Live pig slaughtering device

A kind of equipment and pig technology, applied in the field of slaughter, can solve the problems of unfavorable work for workers, reduced efficiency of pig slaughter, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

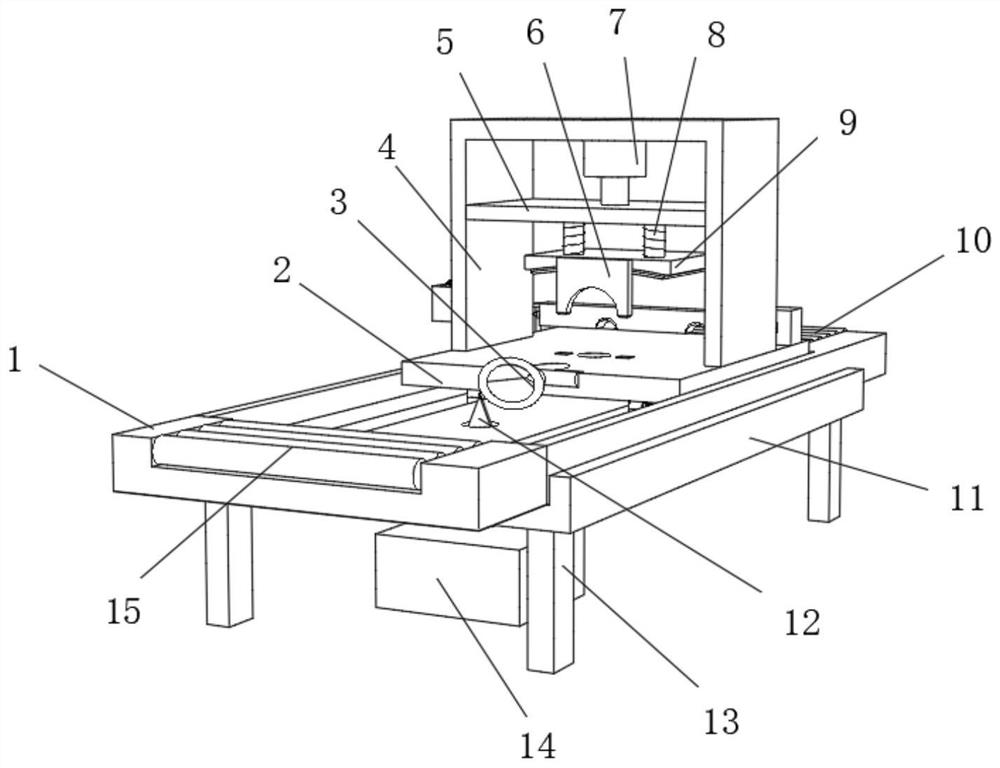

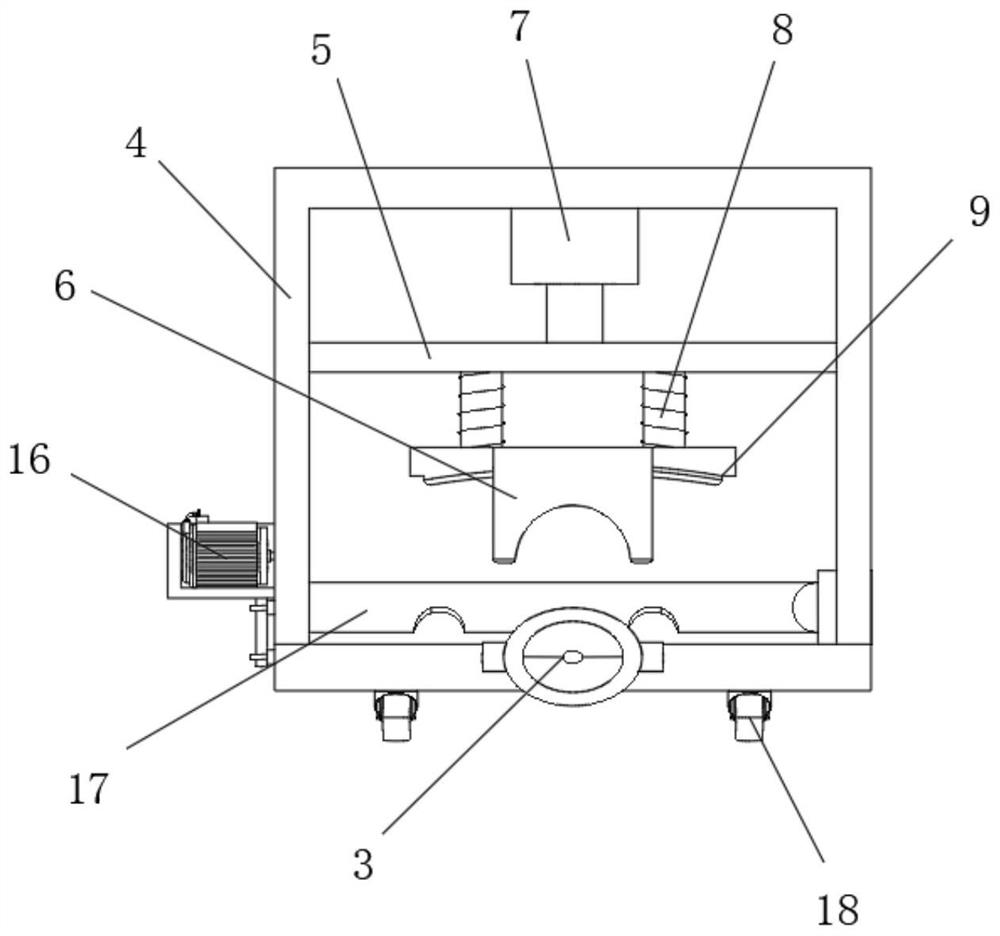

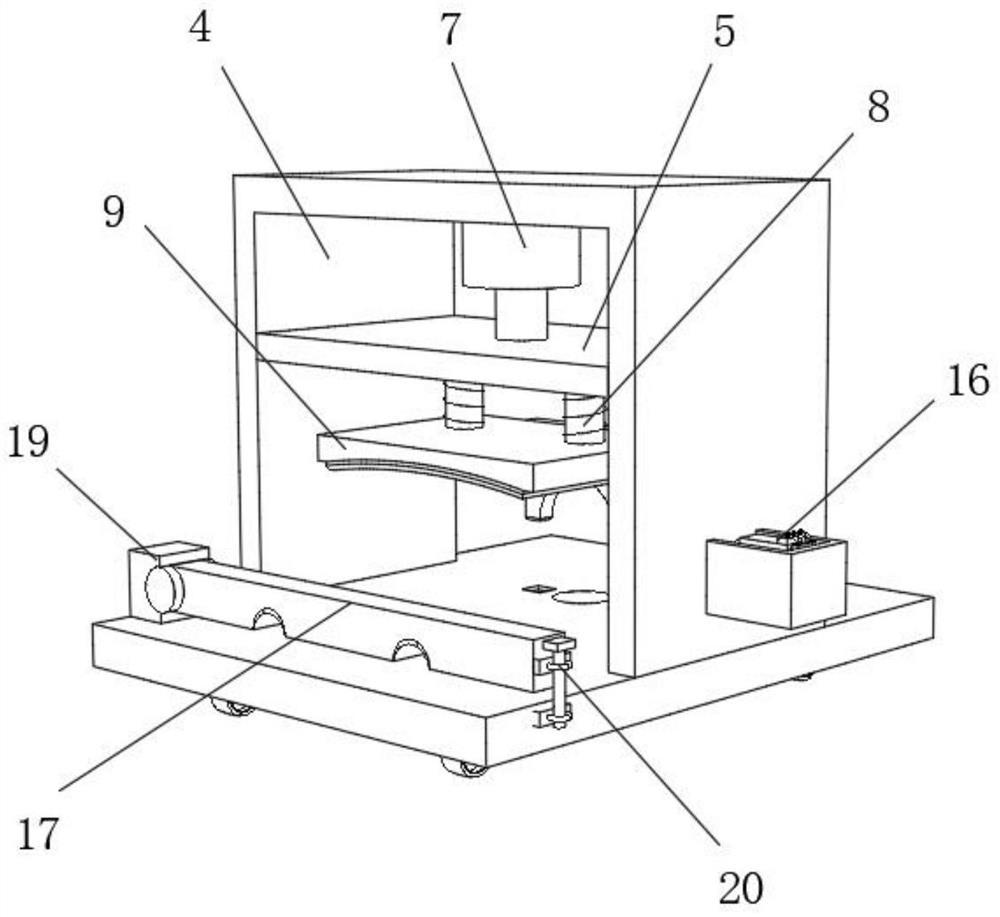

[0027] refer to Figure 1-4 , a pig slaughtering equipment, including a workbench 1, the top outer wall of the workbench 1 is provided with a chute, and the inner wall of the chute is slidably connected with a fixed seat 2, and the top outer wall of the fixed seat 2 is connected with a fixed frame 4 by screws, and The top inner wall of the fixed frame 4 is connected with the first hydraulic cylinder 7 by a rivet, and one end of the piston rod of the first hydraulic cylinder 7 is connected with the sliding plate 5 by a screw, and the outer wall of the bottom end of the sliding plate 5 is connected by two equidistant distributions by screws. connecting rod 8, and the bottom outer wall of connecting rod 8 is connected with body splint 9 by screw, and one side outer wall of body splint 9 is connected with head splint 6 by screw, one side outer wall of the top of fixed seat 2 The first rotating shaft is movably connected, and the outer wall of the first rotating shaft is sleeved wi...

Embodiment 2

[0034] refer to figure 1 , a kind of pig slaughtering equipment, compared with Embodiment 1, this embodiment also includes a first rectangular groove on the other side of the top of the workbench 1, and the inner wall of the first rectangular groove is movably connected with seven to nine Two equidistantly distributed feeding rollers 10, a side outer wall on the top of the workbench 1 is provided with a second rectangular groove, and the inwall of the second rectangular groove is movably connected with seven to nine equidistantly distributed discharge rollers 15.

[0035] Working principle: when the pig needs to be fed, the pig moves to the feed roller 10, and the feed roller 10 rotates to drive the pig forward. After the slaughter is completed, the pig moves from the fixed seat 2 to the discharge roller 15, and the discharge roller 15 The rotation drives the pig to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com