Split-type broken soil deep scarification machine capable of realizing individual regulation

A technology of individually adjustable subsoilers, applied to agricultural machinery and implements, shovels, plows, etc., which can solve problems such as large clods, uneven ground surfaces, and debris blockages in front of the shovel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

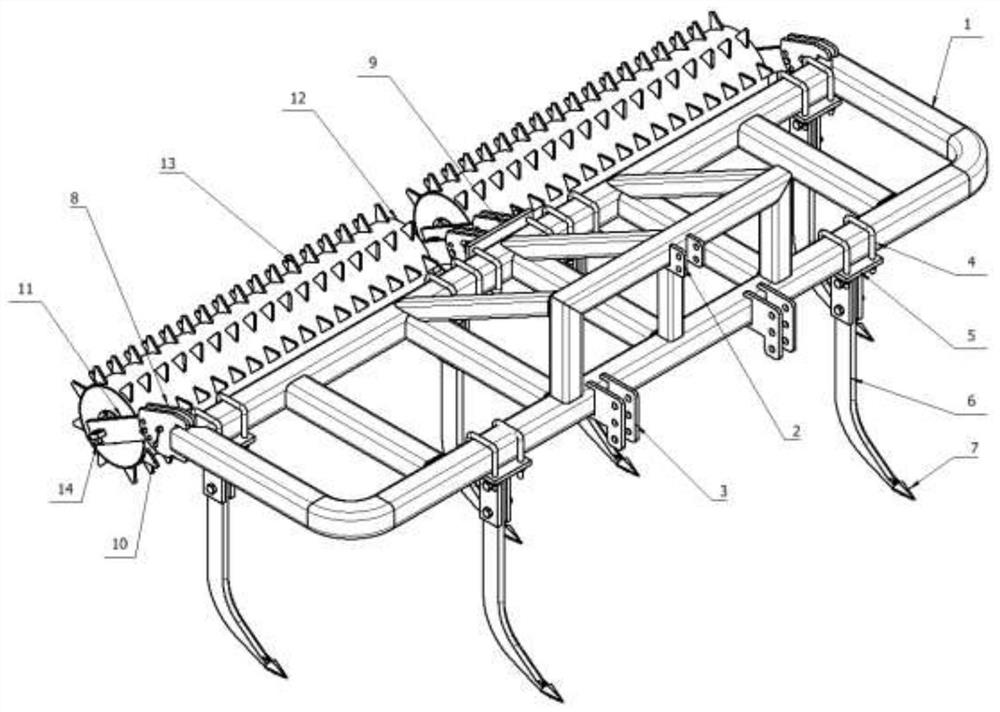

[0010] Such as figure 1 Shown, the present invention 1. frame, 2. upper suspension, 3. lower suspension, 4. U type clip, 5. subsoiling shovel splint welding, 6. subsoiling shovel bar, 7. subsoiling shovel point, 8 .The outer connecting plate of the breaking wheel, 9. The inner connecting frame of the breaking wheel, 10. Pin 1, 11. The support plate of the breaking wheel, 12. The part of the breaking wheel, 13. The tip of the breaking wheel, 14. The pin 2. The work can be completed by driving the tractor.

[0011] The above technical features constitute the best embodiment of the present invention, which has strong adaptability and implementation effect, and non-essential technical features can be increased or decreased according to actual needs to meet the needs of different situations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com