Multifunctional stretcher

A multifunctional, stretcher technology, applied in the field of medical equipment, can solve the problem of single function of the stretcher, achieve the effects of reducing labor intensity, saving manpower, and avoiding secondary injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

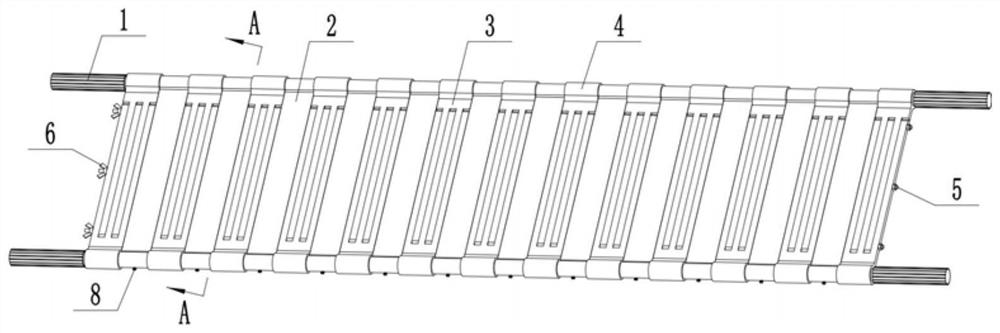

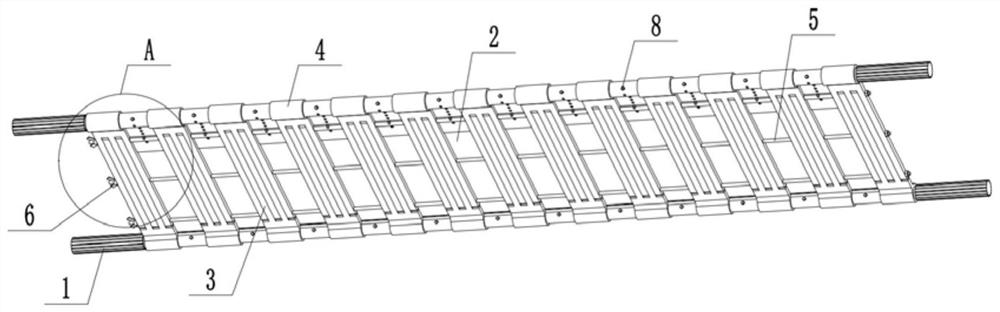

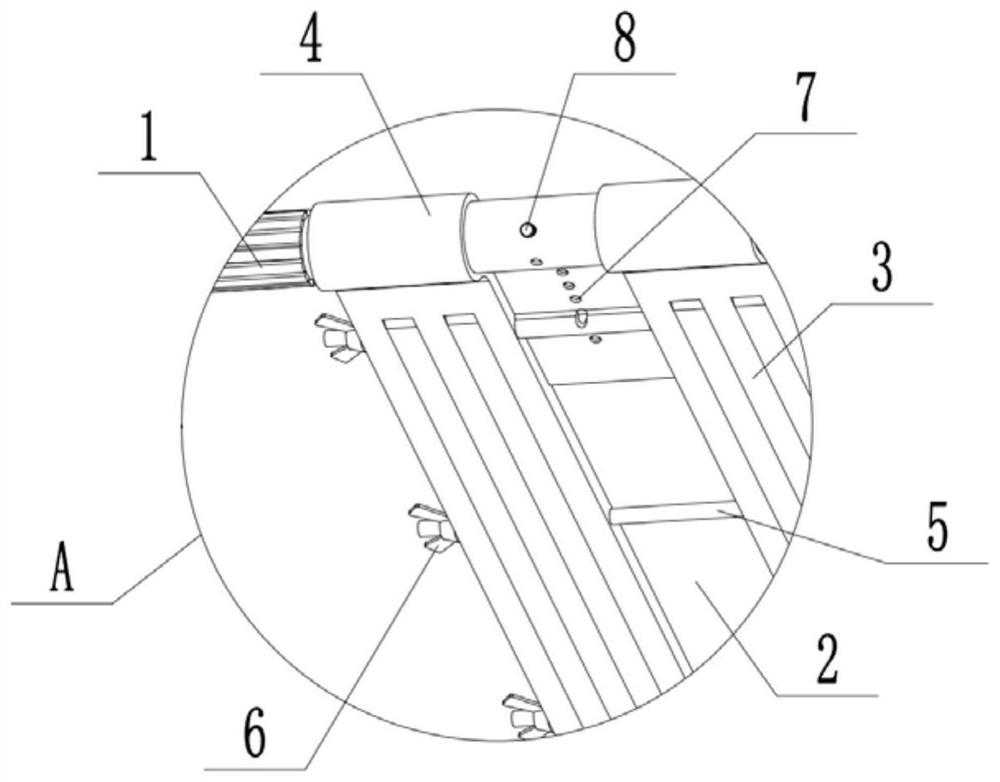

[0042] Embodiment 1 is basically as attached figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown: Multifunctional stretcher, including two bearing rods 1 arranged in parallel in the left and right directions, a plurality of supports are connected between the two bearing rods 1, and a plurality of detachable connection blocks 2, the blocking cloth 2 and the supporting piece are connected Staggered arrangement along the length of the bearing bar 1, in order to facilitate the medical staff to stably grasp the bearing bar 1, there are anti-skid parts at both ends of the bearing bar 1. In this embodiment, the anti-slip parts include a 1 Anti-slip thread on outer wall of end.

[0043] combine figure 1 and Figure 5 As shown, the support includes two support plates 3 of the same shape and size, the two support plates 3 are located between the two bearing rods 1 and the two support plates 3 are welded with a sleeve 4 at one end of the two support plates 3 close to th...

Embodiment 2

[0052] The difference between the second embodiment and the first embodiment is: as Image 6 As shown, in this embodiment, a blocking frame 9 is provided above the bearing rod 1. The blocking frame 9 includes a cross rod 901 and an insertion rod 902 welded to both ends of the horizontal rod 901. The top of the bearing rod 1 near both ends is open. There are blind holes arranged vertically downward, and the distance between the two blind holes is equal to the distance between the two insertion rods 902 on the blocking frame 9, so that the insertion rods 902 can be inserted into the sockets. In this embodiment, the locking rod 5 and the placement hole in the first embodiment are clamped between the insertion rod 902 and the blind hole to prevent the insertion rod 902 from being easily pulled upwards after being inserted into the blind hole.

[0053]In this embodiment, a cross bar 901 is arranged above the bearing bar 1, and the shielding effect of the cross bar 901 is used to pr...

Embodiment 3

[0055] The difference between the third embodiment and the second embodiment is: as Figure 8 As shown, the sleeve 4 has a first through hole 10 and a second through hole 11. When the two support plates 3 in the same support are rotated to the same plane, the first through hole 10 is aligned with the blind hole, so that the insertion When the rod 902 is inserted into the blind hole, it also passes through the first through hole 10; when the two support plates 3 in the same support are rotated to Figure 7 In the cross state, the second through hole 11 is aligned with the blind hole, so that the insertion rod 902 also passes through the second through hole 11 when inserted into the blind hole.

[0056] In this embodiment, by arranging the first through hole 10 and the second through hole 11 on the sleeve 4, when the two support plates 3 in the same support member are rotated to the same plane or rotated to a crossed state, the insertion rod 902 When inserted into the blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com