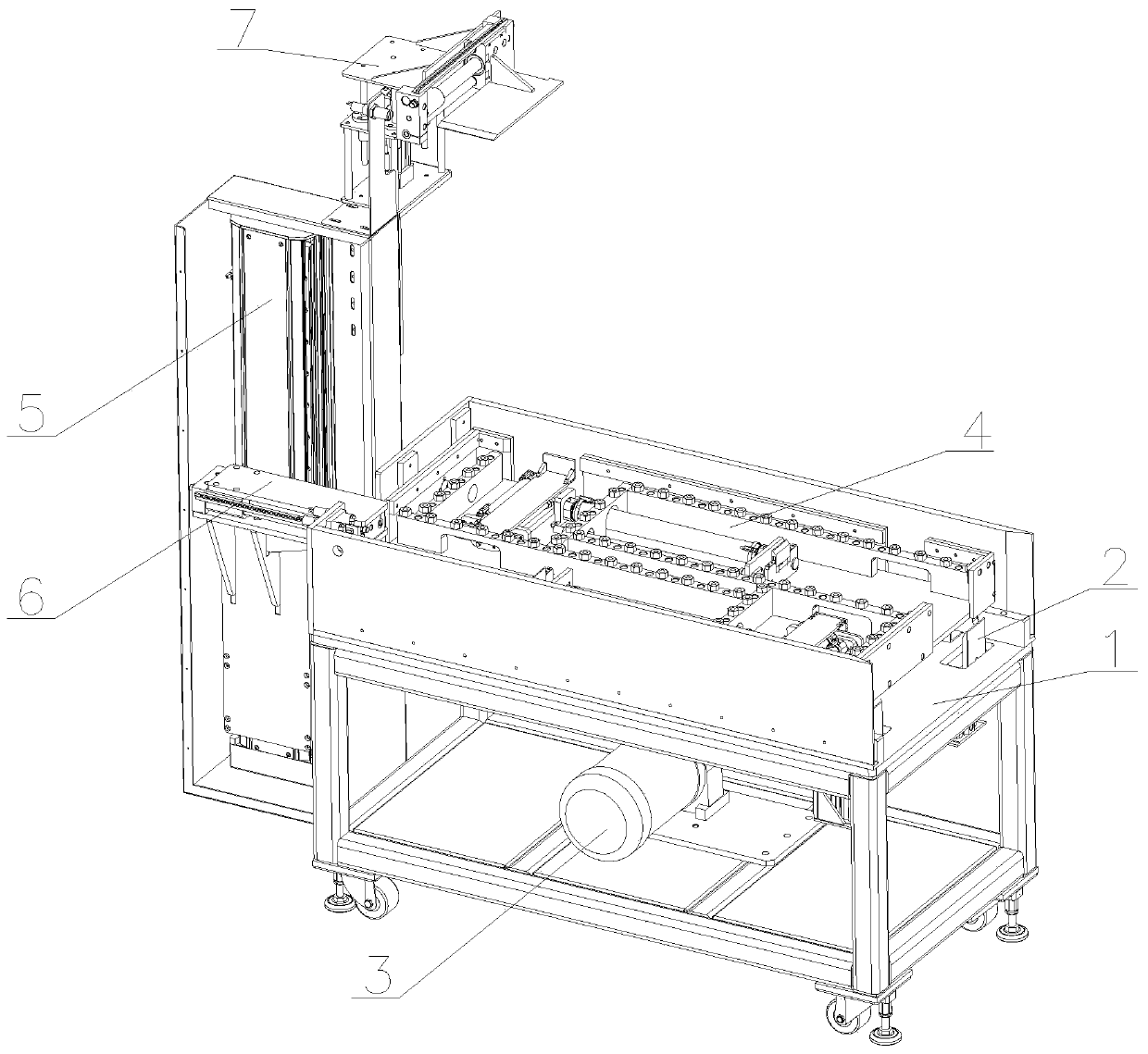

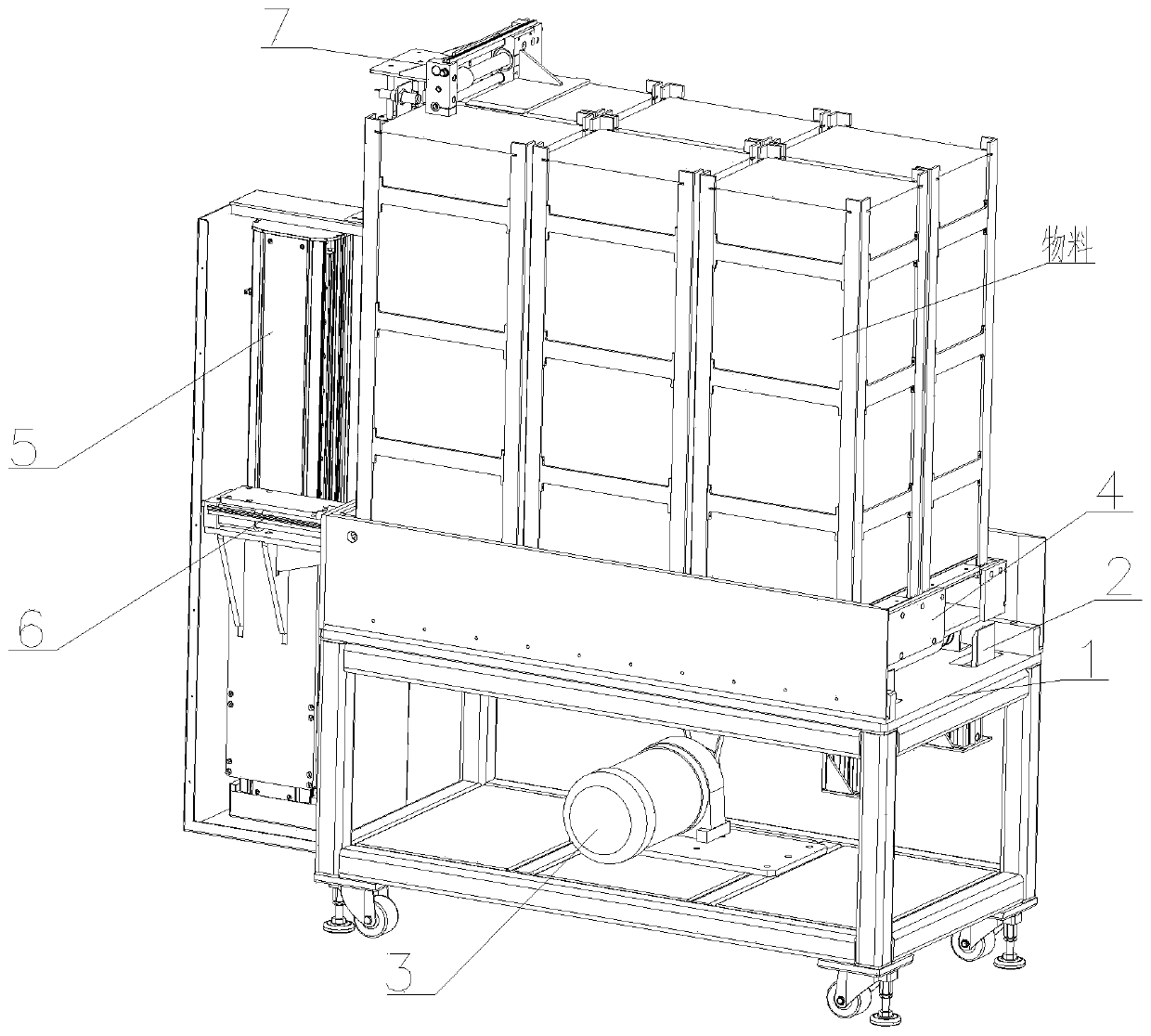

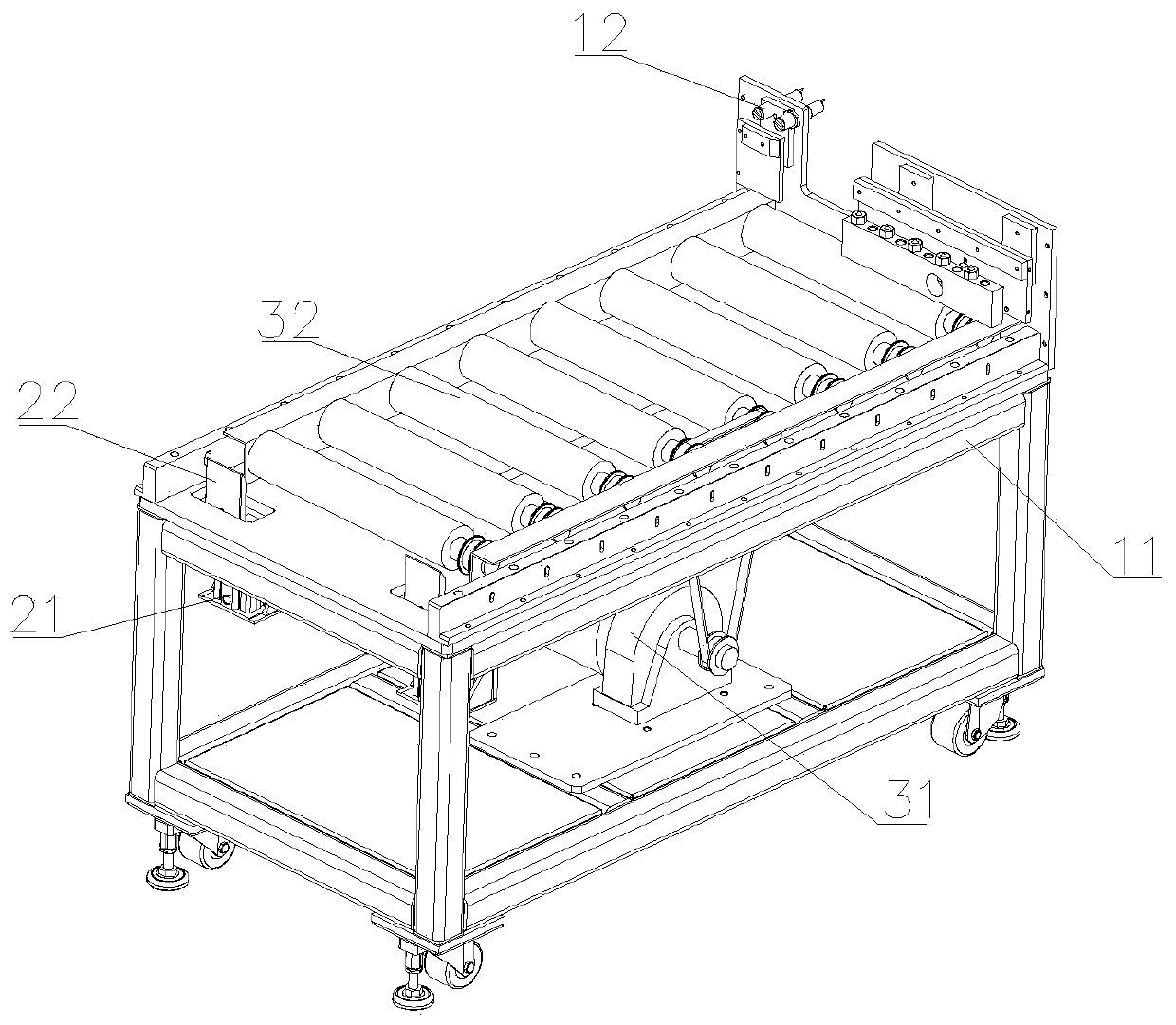

[0026] refer to figure 1 and figure 2 , the present invention is an automatic loading device for plastic packaging, comprising a material transfer table 1, a tray limit mechanism 2, a tray transmission power mechanism 3, a tray 4, a material supply mechanism 5, a material lifting mechanism 6, and a material quantitative lifting mechanism 7 and a switch control box, the material transfer platform 1 is provided with a pallet 4, the staff puts the stacked materials on the pallet, and then puts the pallet on the pallet 4, the electric and pneumatic components on the pallet 4 are connected to each other through the joint The switch control box is connected, and the material conveying platform 1 at one end of the tray 4 is provided with a material supply mechanism 5, and the material conveying platform 1 at the other end is provided with a tray limiting mechanism 2, and the tray limiting mechanism 2 is used to limit the sliding of the tray 4 out of the material. Conveying platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com