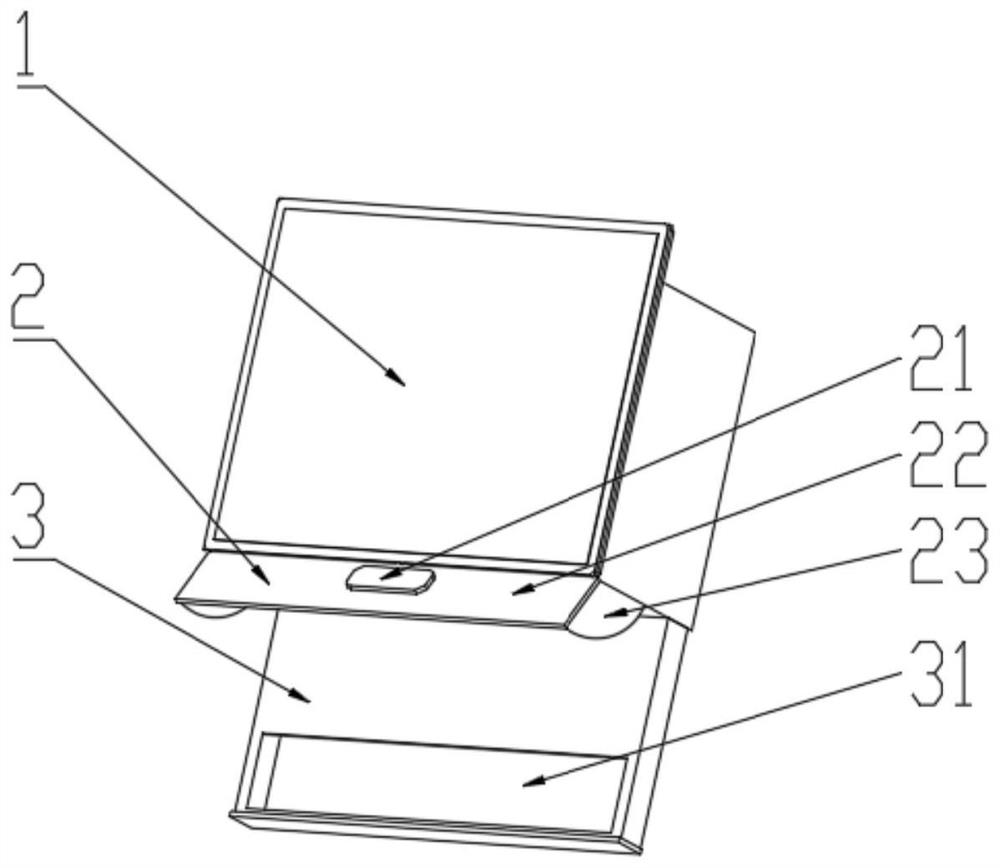

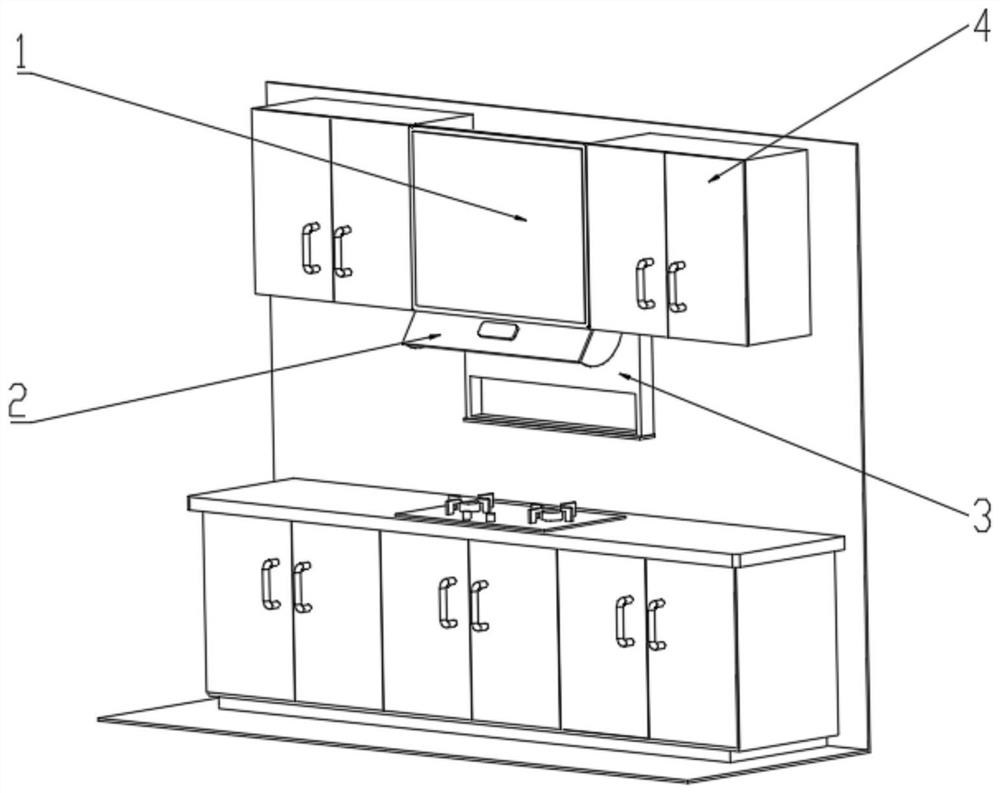

Range hood with turnover lifting mechanism and control method thereof

A technology of turning up and down and range hood, which is applied in the direction of oil fume removal, heating methods, household appliances, etc., can solve the problems of oil fume escape, achieve a large cooking space, improve the effect of oil smoke, improve the ability of oil fume processing and smoking effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

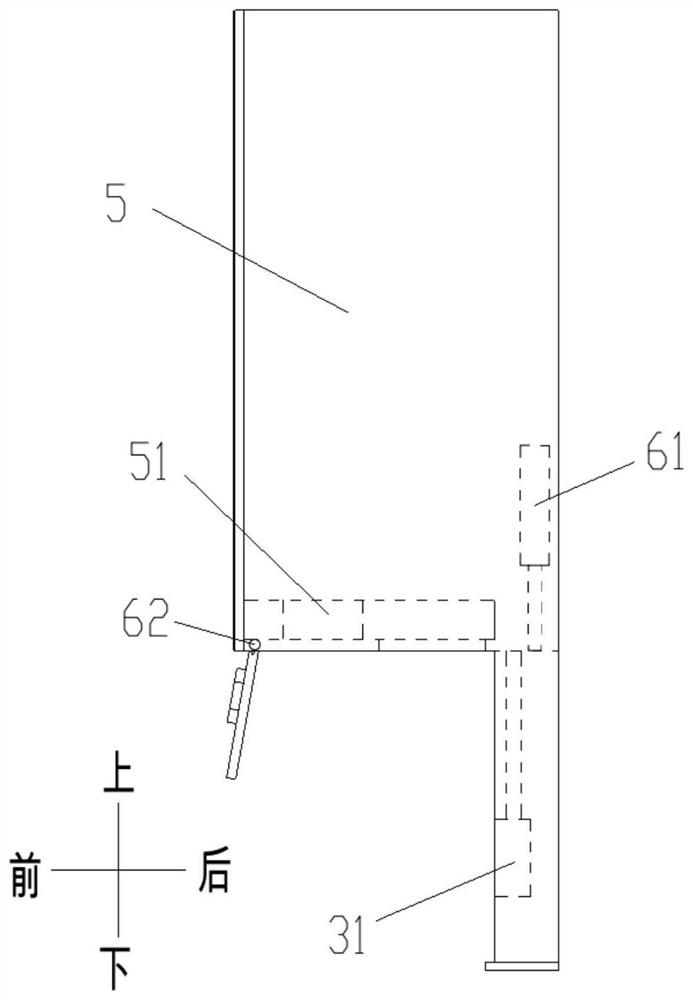

[0079] Embodiment one: if Figure 5 As shown, when the oil fume concentration is high, the bottom of the down extension plate is 300mm away from the cooktop, the flip angle of the flip plate is 124°, the bottom extension plate is at the preset minimum position, and the flip plate is at the preset maximum flip angle. best effect.

Embodiment 2

[0080] Embodiment two: if Figure 6 As shown, when the oil fume concentration is medium, the bottom of the extension plate is 350mm away from the cooktop, the flip angle of the flip plate is 112°, the bottom extension plate is at the preset middle position, and the flip plate is at the preset middle flip angle. Medium, in this case, the cooking space is large, the influence of the range hood on the cooking staff is small, and the oil during cooking is not easy to splash on the components of the range hood.

Embodiment 3

[0081] Embodiment three: as Figure 7 As shown, when the oil fume concentration is small, the bottom of the down extension plate is 400mm away from the cooktop, the flip angle of the flip plate is 100°, the bottom extension plate is at the preset highest position, the flip plate is at the preset minimum flip angle, the concentration of oil fume is small, and the oil fume With this setting, the cooker is sufficient to absorb the cooking fume, and the cooking space is larger, so the cooker hood has less impact on the cooking staff and the cooking action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com