a step drill

A technology of stepped drill bits and cutting parts, applied in drill repairing, drilling tool accessories, drilling/drilling equipment, etc., can solve problems such as waste of resources, achieve rapid maintenance and replacement, easy and convenient locking and releasing process, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

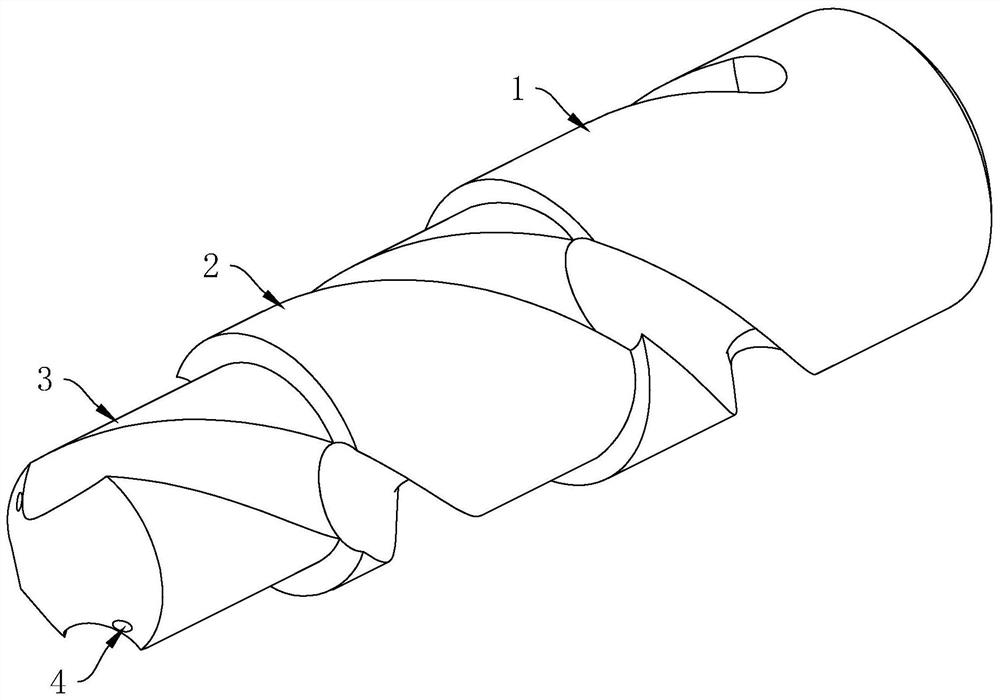

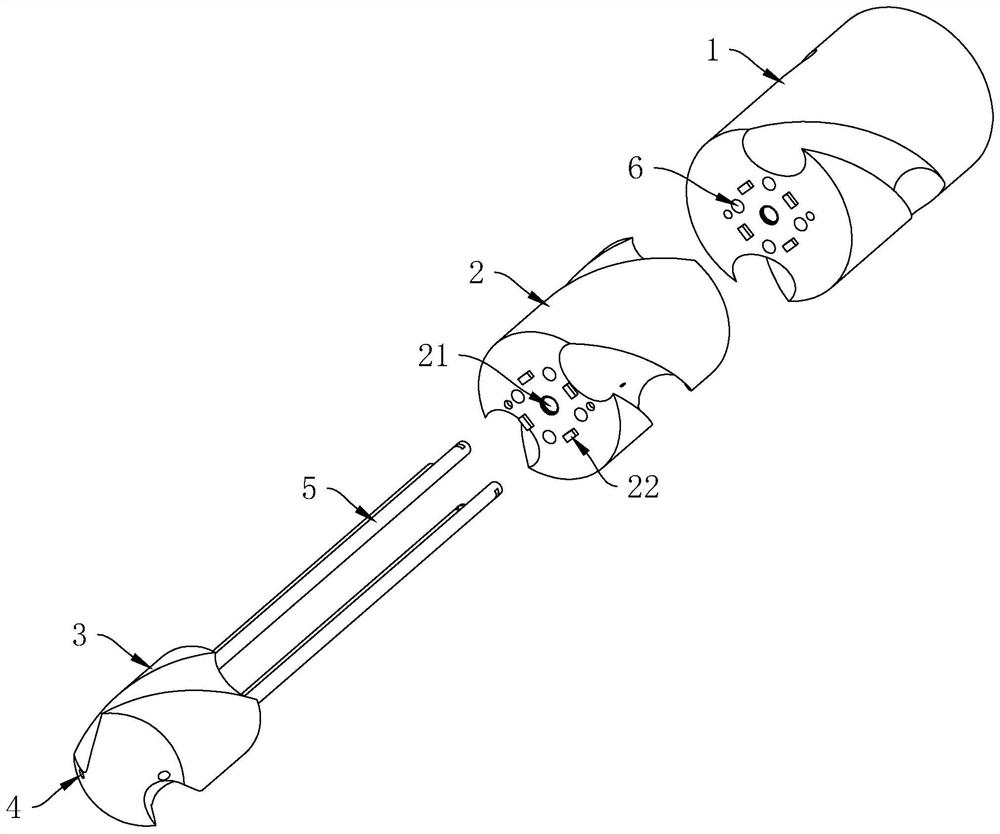

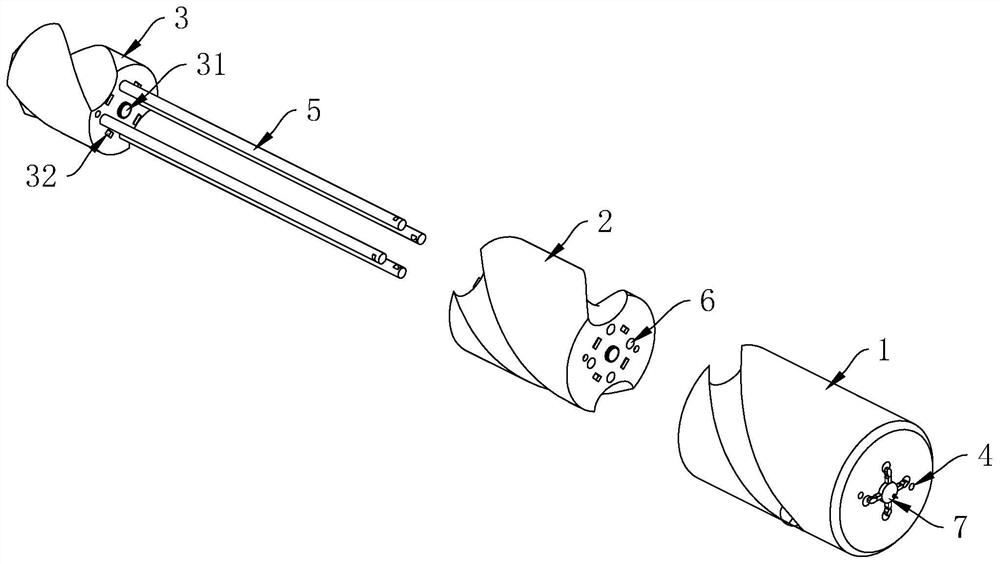

[0036] Such as figure 1 , figure 2 As shown, a step drill bit includes a clamping part 1, and one end of the clamping part 1 is provided with a first cutting part 2 and a second cutting part 3 in sequence, and the diameter of the first cutting part 2 is larger than that of the second cutting part 3 diameter.

[0037] Such as figure 1 , figure 2 As shown, a pair of cooling flow passages 4 disposed opposite to each other penetrate through the clamping portion 1 , the first cutting portion 2 and the second cutting portion 3 , and the pair of cooling flow passages 4 are arranged in a double helix shape.

[0038]When the above-mentioned drill bit is used, since the diameter of the first cutting part 2 is greater than that of the second cutting part 3, the workpiece can be processed by using the first cutting part 2 and the second cutting part 3, so that a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com