A molded case circuit breaker multi-touch finger moving contact and contact system

A moulded case circuit breaker and moving contact technology, applied in circuit breaker contacts, circuit breaker parts, overload protection circuit breakers, etc., can solve the problem of large contact spring design, difficult contact spring design, and contact resistance. It can increase the effective contact area, improve the short-term tolerance, and reduce the contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

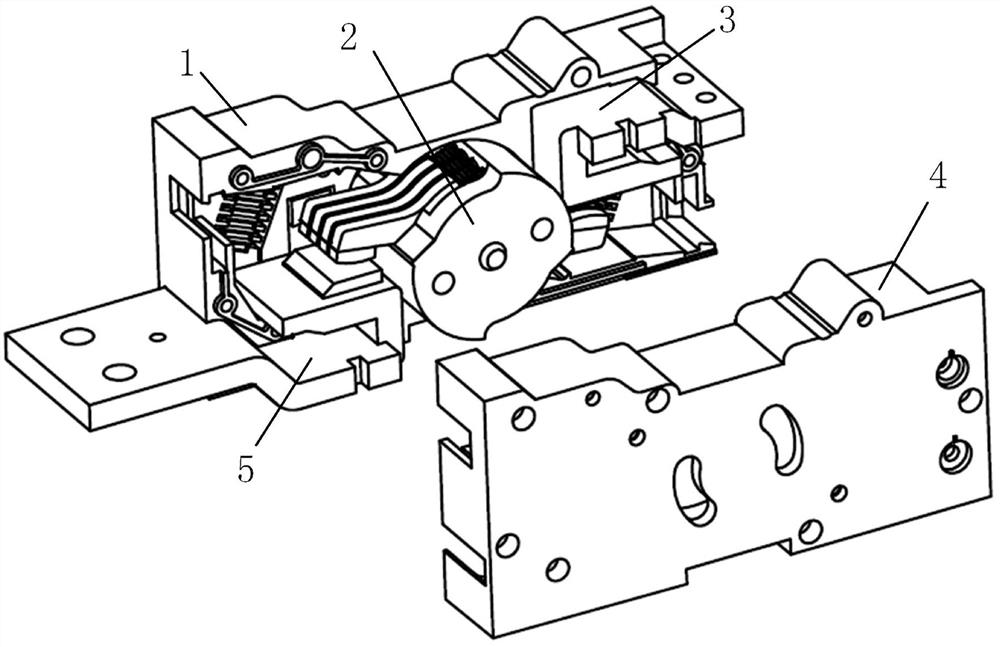

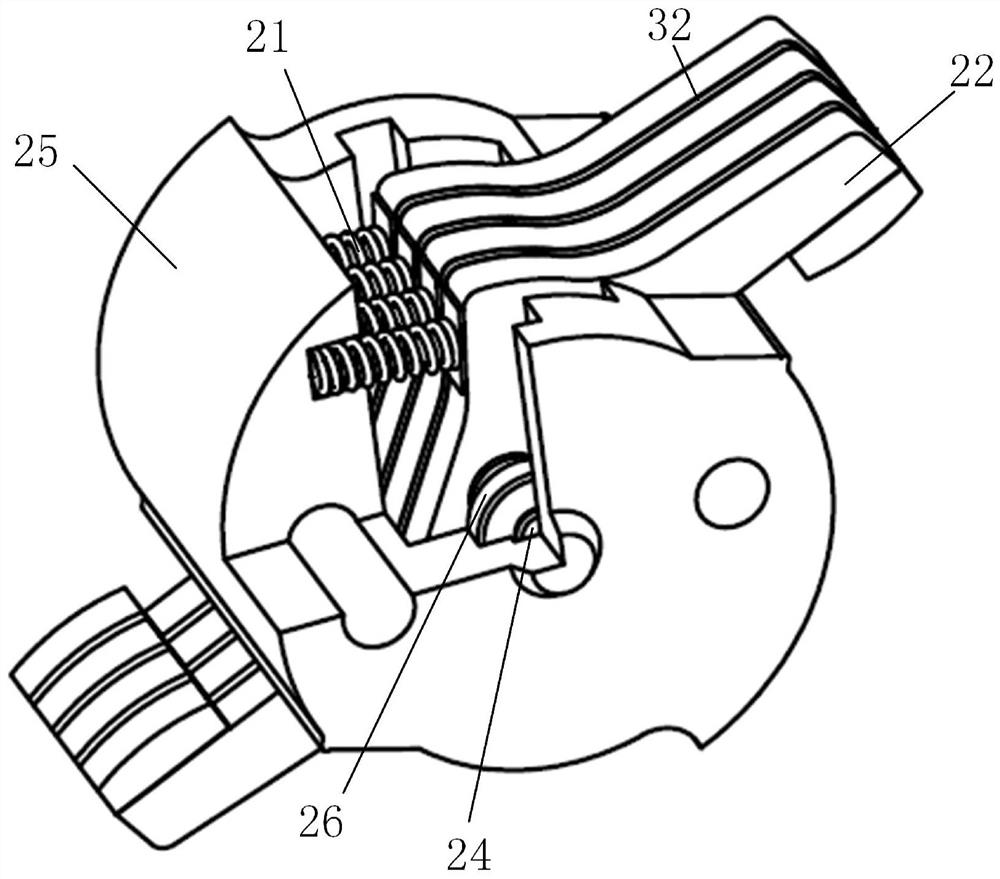

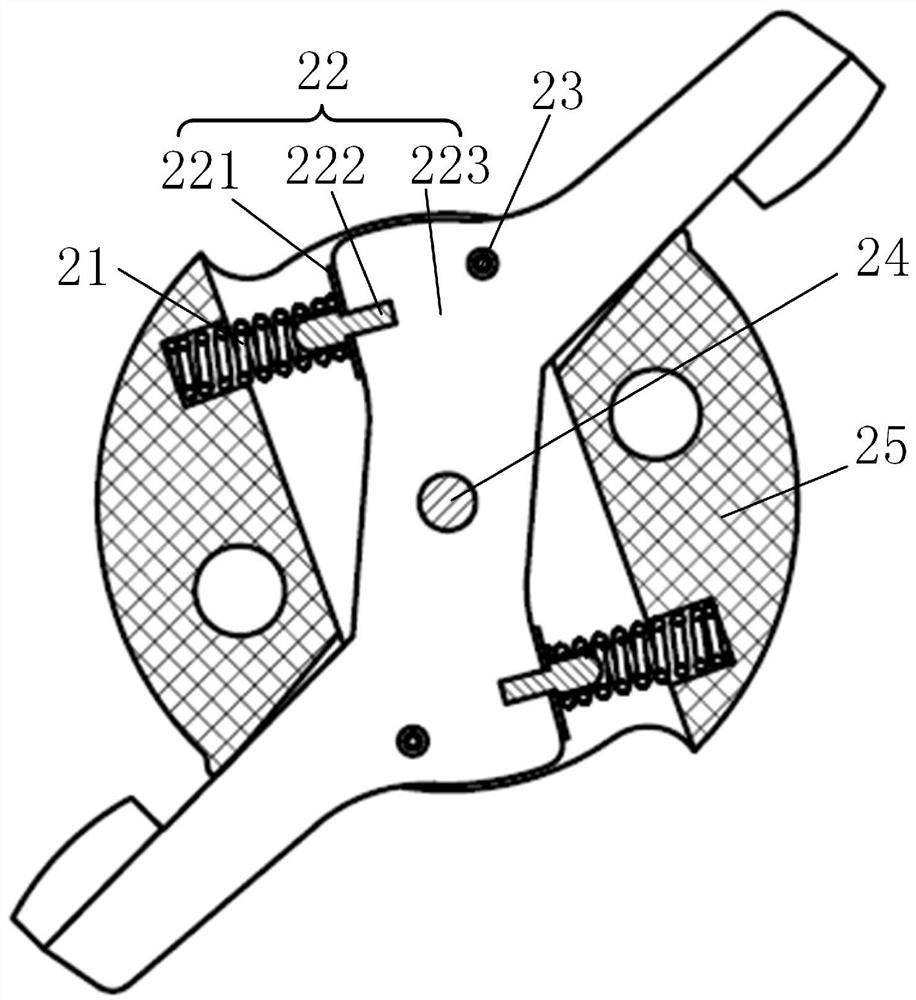

[0031] The purpose of the present invention is to overcome the existing rotary contact structure: (1) the temperature rise is too high; (2) the short-term tolerance is low; (3) the same contact finger is difficult to be centered and installed consistently, and double-break contact The simultaneity is poor; (4) The manufacturing and assembly requirements are high; (4) The contact spring force value is too large, and the contact bracket is easy to collapse. The provided multi-finger moving contact of the molded case circuit breaker adopts symmetrical double compression springs. Provide contact pressure, improve the contact spring force arm, can greatly reduce the spring force of each contact spring while ensuring the contact pressure Cracked head bracket insulation. The contact rod is installed on the contact bracket through the rotating shaft, which ensures t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com