A winch for ship traction and hoisting

A hoist and ship technology, applied in the field of machinery, to achieve the effects of lowering temperature, reducing maintenance costs, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

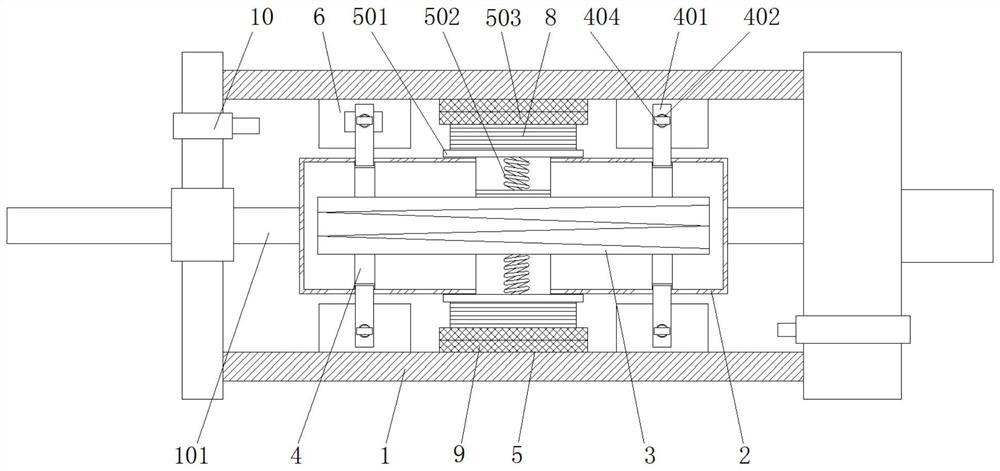

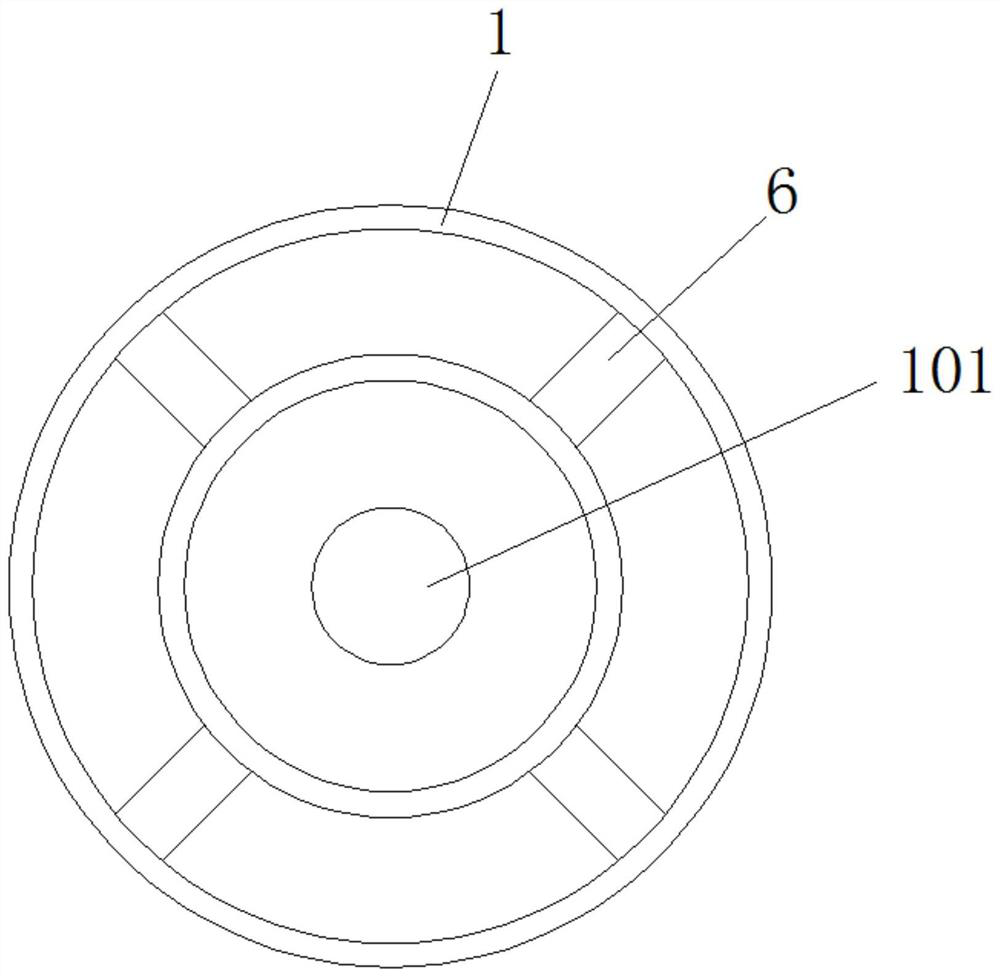

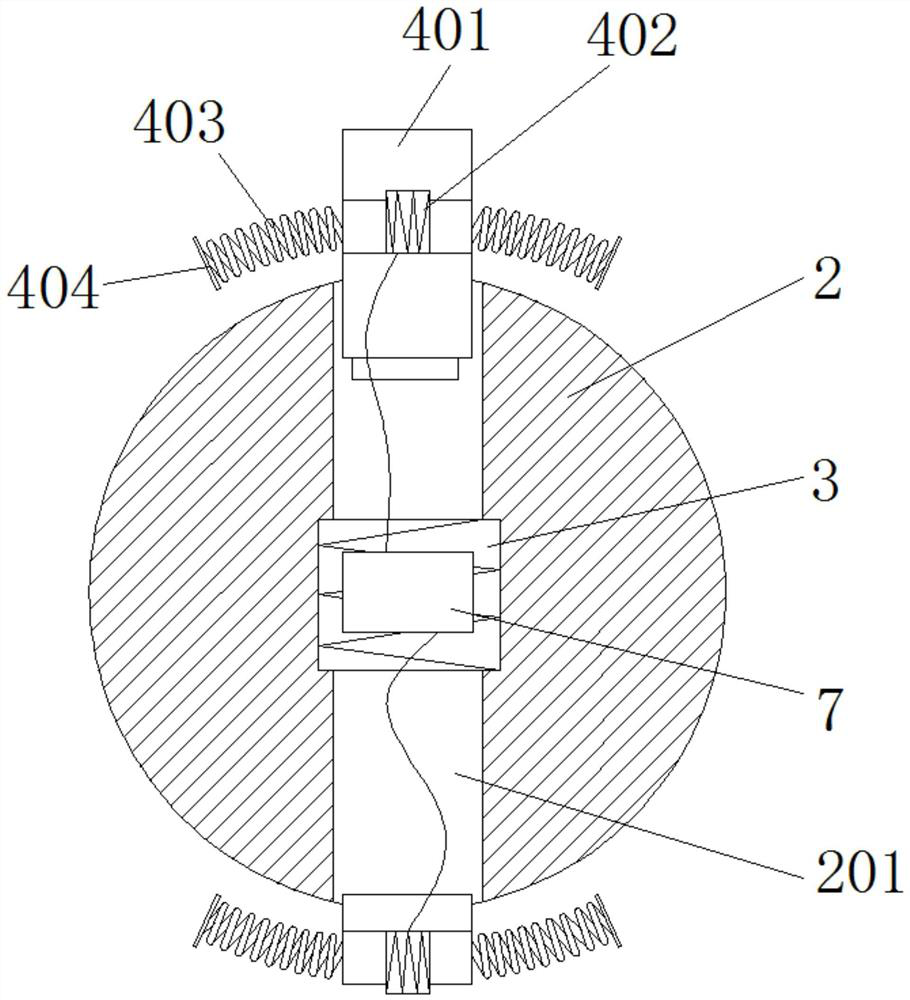

[0022] See Figure 1-4 A ship is induced by a reuse of the hoisting machine, including the reel 1, one end of the reel 1 rotates to be connected to the fixing rod 101, the fixing rod 101 is connected to the fixed bracket, and the other end of the reel 1 is connected to the spinning axis, thereby driving the roll The cartridge 1 rotates, the fixing lever 101 extends into the inner cavity of the reel 1 and fixed to the inner cylinder 2, and the other end of the inner cylinder 2 is rotated on the inner wall of the reel 1, in wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com