Combined metal cutting machine tool spindle

A metal cutting, machine tool spindle technology, applied in metal processing mechanical parts, metal processing equipment, large fixed members, etc., can solve the problems of reduced spindle rotation accuracy, reduced pre-pressure, large cutting force, etc., to avoid the decline of rotation accuracy. , to avoid the disappearance of pre-pressure and improve the effect of rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

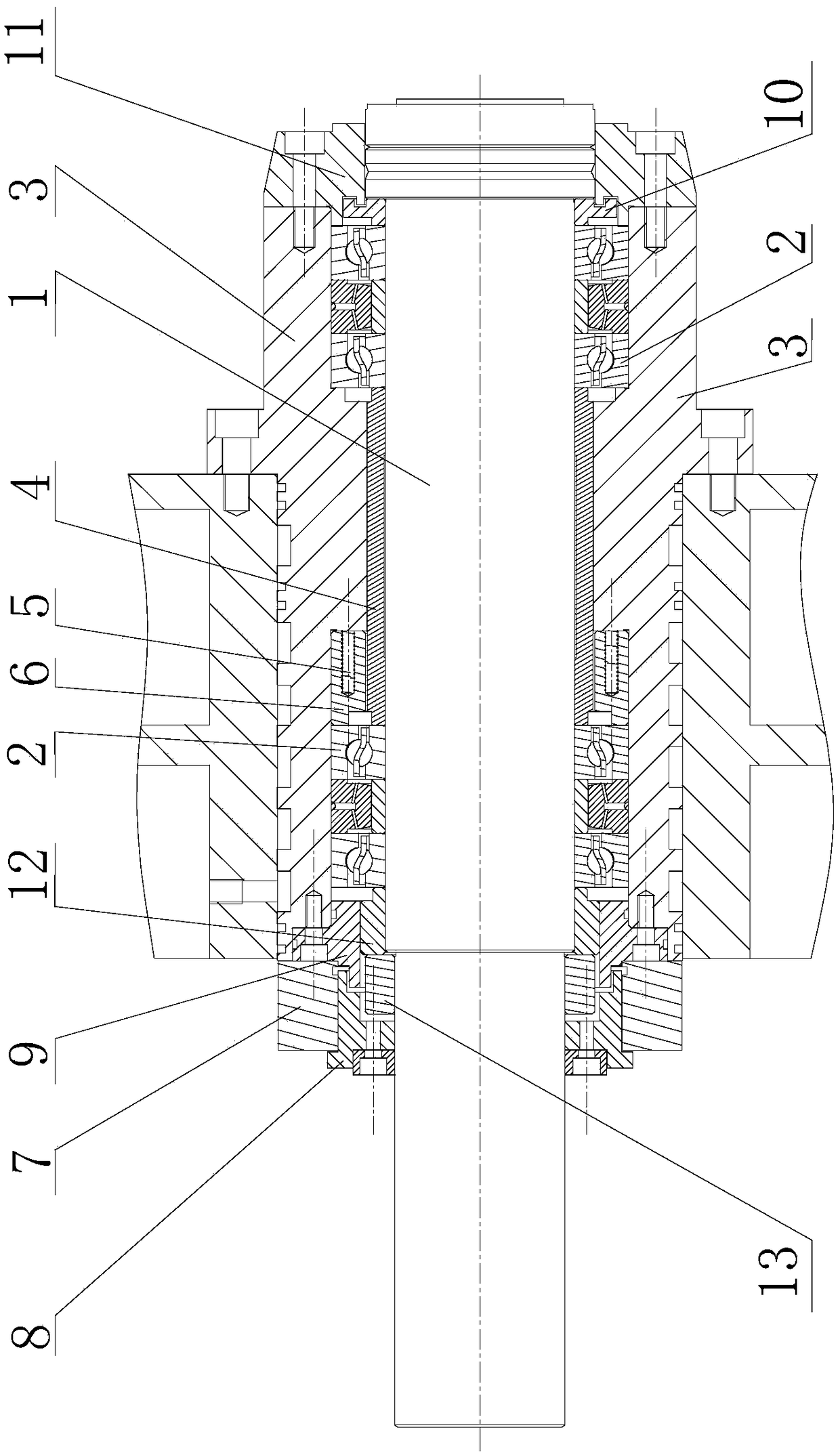

[0017] refer to figure 1 , a composite metal cutting machine tool spindle of the present invention, comprising a spindle 1, a bearing 2, a shaft body 3 and a spacer ring 4 matched and connected with the bearing 2, the bearing 2 is closely connected with the spindle 1 and the outside is covered by the shaft body 3 covering, the outer ring of the bearing 2 is connected with an elastic workpiece 5 for generating elastic preload, and the elastic workpiece 5 is arranged outside the spacer 4, and the spacer 4 is arranged between the main shaft 1 and the shaft body 3 between.

[0018] Specifically, the shaft body 3 cooperates with the shaft body 1 to implement rigid preload on the bearing 2, and the spacer ring 4 can keep the shaft body 1 compact to a certain degree, and being arranged between the shaft body 1 and the shaft body 3 can improve its stability;

[0019] Preferably, the elastic workpiece 5 is a spring, which can provide good elastic pressure, specifically a helical sprin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap