Method for preparing Mg-Al-Zn-Mn-Cu multi-component alloy through combination of three-dimensional ultrasound and sound field detection

A multi-element alloy and three-dimensional ultrasonic technology, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problem of insufficient ultrasonic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The preparation method of the present invention is simple, and can control the solidification structure and application performance of the alloy. The quality of the alloy elements in the obtained multi-element magnesium alloy is accurate and evenly distributed, and its tensile strength, tensile plasticity, hardness and damping performance are all significantly high. Castings prepared under normal casting conditions.

[0093] The present invention provides a device for preparing the Mg-Al-Zn-Mn-Cu multi-element alloy described in the above technical solution, the device comprising three ultrasonic vibration components.

[0094] In the present invention, the ultrasonic fields generated by the three ultrasonic vibration components are preferably three-dimensionally orthogonal to each other.

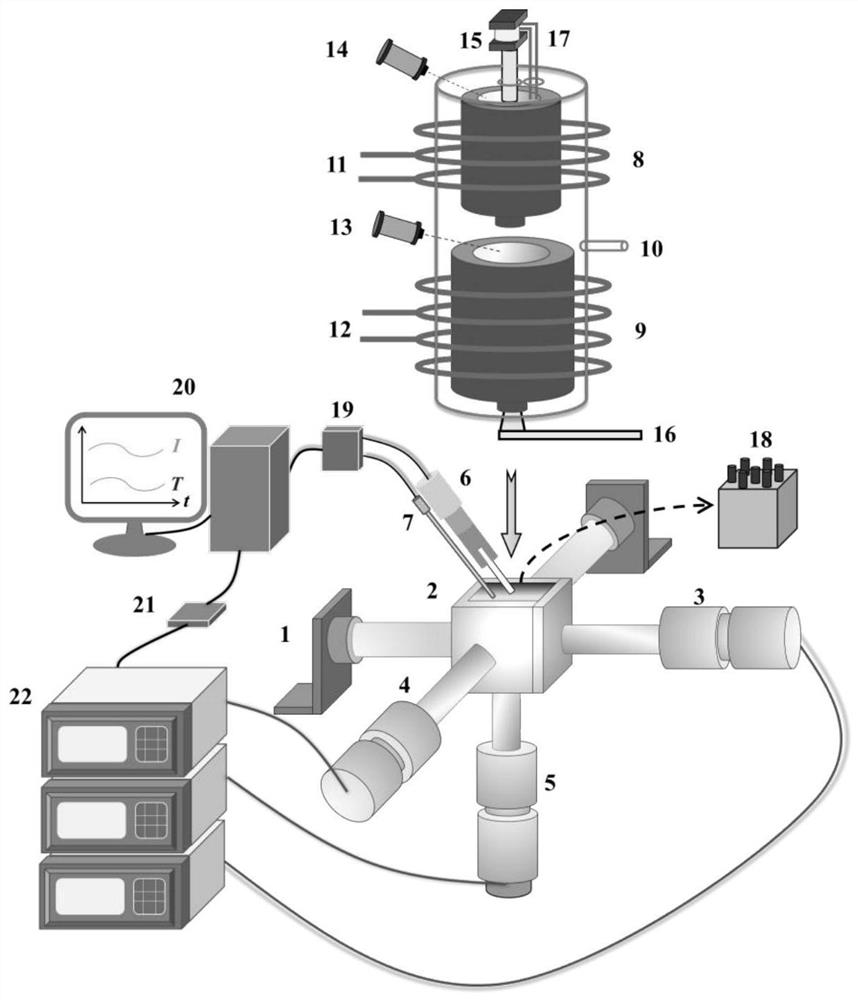

[0095] Such as figure 1 As shown, in one embodiment of the present invention, the device includes a push rod 1, a mold 2, an X-axis ultrasonic vibration assembly 3, a Y-axis ultrason...

Embodiment 1

[0127] Such as figure 1 As shown, the device provided by the present invention includes a reverse thrust rod 1, a casting mold 2, an X-axis ultrasonic vibration assembly 3, a Y-axis ultrasonic vibration assembly 4, a Z-axis ultrasonic vibration assembly 5, a waveguide rod 6, a thermocouple 7, and an upper graphite crucible 8 , lower graphite crucible 9, quartz gas shield 10, upper high-frequency melting device 11, lower high-frequency melting device 12, upper infrared temperature measuring device 13, lower infrared temperature measuring device 14, upper plugging device 15, lower plugging device 16. Flow monitoring device 17, preheating device 18, sound field and temperature sensor and signal acquisition circuit 19, computer 20, acquisition card 21, transducer power supply 22;

[0128] The outer wall of the casting mold 2 is close to the reverse push rod 1, and the X-axis ultrasonic vibration assembly 3 and the Y-axis ultrasonic vibration assembly 4 are pressed against two mutu...

Embodiment 2

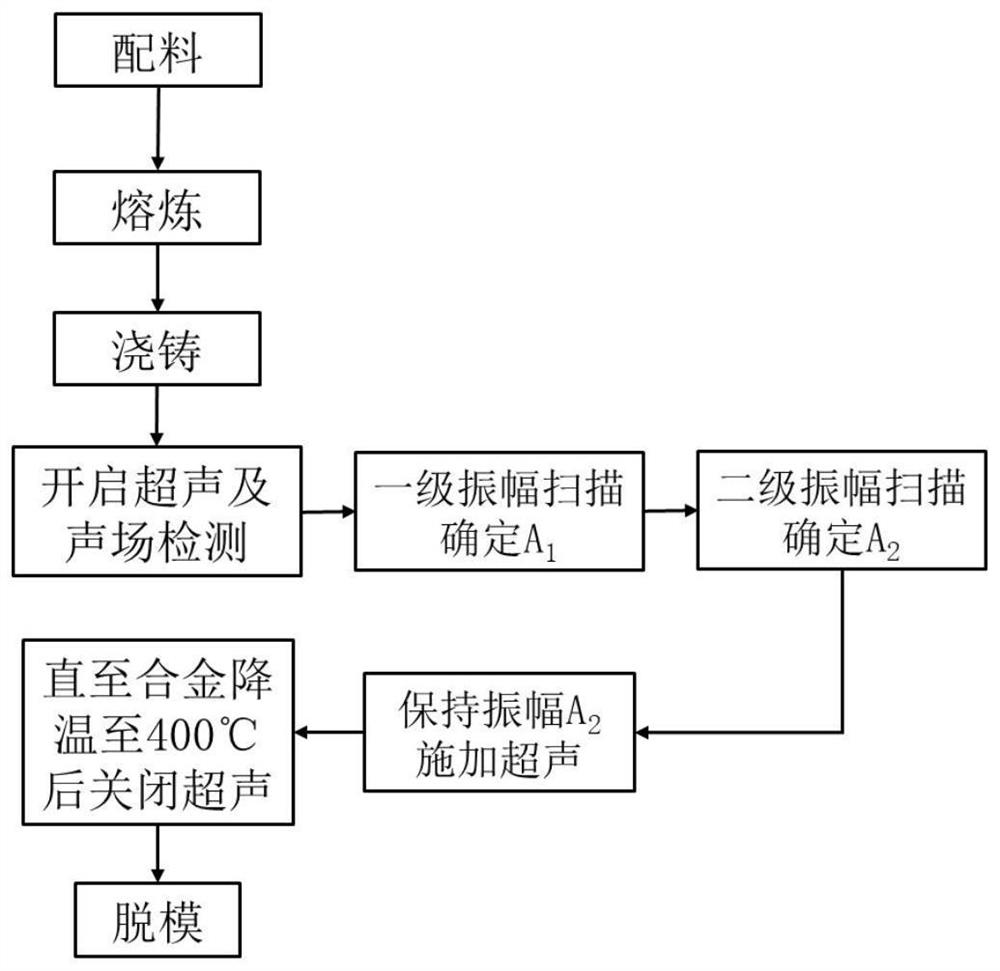

[0137] A method for preparing a Mg-Al-Zn-Mn-Cu multi-element alloy by combining three-dimensional ultrasound with sound field detection, comprising the following steps:

[0138] (1) After mixing the raw materials of the master alloy, carry out the first smelting to obtain the first melt; in terms of 100wt.% of the master alloy, the raw materials of the master alloy are: 20wt.% Zn, 10wt.% Mn, 10wt.% of Cu and the balance of Al; the temperature of the first melt is 1300 ° C; the mass percentage of the multi-element magnesium alloy is 100wt.%, and the mass of the master alloy is 5.0wt.%.

[0139] After mixing 5.5wt.% Al and the remainder of Mg, a second smelting is carried out to obtain a second melt; the temperature of the second melt is 700°C;

[0140] The first melt is mixed with the second melt for the third smelting to obtain an alloy melt; the temperature of the third smelting is 720°C, and the holding time of the third smelting is 3min;

[0141] The first smelting, the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com