Gas prediction model after coal mining

A forecasting model and gas technology, applied in the field of forecasting model and gas forecasting model after coal mining, can solve the problem of inaccurate analysis of gas emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

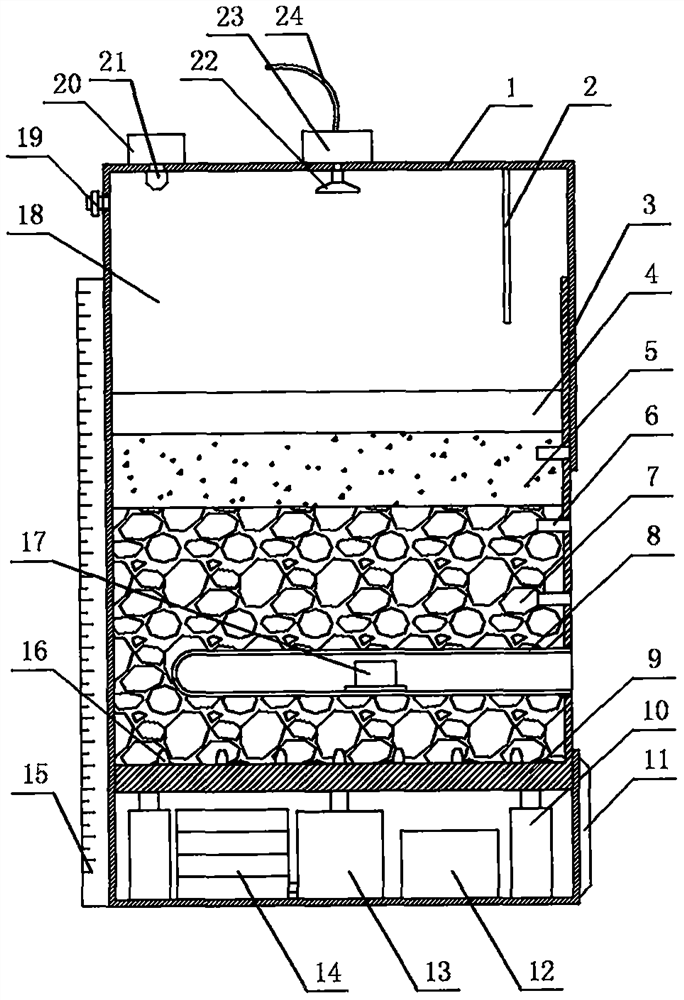

[0031] A gas prediction model after coal mining of the present invention is realized in the following way: a gas prediction model after coal mining of the present invention includes a main body box (1), a simulation system and a gas emission detector (17), and the simulation system is placed in the main body In the box (1), the gas emission detector (17) is placed in the simulation system. After the simulation system simulates the roadway scale, atmospheric pressure, mining depth, and gas concentration, the gas emission detector (17) will to test;

[0032] The main body box (1) is a rectangular transparent box structure, which is convenient to compare with the scale (15) to fill the soil layer and simulate the depth of the soil layer;

[0033] There is a through groove on the side of the main body box (1);

[0034] The simulation system includes an atmosphere simulation device, a roadway simulation device, a gas quantity simulation device and a control device, the roadway sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com