Motor rotor sheet high-precision laminating device

A rotor punching, high-precision technology, applied in the field of high-precision stacking equipment for motor rotor punching, can solve problems such as low punching efficiency and affecting rotor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The application will be described in further detail below in conjunction with the accompanying drawings.

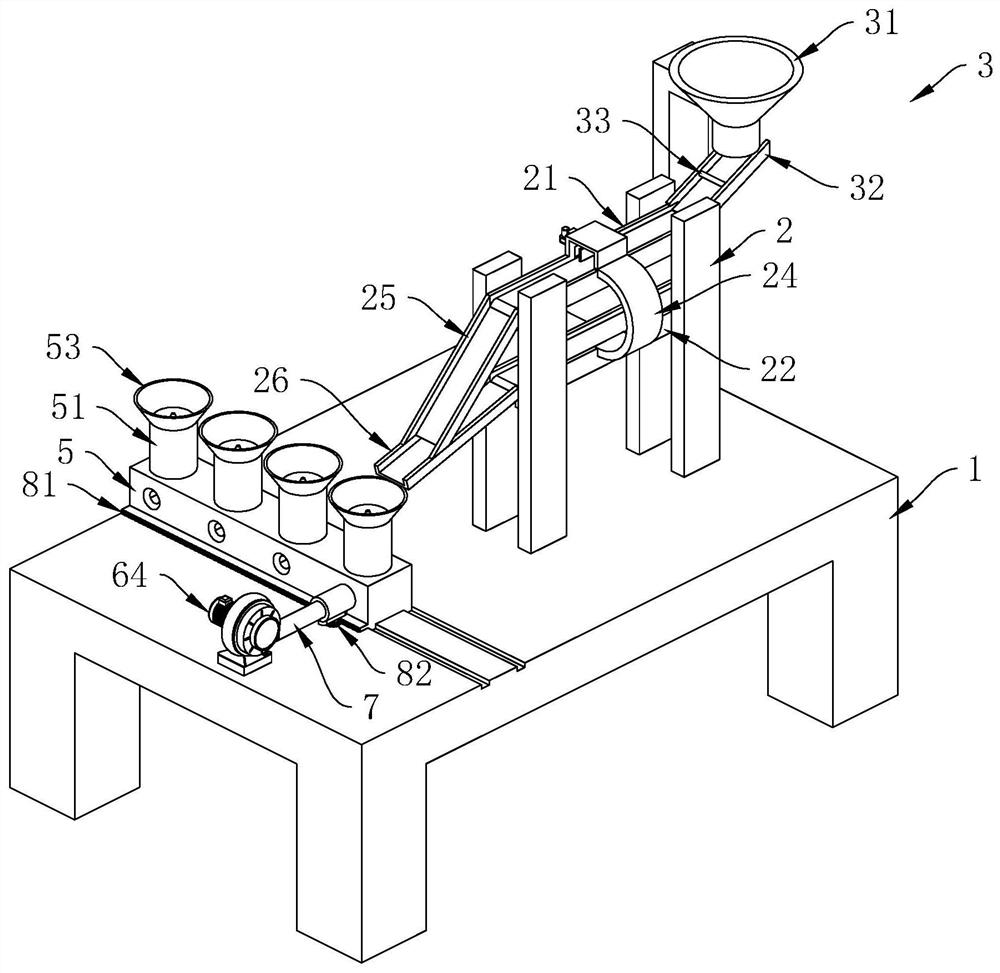

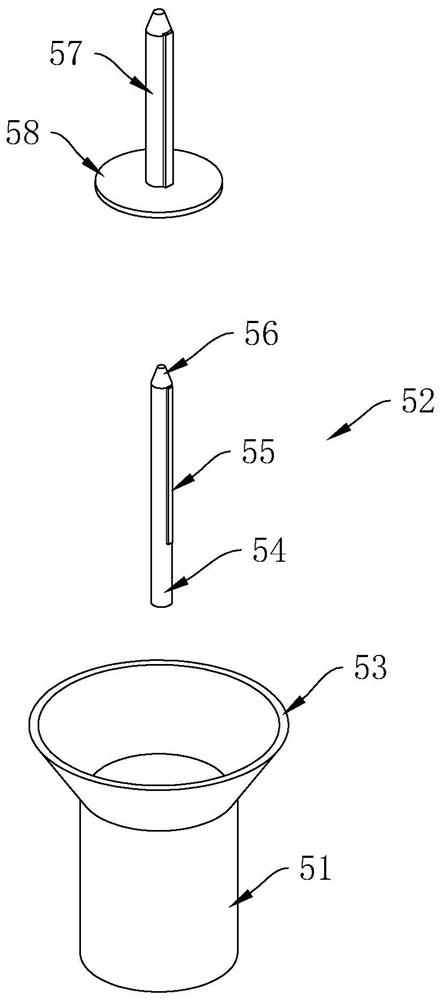

[0037] Such as figure 1 As shown, a high-precision stacking equipment for punching motor rotors includes a base 1, and a double-layer support frame 2 is arranged on one end of the base 1 . A first conveyor belt 21 and a second conveyor belt 22 are arranged horizontally on the upper layer and the lower layer of the support frame 2 respectively, and a feeding mechanism 3 is arranged at the starting end of the first conveyor belt 21 .

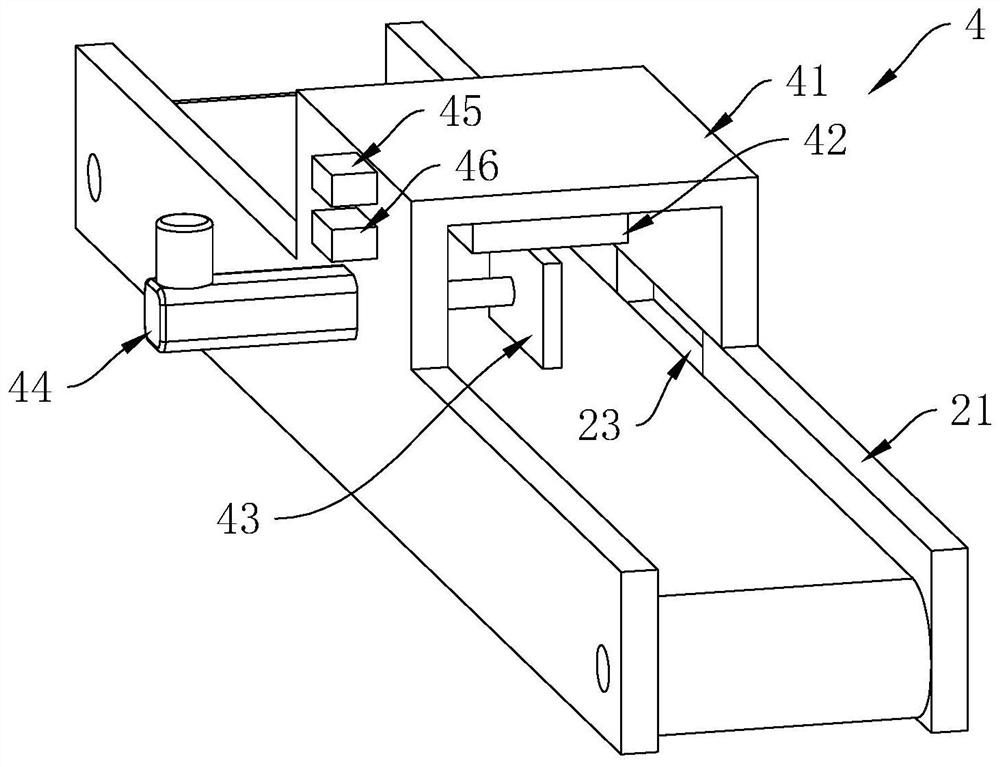

[0038] Such as figure 1 , figure 2 As shown, one side of the middle position of the first conveyor belt 21 and the second conveyor belt 22 is provided with a gap 23, and a semicircular connecting channel 24 is arranged between a pair of gaps 23, and a pair of rotors are arranged on the first conveyor belt 21. Sorting mechanism 4 for punching and detecting and sorting.

[0039] When the above-mentioned stacking equipment is used, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com