Moving driving mechanism of sleeper grinding machine

A driving mechanism and grinding machine technology, which is applied to grinding driving devices, grinding frames, grinding machine parts, etc., can solve the problems of low machining accuracy, high labor cost, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

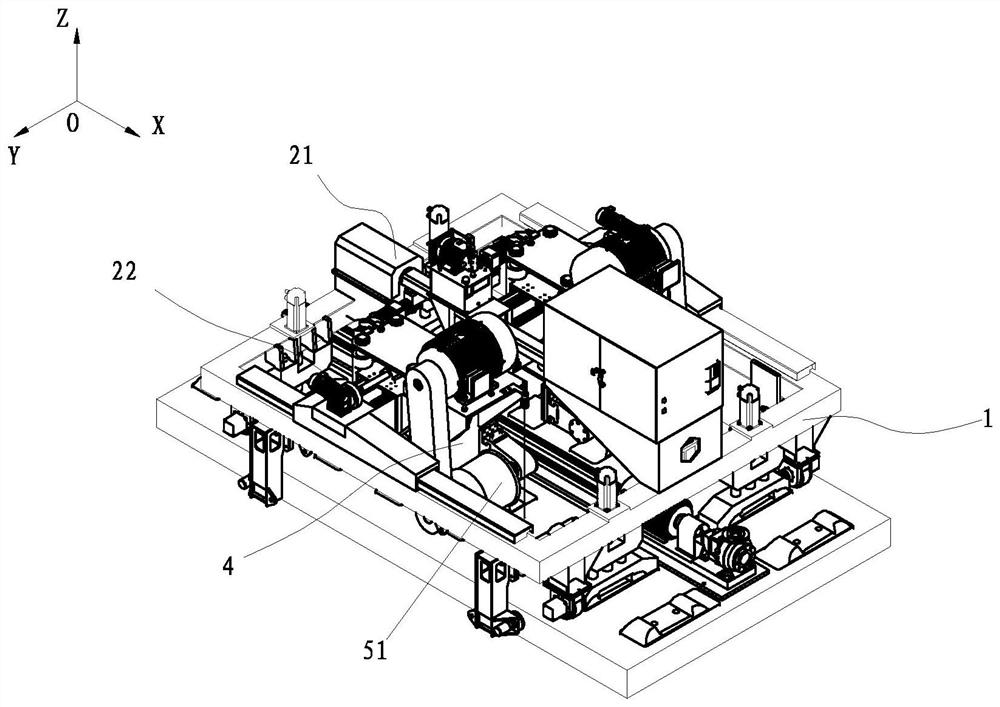

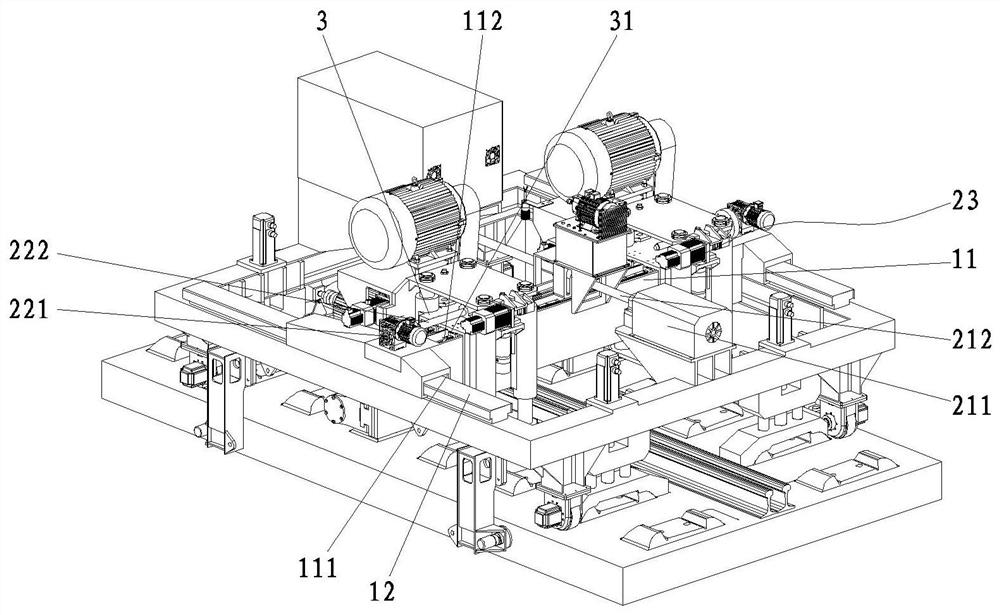

[0044] In the figure, the coordinate axes X, Y, and Z respectively represent the front-to-back direction, the left-right direction and the up-down direction of the present invention, and the coordinate axis X points to the front direction, the coordinate axis Y points to the right direction, the coordinate axis Z points to the upward direction, and the coordinate axes X, Y The intersection point of , Z is point O.

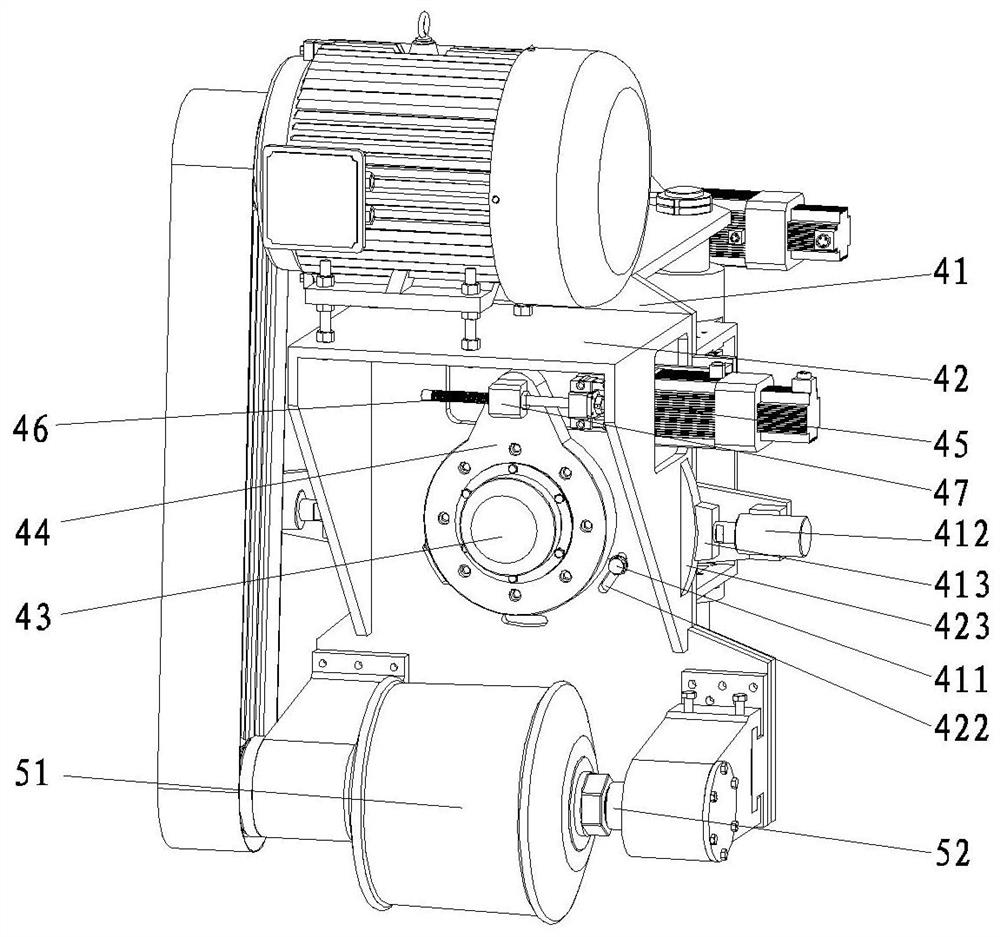

[0045] like Figure 1-5As shown, a sleeper grinding machine 5 mobile driving mechanism, including a frame 1, is characterized in that it includes a moving beam 11 and a first power device 21 that drives the moving beam 11 to move along the front and rear direction of the frame 1, and the moving beam The two ends of the beam 11 are respectively slidingly connected to the left and right sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com