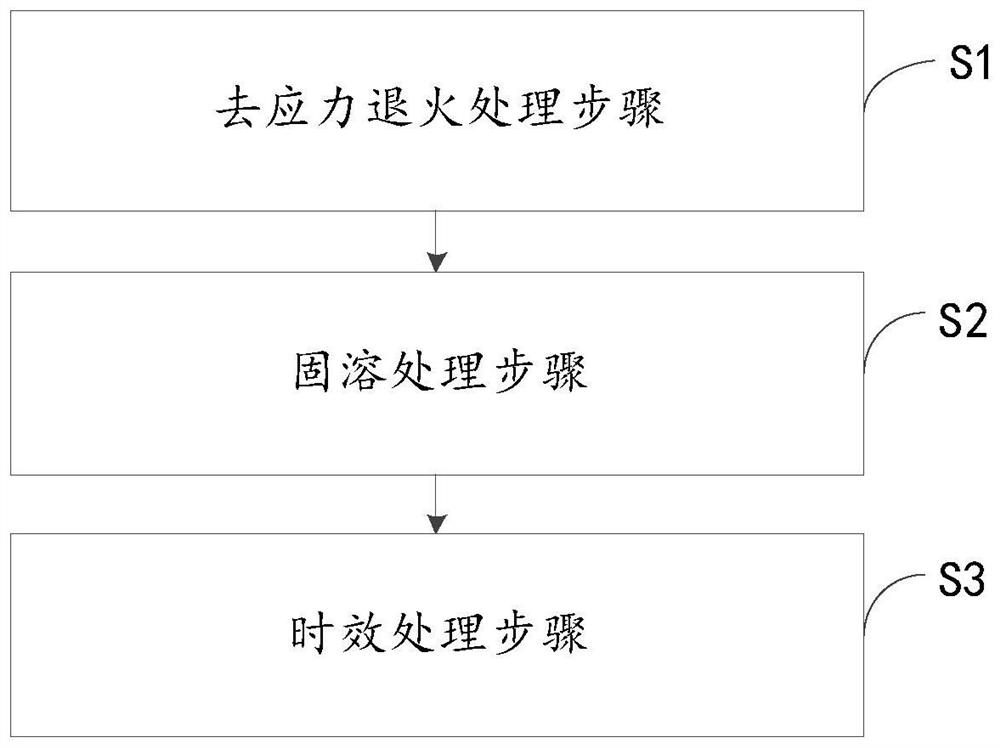

Heat treatment method for selective laser melting of AlSi10Mg alloy

A technology of selective laser melting and heat treatment, which is applied in additive manufacturing, additive processing, etc., can solve the problems of insignificant effect of microstructure regulation and low stability of mechanical properties, and can meet the requirements of performance stability and toughness, improve The effect of plastic elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

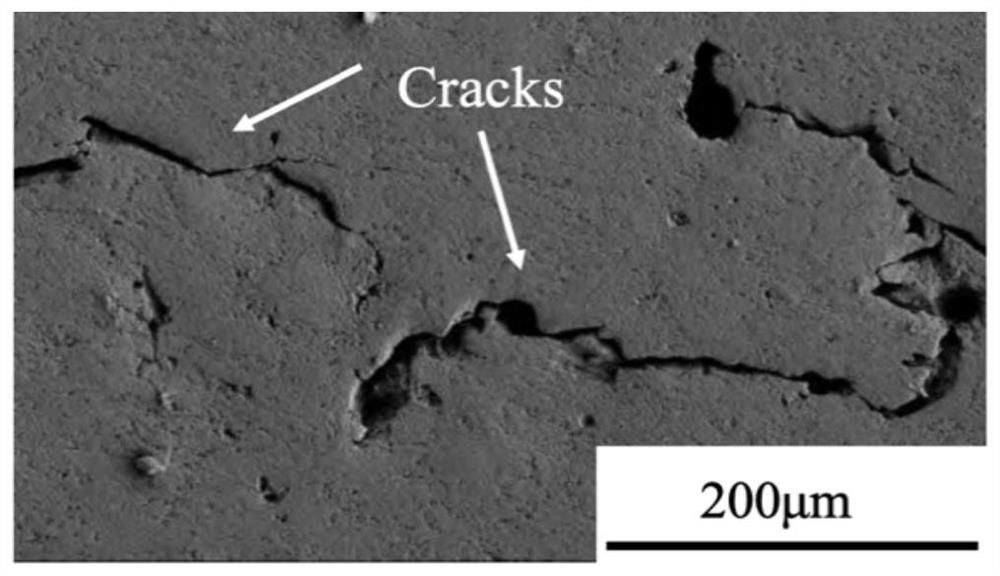

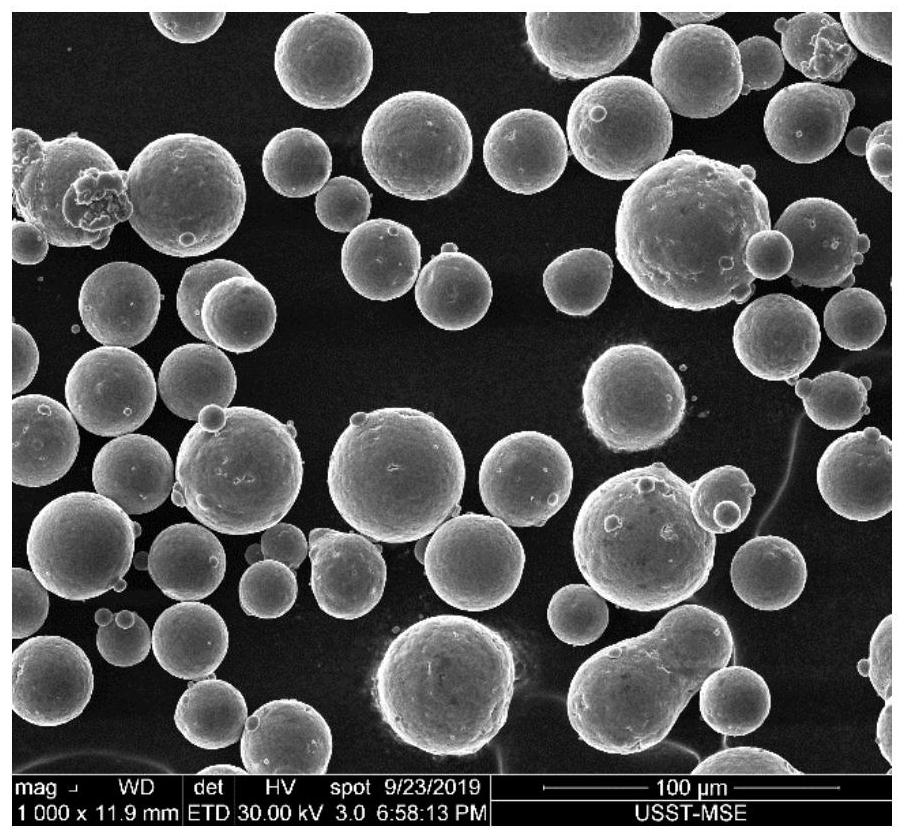

[0057] This embodiment provides a heat treatment method for selective laser melting of AlSi10Mg alloy, using AlSi10Mg alloy raw material powder with a particle size of 20-63 μm and an angle of repose of 38° for selective laser melting. The microscopic morphology of AlSi10Mg alloy raw material powder is as follows: image 3 As shown, the SEM microstructure photos of the deposited aluminum-silicon alloy components are as follows Figure 4a As shown, among them, Figure 4b for Figure 4a The high-magnification topography of P1 in the middle, Figure 4c for Figure 4a The high-magnification topography of P2 in the middle.

[0058] refer to Figure 4b , the overlap of the molten pool is composed of three morphologies: coarse-grained zone 1, heat-affected zone (HAZ) 2 and fine-grained zone 3. The coarse-grained zone 3 is located in the center of the remelting zone of the molten pool. The grains in this zone are re-nucleated and grown after secondary melting. The heat-affected ...

Embodiment 2

[0072] This embodiment provides a heat treatment method for selective laser melting of AlSi10Mg alloy, the difference is that AlSi10Mg alloy raw material powder with a particle size of 25-53 μm and an angle of repose of 36° is used for selective laser melting.

[0073] S21) Stress relief annealing treatment step: heat the heat treatment furnace to 280°C at a heating rate of 4°C / min, put the aluminum-silicon alloy component into the heat treatment furnace for stress relief annealing treatment, and heat it for 2.5 hours. The aluminum-silicon alloy component is cooled to room temperature with the furnace at a cooling rate of 8°C / min.

[0074] S22) Solution treatment step: Heat the heat treatment furnace to 535 °C at a heating rate of 8 °C / min, place the aluminum-silicon alloy components that have been subjected to stress relief annealing in the heat treatment furnace for solution treatment, and heat them for 1.5 hours. The treated aluminum-silicon alloy component was taken out, p...

Embodiment 3

[0082] This embodiment provides a heat treatment method for selective laser melting of AlSi10Mg alloy, the difference is that AlSi10Mg alloy raw material powder with a particle size of 22-60 μm and an angle of repose of 34° is used for selective laser melting.

[0083] S31) Stress relief annealing treatment step: heat the heat treatment furnace to 240°C at a heating rate of 6°C / min, put the aluminum-silicon alloy component into the heat treatment furnace for stress relief annealing treatment, and heat it for 4 hours. The silicon alloy component is cooled to room temperature with the furnace at a cooling rate of 7°C / min.

[0084] S32) Solution treatment step: Heat the heat treatment furnace to 520 °C at a heating rate of 7 °C / min, place the aluminum-silicon alloy components that have been subjected to stress relief annealing in the heat treatment furnace for solution treatment, and heat them for 1.6 hours. The treated aluminum-silicon alloy components were taken out, and placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com