All-area multi-module intelligent safflower harvesting robot and control method thereof

A robot and multi-module technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of limiting the harvesting efficiency of safflower, rough cutting methods, and low cleaning rate of filaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0151] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

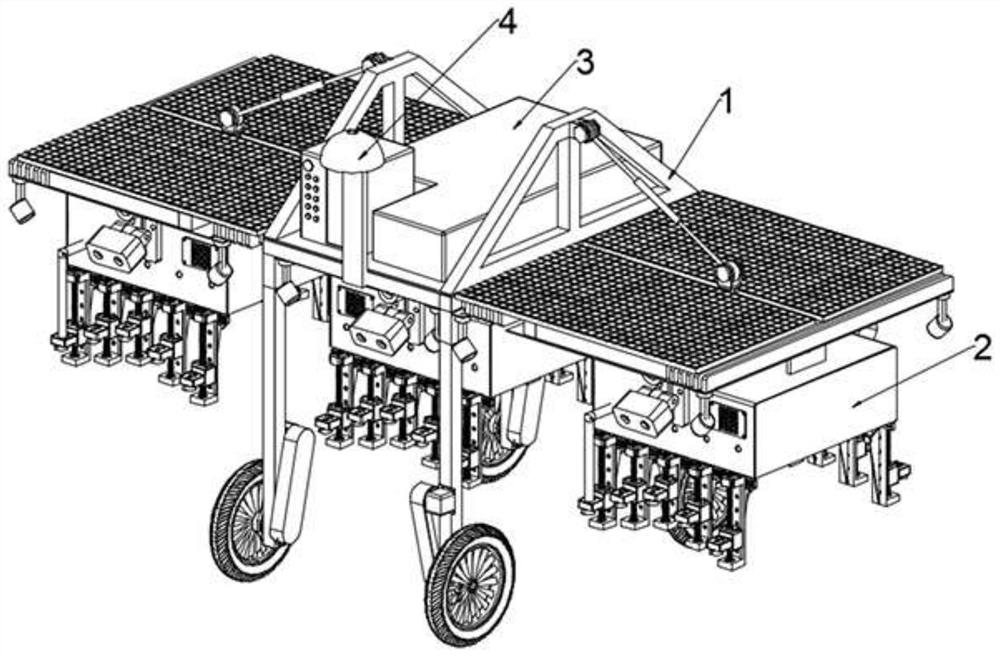

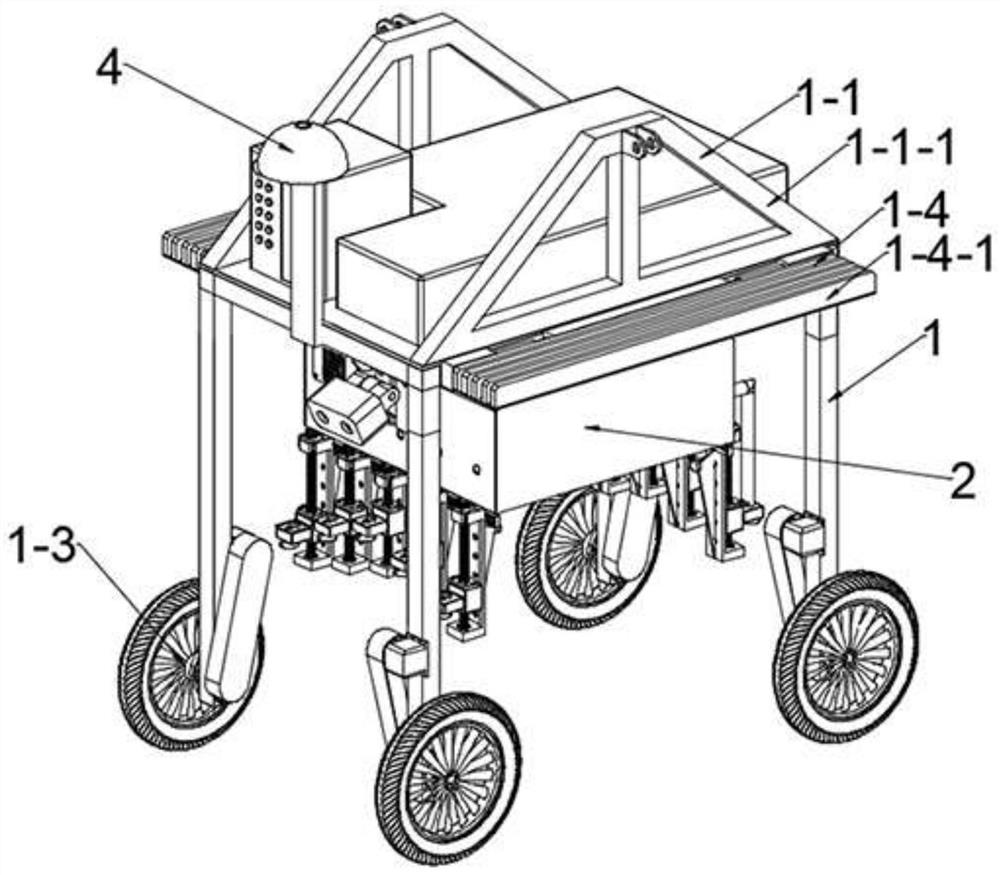

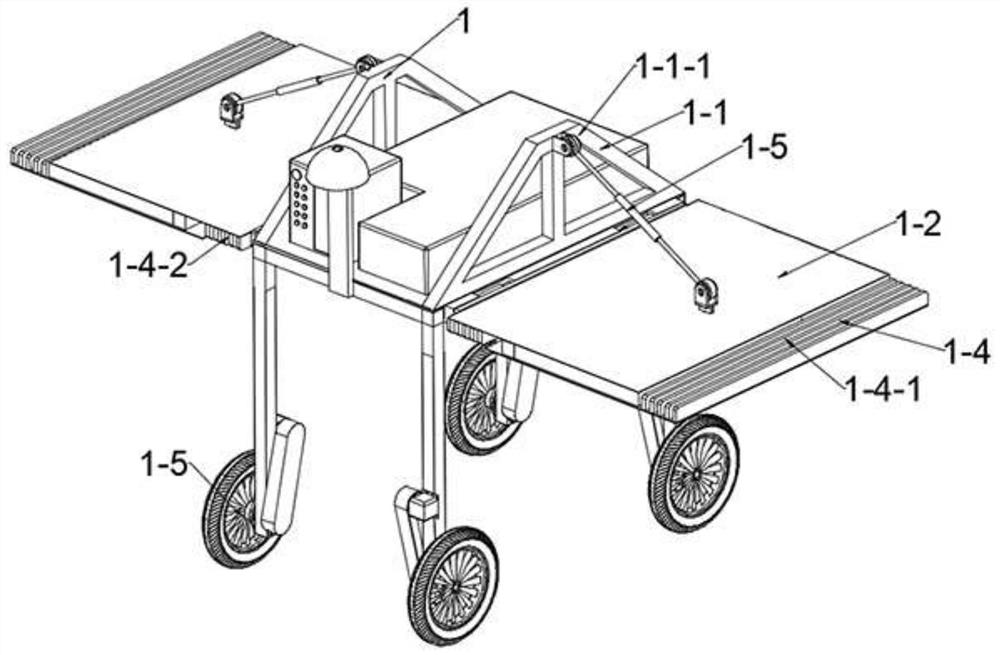

[0152] Such as figure 1 , figure 2 , image 3 As shown, a safflower global multi-module intelligent harvesting robot includes a frame 1, a global safflower harvesting module 2, an auxiliary module 3 and a control system 4; the frame 1 includes a main frame 1-1, a module expansion Frame 1-2, walking wheel set 1-3, expansion frame mounting rail 1-4 and leveling telescopic rod 1-5; four described walking wheel sets 1-3 are fixedly connected to the main frame 1-14 respectively end of a supporting leg.

[0153] The steering of the harvesting robot can be realized by the differential rotation of the four traveling wheel sets 1-3.

[0154] The expansion frame installation rail 1-4 includes the expansion frame installation A rail 1-4-1 and the expansion frame installation B rail 1-4-2; the left and right sides of the main frame 1-1 are symmetrically instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com