Gear device and manufacturing method for gear device

A technology of a gear device and a manufacturing method, which is applied to a gear transmission device, a hoisting device, a transmission device, etc., can solve the problems such as the decline of the rotation accuracy, and achieve the effect of suppressing the decline of the rotation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

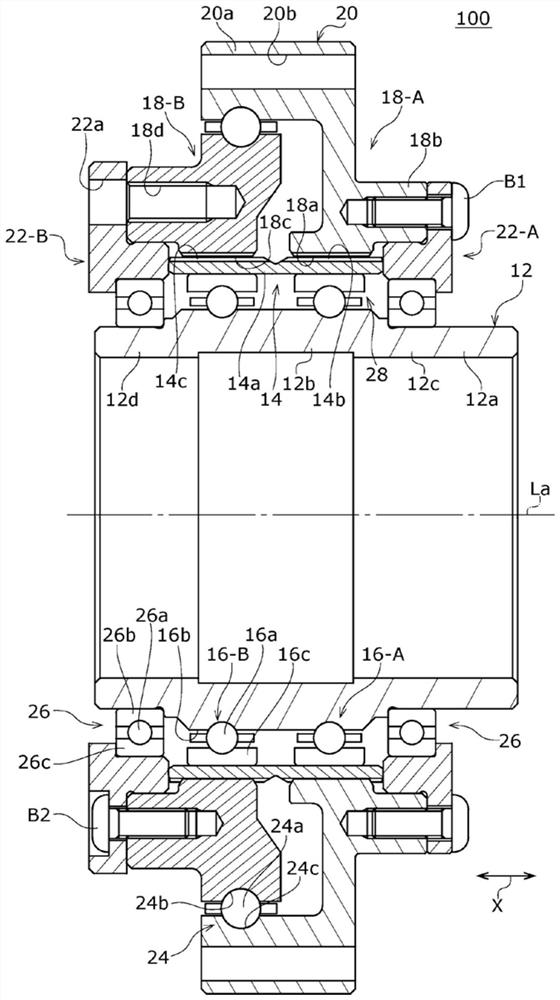

[0023] First, the overall configuration of the gear device 100 according to the first embodiment will be described. figure 1 It is a side sectional view showing the gear device 100 of the first embodiment. The gear device 100 is a flexural engagement type gear device that flexibly deforms the external gear 14 meshing with the internal gears 18 -A, 18 -B and rotates the external gear 14 to output its rotation component. The gear device of the present embodiment is a so-called cylindrical flexural meshing gear device that decelerates the rotation of the vibrating body 12 by using the deceleration internal gear 18-A and the output internal gear 18-B to output the output.

[0024] The gear device 100 mainly includes: a vibrating body 12; an external gear 14; vibrating body bearings 16-A, 16-B; internal gears 18-A, 18-B; supporting components 20; and bearing housings 22-A, 22 -B. Hereinafter, the direction along the rotation centerline of the vibrating body 12 may be simply refer...

no. 2 Embodiment approach

[0060] Next, a gear device 100 according to a second embodiment of the present invention will be described. In the drawings and description of the second embodiment, the same or equivalent components and components as those of the first embodiment are given the same reference numerals. Descriptions of overlapping contents with those of the first embodiment are appropriately omitted.

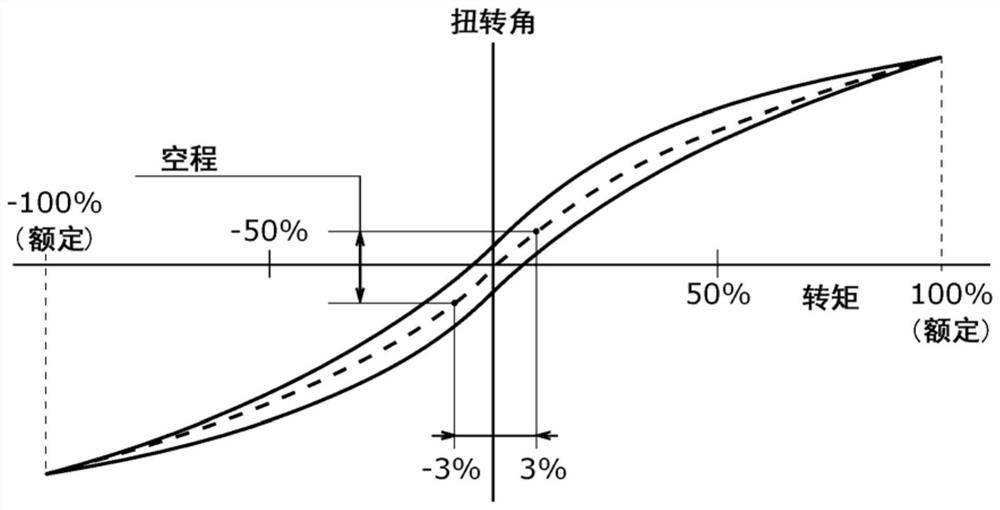

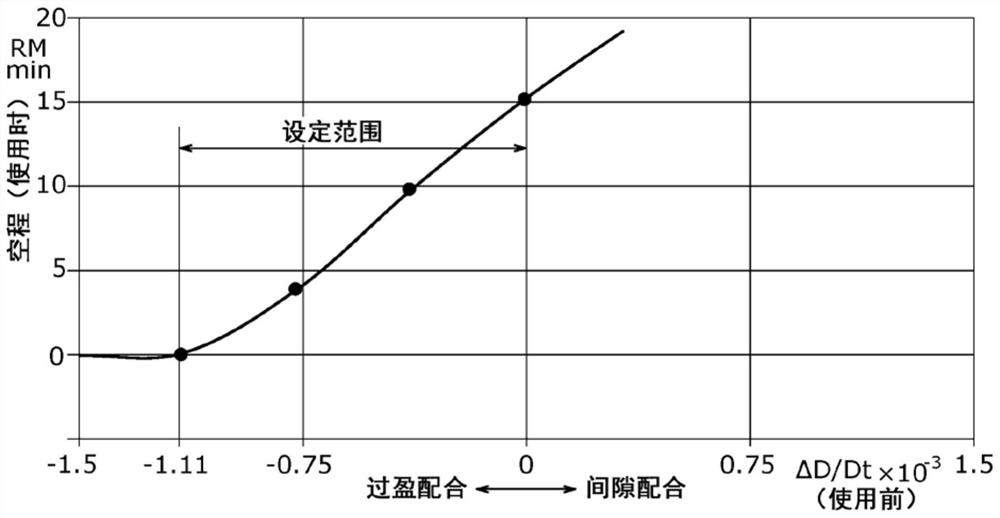

[0061] The gear device 100 of the present embodiment includes an internal gear 18 and an external gear 14 meshing with the internal gear 18, wherein the internal gear 18 is made of resin, and the external gear 14 is made of a material having a coefficient of linear expansion smaller than that of the resin. , and the PCD of the external gear 14 in the state where the temperature of the gear device 100 is 20°C is set to be larger than the PCD of the internal gear 18 so that when the temperature of the gear device 100 is in the range of 40°C to 50°C The idle time is not less than 0 min and not more...

no. 3 Embodiment approach

[0066] Next, the manufacturing method S200 of the gear device according to the third embodiment of the present invention will be described. In the drawings and description of the third embodiment, the same or equivalent components and components as those of the first embodiment are given the same reference numerals. Descriptions of overlapping contents with those of the first embodiment are appropriately omitted. The manufacturing method S200 of the present embodiment is a method of manufacturing the aforementioned gear device 100 , and includes an embedding step of embedding the external gear 14 into the internal gear 18 in an interference fit manner.

[0067] According to this aspect, since the external gear 14 is fitted into the internal gear 18 with an interference fit, even if thermal expansion occurs during use, the lost motion can be suppressed to be small.

[0068] In the above-mentioned embedding step, the internal gear 18 may be heated and then embedding may be perf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap