Cylinder type gate structure

A gate and cylinder type technology, applied in the field of the cylinder type gate structure, can solve the problems of reducing the opening and closing force, unbalanced water load, etc., and achieve the effect of reducing the frequency of maintenance, reducing the loss of water head, and improving the efficiency of water diversion and power generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

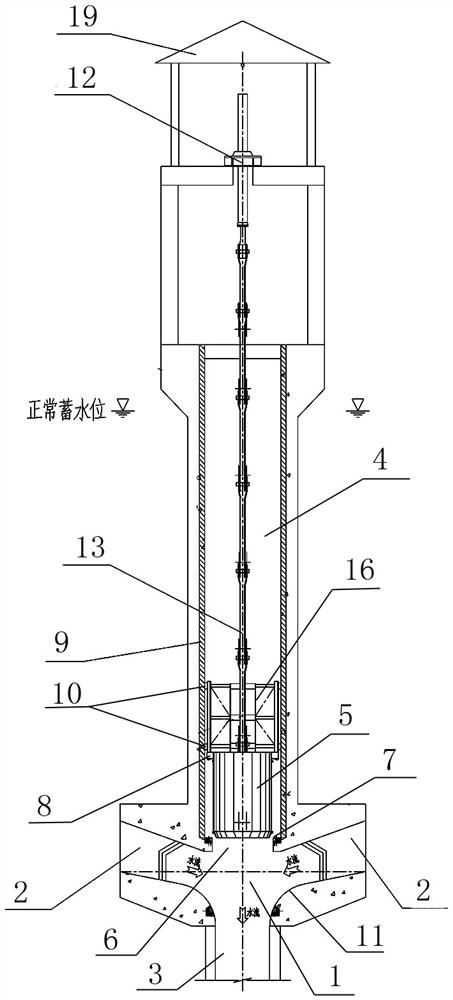

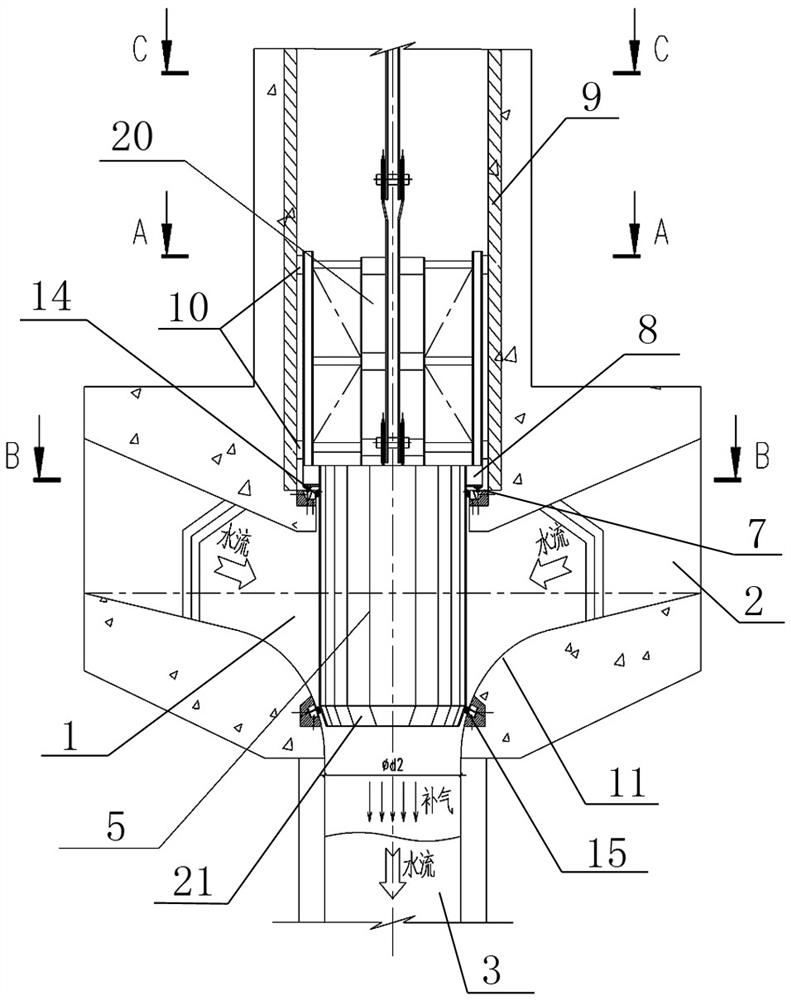

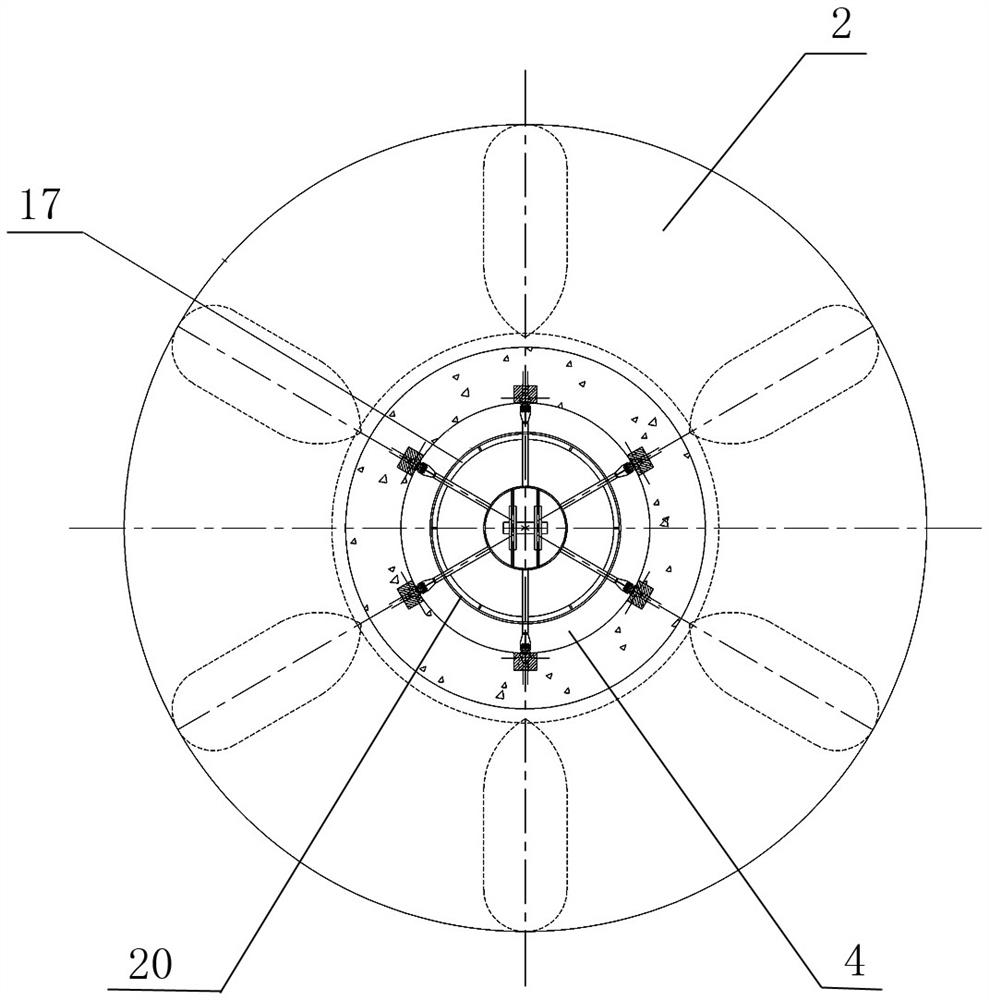

[0024] This embodiment is a cylindrical gate structure with a gate chamber, 6 water inlets are evenly arranged around the gate chamber, and the 6 water inlets are evenly distributed radially around the gate chamber, and the water inlets are from one end to the gate chamber. The connecting end of the chamber is arranged obliquely downward.

[0025] In this example, a water outlet vertically arranged and connected to the gate chamber is provided at the lower end of the gate chamber, and a smooth transition surface is formed on the lower inner wall of the gate chamber, between the water inlet and the water outlet below the gate chamber. The upper end of the gate chamber is provided with a gate well which is vertically arranged and communicated with the gate chamber below, and the lower end of the gate well is formed with a gate through hole with a diameter slightly smaller than the inner diameter of the gate well, and a ring of supporting steps is formed between the gate well and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com