Large-scale mold module and method for manufacturing same

A manufacturing method and mold technology, applied in the direction of manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of not being able to meet the requirements of large-scale plastic mold module manufacturing, high module manufacturing costs, and oil mist emission, so as to improve product competitiveness And the effect of occupying share, reasonable ratio and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. A large-scale plastic mold module, the weight percentage of its chemical composition is: C 0.23wt%, Si0.12wt%, Mn 1.59wt%, Cr 1.30wt%, V 0.25wt%, Mo 0.63wt%, Ni 0.99wt%, S 0.011wt%, P 0.013wt%, the rest is Fe;

[0037] 2. After initial smelting in the electric arc furnace and scouring outside the furnace, it is cast into a large steel ingot of 25 tons; the steel ingot is heated in the forging heating furnace at a heating rate of 95 ℃ / h to 1200 ℃ and then kept for 6 hours; the forging temperature is 1110 ℃; The temperature is 950°C.

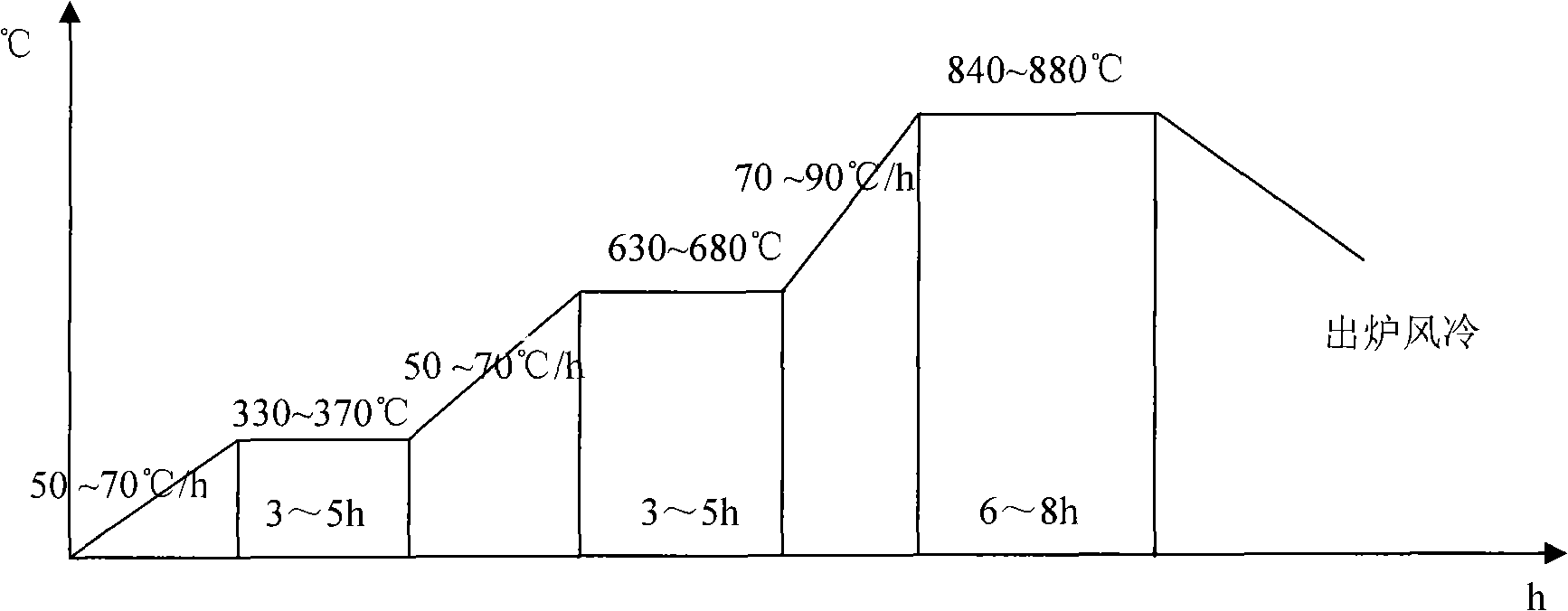

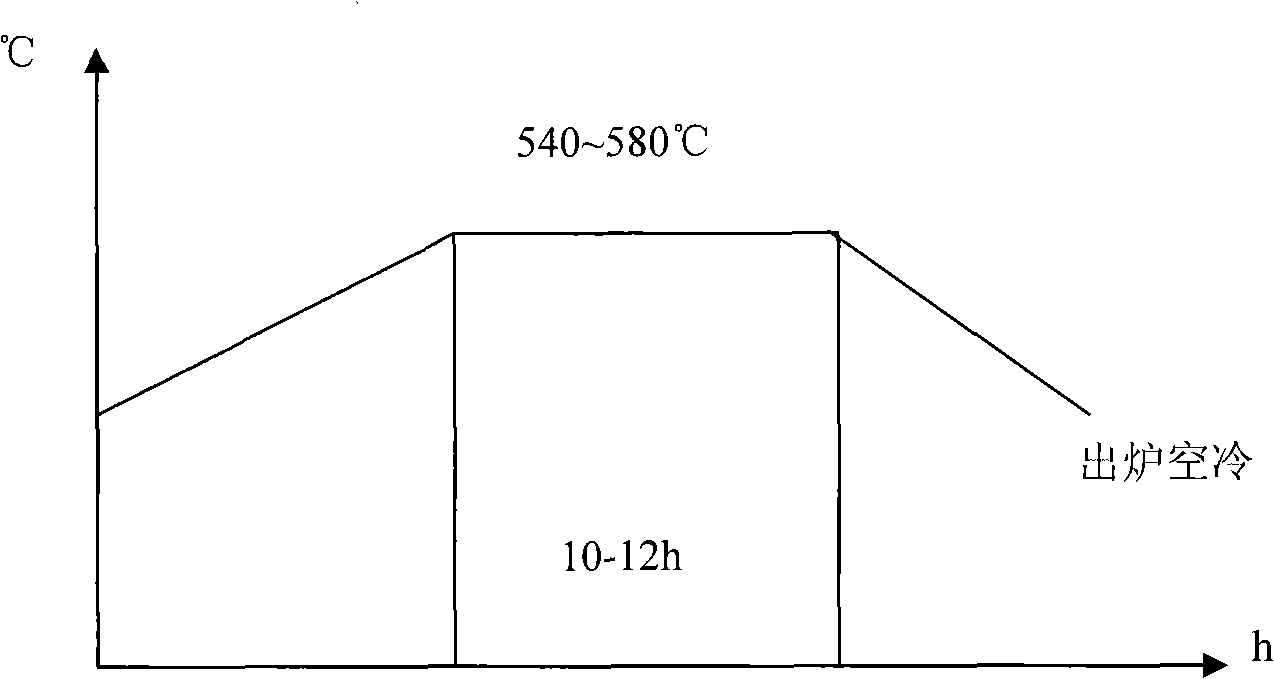

[0038] After forging, the pre-hardening heat treatment of the plastic mold module is carried out. First, the plastic mold module is placed in a quenching furnace and heated to 345°C at a heating rate of 55°C / h, then kept for 3.5 hours; then heated to 645°C at a heating rate of 55°C / h After holding for 3.5 hours; then heating to 855°C at a heating rate of 75°C / h and holding for 6.5 hours, then remove the quenching furnace and cool to room tem...

Embodiment 2

[0042] 1. A large-scale plastic mold module, the weight percentage of its chemical composition is: C 0.20wt%, Si0.08wt%, Mn 1.55wt%, Cr 1.35wt%, V 0.12wt%, Mo 0.60wt%, Ni 0.90wt%, S 0.015wt%, P 0.010wt%, the rest is Fe;

[0043] 2. After initial smelting and refining outside of the electric arc furnace, it is cast into a large steel ingot of 25 tons; the steel ingot is heated in the forging heating furnace at a heating rate of 80℃ / h to 1220℃ and then kept for 5 hours; the forging temperature is 1090℃; the forging temperature is stopped 900°C.

[0044] After forging, the pre-hardening heat treatment of the mold module is carried out. First, the mold module is placed in a quenching furnace and heated to 330°C at a heating rate of 50°C / h, and then kept for 3 hours; then heated to 650°C at a heating rate of 50°C / h After keeping the temperature for 4 hours; then heating to 850°C according to the heating rate of 70°C / h, then keeping it for 7 hours, then remove the quenching furnace and ...

Embodiment 3

[0048] 1. A large-scale plastic mold module, the weight percentage of its chemical composition is: C 0.22wt%, Si0.11wt%, Mn 1.70wt%, Cr 1.20wt%, V 0.35wt%, Mo 0.55wt%, Ni 1.20wt%, S 0.008wt%, P 0.020wt%, the rest is Fe;

[0049] 2. After initial smelting in the electric arc furnace and scouring outside the furnace, it is cast into a large steel ingot of 25 tons; the steel ingot is heated in the forging heating furnace at a heating rate of 120℃ / h to 1200℃ and then kept for 7 hours; the forging temperature is 1150℃; the forging temperature is stopped 850°C.

[0050] After forging, the pre-hardening heat treatment of the plastic mold module is performed. First, the plastic mold module is placed in a quenching furnace and heated to 370°C at a heating rate of 60°C / h, and then kept for 5 hours; then heated to 630°C at a heating rate of 70°C / h After keeping the temperature for 5 hours; then heating to 840°C according to the temperature increase rate of 80°C / h, then keeping it for 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com