A kind of aluminum alloy powder material for 3D printing and its preparation method and application

A technology of 3D printing and powder materials, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problem of poor stress corrosion resistance, strength and elongation to be improved, tensile strength and elongation can not be balanced, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

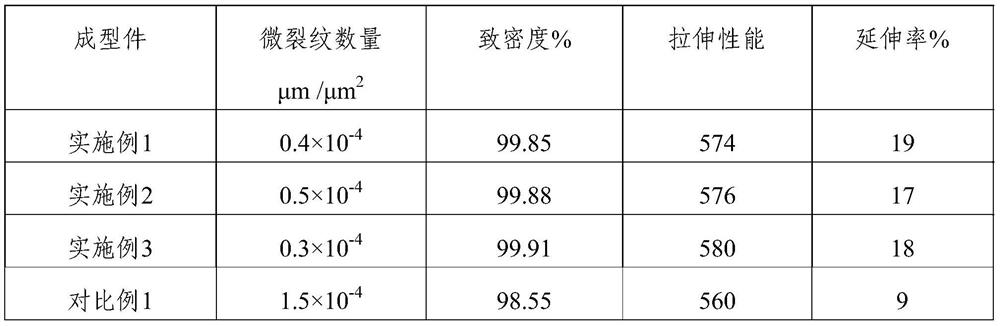

Embodiment 1

[0033]A special aluminum alloy powder for SLM printing, containing the following components in mass percentage: Mg: 7.5wt%; Sc: 0.55wt%; Zr: 0.27wt%; Mn: 0.4wt%; Fe: 0.06wt%; Ni : 0.06wt%; Si: 0.65wt.%; Zn: 0.07wt%; Cr: 0.08wt%; other trace elements include Er and Ce, the total content is 0.05wt%, and the balance is Al.

[0034] The total content of Si+Mn is 1.05wt.%;

[0035] The mass ratio of Si / Mn is 1.625;

[0036] The total content of Si+Mg is 8.15wt.%;

[0037] The mass ratio of Si / Mg is 0.087;

[0038] The mass ratio of Sc / Zr is 2.037;

[0039] Its preparation steps are as follows:

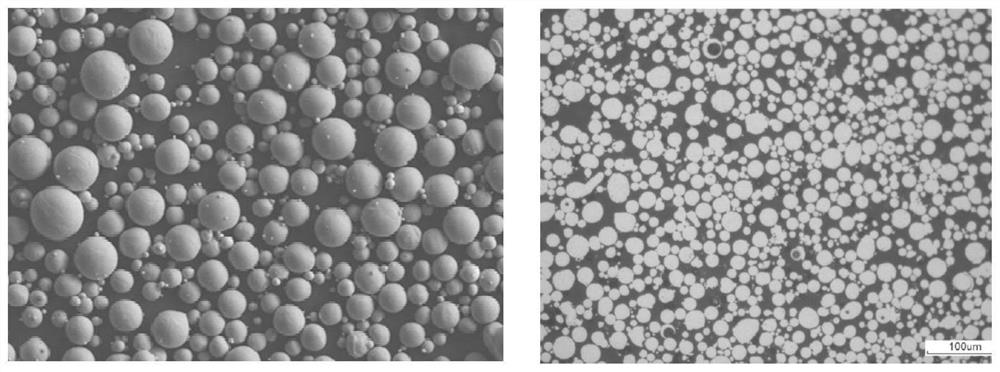

[0040] Extract the raw materials from the above components according to the set mass ratio. The raw materials are extracted in the form of pure alloy or intermediate alloy. The extracted raw materials are directly put into the vacuum melting crucible in a certain order, and the vacuum induction melting-inert gas atomization system is adopted. powder, and then the obtained powder is sub...

Embodiment 2

[0050] A special aluminum alloy powder for SLM printing, containing the following components in mass percentage: Mg: 6.5wt%; Sc: 0.65wt%; Zr: 0.33wt%; Mn: 0.15wt%; Fe: 0.05wt%; Ni Si: 0.8%; Zn: 0.08wt%; Cr: 0.06wt%; other trace elements include Er and Ti, the total content is 0.06wt%, and the balance is Al.

[0051] The total content of Si+Mn is 0.95wt.%;

[0052] The mass ratio of Si / Mn is 5.33;

[0053] The total content of Si+Mg is 7.3wt.%;

[0054] The mass ratio of Si / Mg is 0.123;

[0055] The mass ratio of Sc / Zr is 1.97;

[0056] Its preparation steps are as follows:

[0057] Extract the raw materials from the above components according to the set mass ratio. The raw materials are extracted in the form of pure alloy or intermediate alloy. The extracted raw materials are directly put into the vacuum melting crucible in a certain order, and the vacuum induction melting-inert gas atomization system is adopted. powder, and then the obtained powder is subjected to vibrat...

Embodiment 3

[0066] A special aluminum alloy powder for SLM printing, containing the following components in mass percentage: Mg: 8.5wt%; Sc: 0.45wt%; Zr: 0.22wt%; Mn: 0.5wt%; Fe: 0.04wt%; Ni : 0.08wt%; Si: 0.55wt.%; Zn: 0.09wt%; Cr: 0.05wt%; other trace elements include Sr, Ti and Ce, the total content is 0.06wt%, and the balance is Al.

[0067] The total content of Si+Mn is 1.05wt.%;

[0068] The mass ratio of Si / Mn is 1.1;

[0069] The total content of Si+Mg is 9.05wt.%;

[0070] The mass ratio of Si / Mg is 0.065;

[0071] The mass ratio of Sc / Zr is 2.045;

[0072] Its preparation steps are as follows:

[0073] Extract the raw materials from the above components according to the set mass ratio. The raw materials are extracted in the form of pure alloy or intermediate alloy. The extracted raw materials are directly put into the vacuum melting crucible in a certain order, and the vacuum induction melting-inert gas atomization system is adopted. powder, and then the obtained powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com