A converter tapping hole, converter and converter masonry, and steel tapping method

A technology for tapping hole and converter furnace body is applied in the field of iron and steel metallurgy, which can solve the problems of high production process and refractory quality requirements, increased use cost, generally small, and medium-sized converters are not suitable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

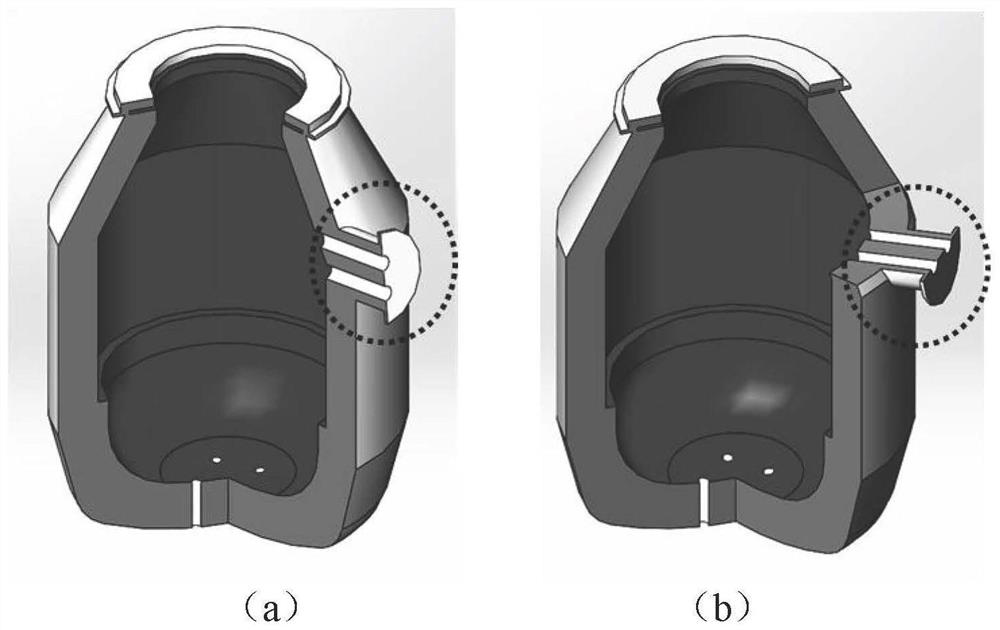

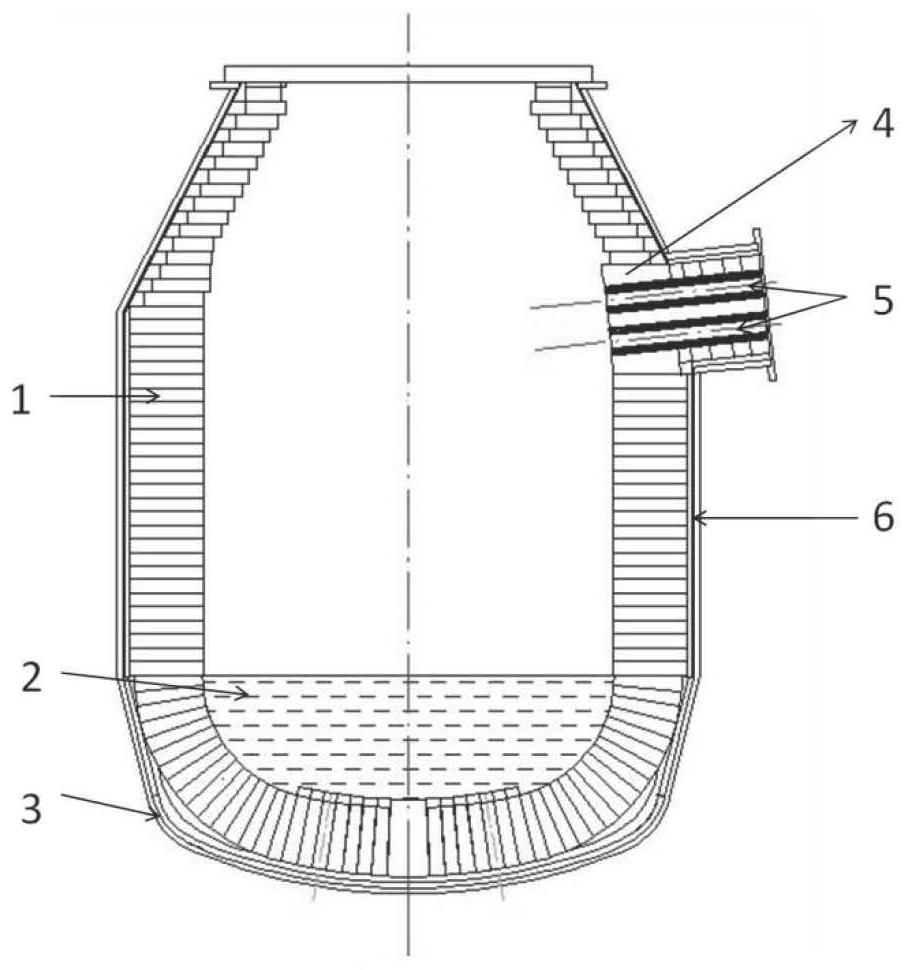

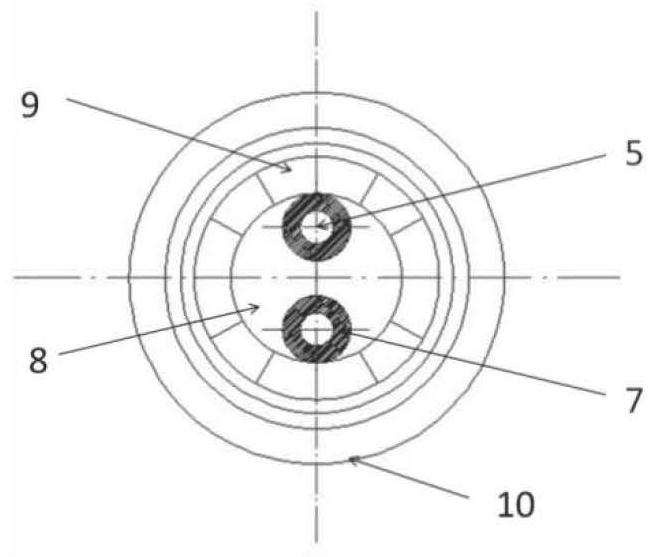

[0062] This embodiment provides a converter and a converter tapping method. Take the operation of a converter for smelting and processing a certain 300t molten steel as an example. Brick 9, tapping hole jacket brick 8, tapping hole inner seat brick 4 and tapping hole shell 10, such as figure 1 As shown in (a), the number of molten steel channels 5 is two, and the two molten steel channels 5 are arranged side by side and parallel in the same axial section of the converter (that is, in a vertical form), and the slag blocking method is a sliding plate slag blocking method.

[0063] Specifically, according to the size of the converter, the annular bricks of the tapping hole are manufactured and processed, using 98.5% high-purity fused magnesia and 98% high-purity graphite, and mechanical compaction is used during production. The chemical composition of the tapping hole annular bricks The mass percentages are: MgO 85.1%, graphite 12.2%, carbon black 1.6%, Ce-Fe alloy 1.1%; the bulk...

Embodiment 2

[0071] This embodiment provides a converter and a converter tapping method. Taking the operation of a converter for smelting and processing a certain 120t molten steel as an example, the tapping hole includes a molten steel channel 5, a tapping hole ring brick 7, a tapping hole outer seat brick 9, and a tapping hole Overcoat brick 8, taphole inner seat brick 4 and taphole shell 10, wherein the quantity of molten steel channel 5 is two, as figure 1 As shown in (b), two molten steel channels 5 are arranged side by side and parallel in the same radial section of the converter (that is, in a horizontal form), and the slag blocking method is slag blocking ball.

[0072] Specifically, according to the size of the converter, the annular bricks of the tapping hole are manufactured and processed, using 98.5% high-purity fused magnesia and 98% high-purity graphite, and mechanical compaction is used during production. The chemical composition of the tapping hole annular bricks The mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com