Hot isostatic pressing method for relieving low plasticity of selective laser melting (SLM) magnesium alloy

A hot isostatic pressing and laser melting technology, applied in the field of alloy materials, can solve the problems of affecting the density, the softness of magnesium alloys, and the difficulty of the research process, so as to reduce the production cost and difficulty, improve the plastic elongation, and stabilize the process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Before the experiment, the molding cavity was filled with argon gas to ensure that the oxygen content was controlled below 10ppm; the selective laser melting parameters were set to laser power 150W, scanning speed 400mm / s, scanning distance 0.06mm, powder layer thickness 0.04mm, The scanning strategy is "zigzag", and the adjacent two layers of lasers rotate 90° clockwise;

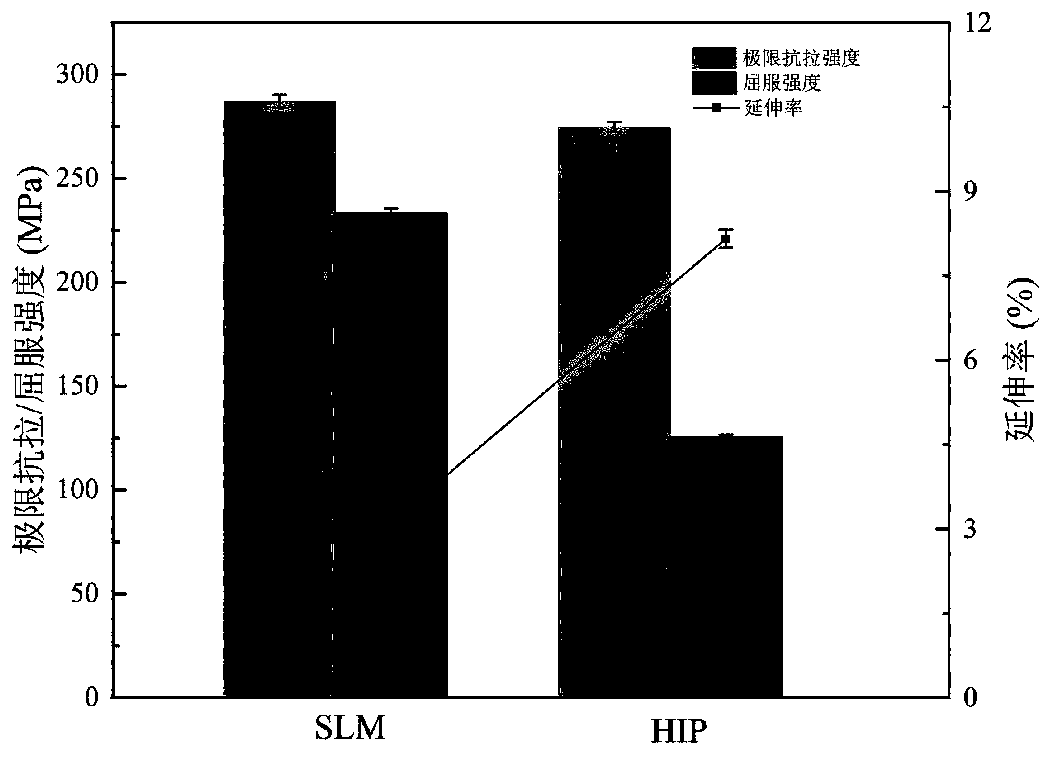

[0031] (2) Fill the hot isostatic pressing furnace with argon gas with a purity of 99.99%, a heating rate of 10 degrees per minute, a set temperature of 450 ° C, a pressure of 103 Mpa, heat preservation for 3 hours, a cooling rate of 15 degrees per minute, and hot isostatic pressing The post-plastic elongation is increased to 8.2%, which is 160% higher than that of the selective laser melting state. The strength, plasticity and SLM state samples of this material are compared in the attached figure 1 .

Embodiment 2

[0033] (1) Before the experiment, the molding cavity was filled with argon gas to ensure that the oxygen content was controlled below 10ppm; the selective laser melting parameters were set to laser power 150W, scanning speed 400mm / s, scanning distance 0.06mm, powder layer thickness 0.04mm, The scanning strategy is "zigzag", and the adjacent two layers of lasers rotate 90° clockwise.

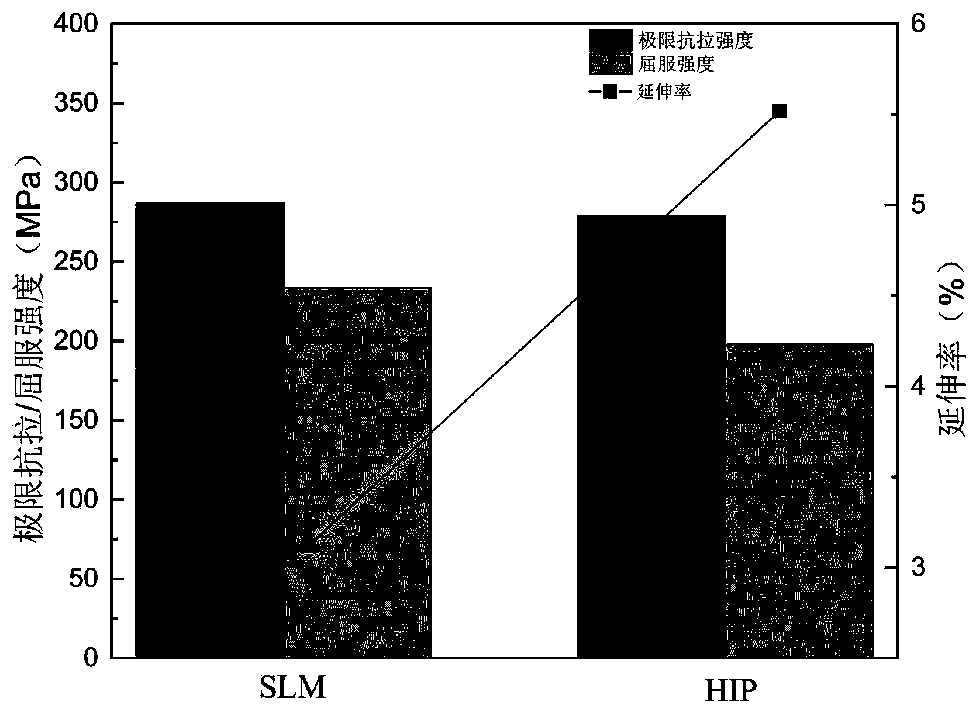

[0034] (2) Fill the hot isostatic pressing furnace with argon gas with a purity of 99.99%, a heating rate of 10 degrees per minute, a temperature of 350 ° C, a pressure of 103 Mpa, a heat preservation of 3 hours, and a cooling rate of 15 degrees per minute. After hot isostatic pressing The plastic elongation is increased to 5.5%, which is 77% higher than that of the selective laser melting state. The strength, plasticity and SLM state samples of this material are compared in the attached figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com