A semi-active sma-piezoelectric composite gear friction damper

A friction damper and piezoelectric composite technology, which is applied in the direction of building types, buildings, building components, etc., can solve the problem that friction materials cannot be fully utilized, achieve good self-resetting effect, improve utilization rate, and have a significant effect of frictional energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

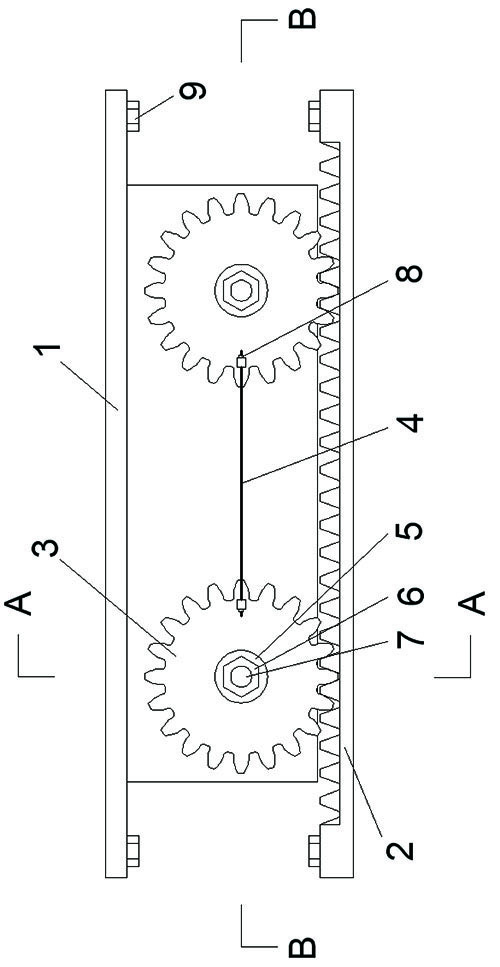

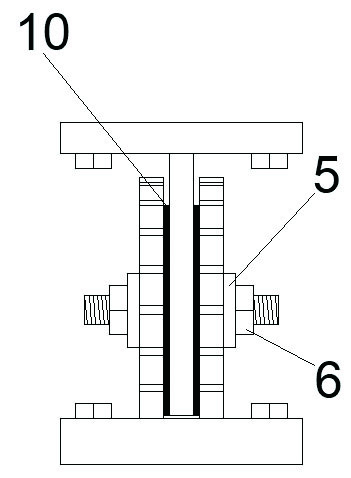

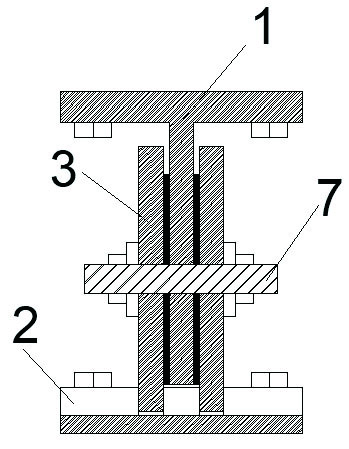

[0009] The present invention is a semi-active SMA-piezoelectric composite gear friction damper, including a T-shaped connector 1, an annular friction plate 10 and a gear 3 with a connecting hole installed on both sides of the T-shaped connector 1 through a screw 7, An annular piezoelectric ceramic driver 5 installed on the outside of the gear 3, a nut 6 that fixes each component and applies a pre-tightening force; the gear 3 is placed at the center of the lower connecting plate 2 with a rack, and meshed with the rack The screw 7 fixes the annular friction plate 10, the gear 3 with the connecting hole and the annular piezoelectric ceramic driver 5 on both sides of the T-shaped connector 1 in sequence, and reserves holes on the same side of the T-shaped connector 1 Arrange two groups symmetrically.

[0010] In the semi-active SMA-piezoelectric composite gear friction damper described above, the connecting hole of the gear 3 on the same side of the T-shaped connector 1 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com