Buckle feeder for tying machine

A binding machine and buckle feeding technology, which is applied in external support, transportation packaging, packaging, etc., can solve the problems of uncontrollable aluminum buckle feeding volume, increase production cost, and affect binding efficiency, so as to reduce the risk of jamming and facilitate The effect of feeding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

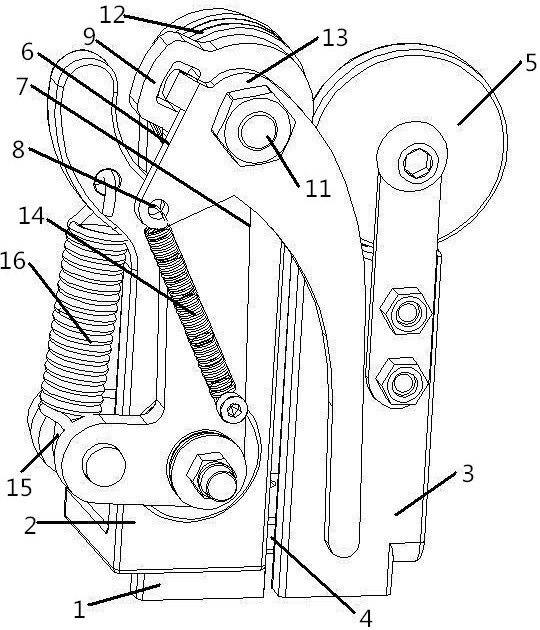

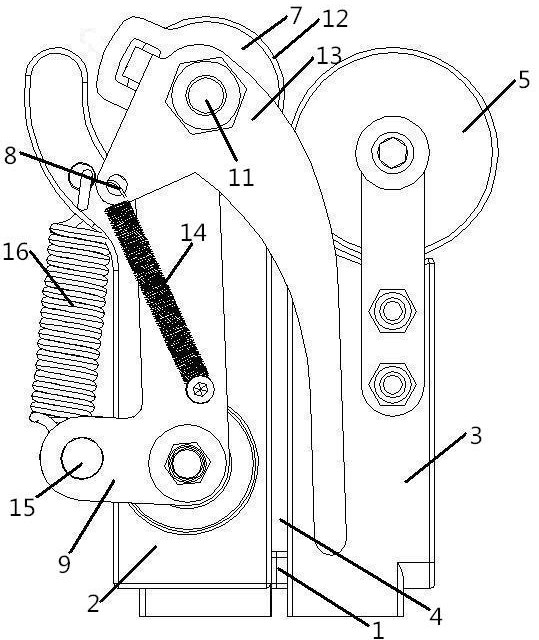

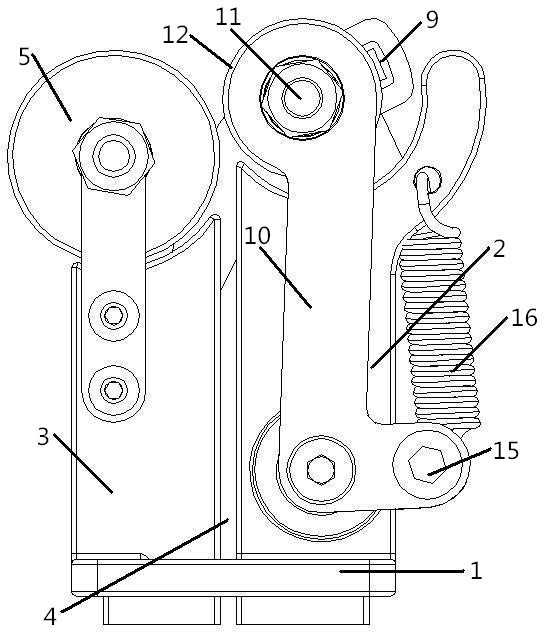

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] see Figure 1-Figure 3 , a buckle feeder for a tie machine, comprising a base 1, a left column 2 and a right column 3 are fixedly installed at both ends of the base 1 respectively, and an aluminum button passing material is formed between the left column 2 and the right column 3 Channel 4, the top of the right column 3 is provided with a freely rotatable guide wheel 5, the top of the left column 2 is provided with an aluminum buckle pushing device 6, and the aluminum buckle pushing device 6 includes a roller mechanism 7 capable of driving the aluminum buckle forward And the dial device 8 that controls the operation of the roller mechanism 7.

[0018] The roller mechanism 7 includes a front vertical plate 9 and a rear vertical plate 10 on both sides of the left column 2, a transverse shaft 11 and a roller 12. Connected togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com