A kind of installation method of roller cleaning device

A technology of cleaning device and installation method, applied in the field of construction machinery, can solve the problems of high abrasion speed, short service life and high replacement frequency of the scraper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

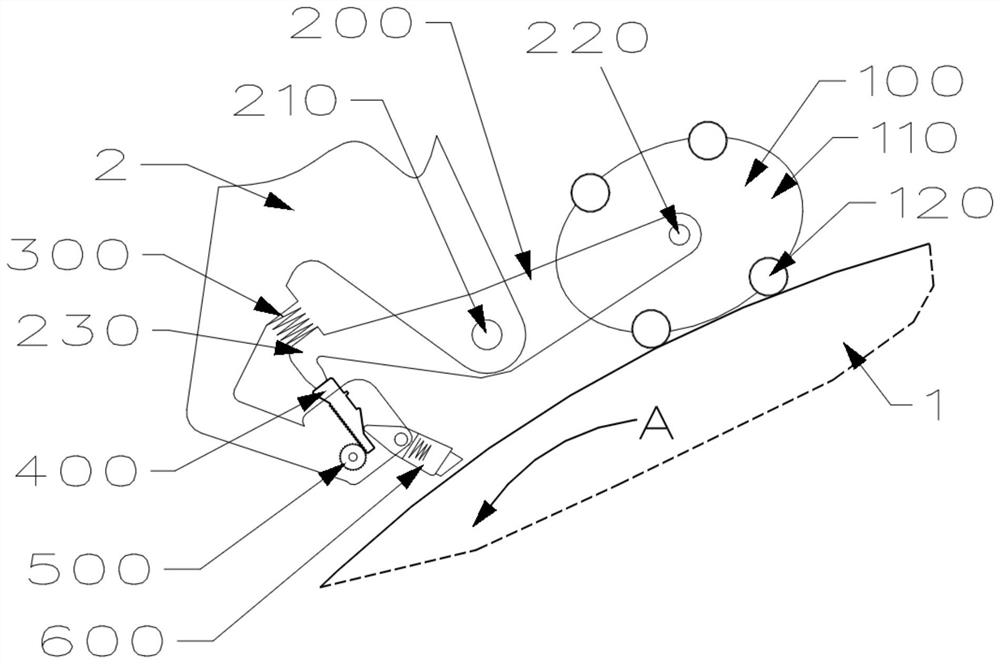

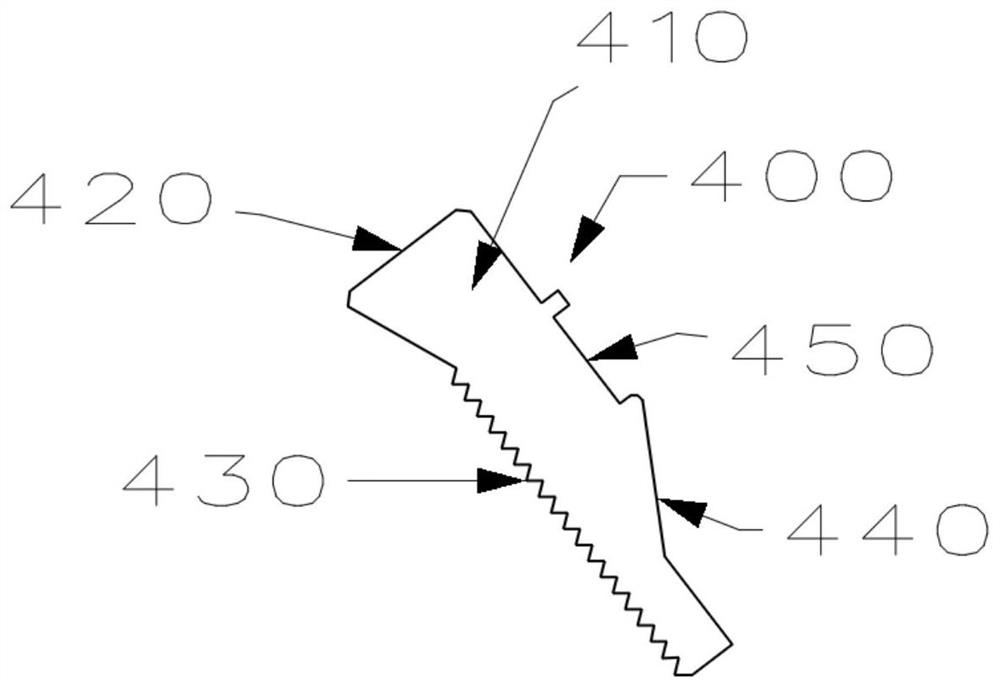

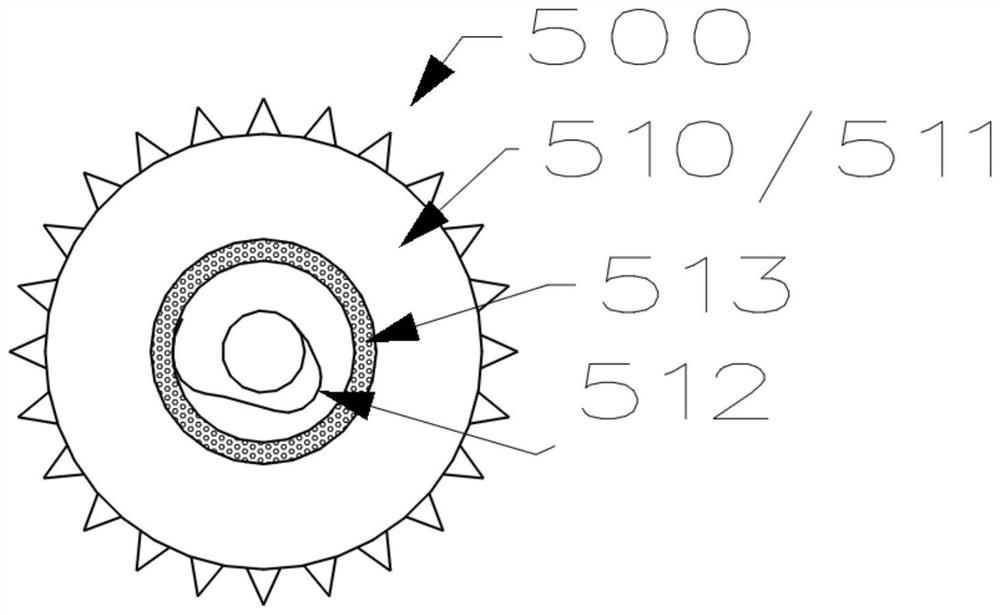

[0085] Such as figure 1 As shown, the supporting roller cleaning device of the present application includes a pilot wheel 100 , a floating lever 200 , a floating lever applying force assembly 300 , a trigger lever 400 , a trigger lever delay reset assembly 500 and a shovel assembly 600 .

[0086] The pilot wheel 100 plays a role in driving the floating lever 20 to rotate around its fulcrum after touching the sticky debris on the pressure roller 1; the pilot wheel 100 includes a pilot wheel main body 110 and a foundation wheel; the main body 110 of the pilot wheel is elliptical, and the midpoint position (center position, center of gravity) of the line connecting the two foci of the ellipse is rotatably and fixedly connected with one end of the floating lever 200; the basic wheel 120 It is rotatably and fixedly connected to the main body 110 of the pilot wheel, and the number of the basic wheels 120 is four, and the four basic wheels 120 are symmetrically arranged in pairs; Th...

Embodiment 2

[0104] Considering that during the operation of the supporting roller cleaning assembly of the application, the wear of the scraping plate 620 (in the process of compensating the wear of the scraping plate 620 by the elastic body 630 extending from the scraping plate) will cause the continuous pressure of the scraping plate on the pressure roller 1 surface. reduce, and then affect the cleaning effect of the shovel plate 620 on sundries (initially the pressure is relatively large, and the cleaning effect is good but the shovel plate 620 wears quickly, and then the pressure gradually decreases, and the cleaning effect becomes worse); for this reason, the present embodiment On the basis of the above-mentioned embodiments, an elastic body elastic force adjusting device 631 is added to reduce the wear speed of the blade 620 at the initial stage of use by adjusting the compressed amount of the elastic body 630 protruding from the blade, while ensuring the cleaning effect. Such as F...

Embodiment 3

[0110] During the actual application of the present application, it was found that the possibility of sticking materials in different areas on the pressure roller 1 is different, which in turn leads to different degrees of wear of the shovel plate 620 in different areas. Sometimes a shovel plate 620 is partially worn too severely and the entire shovel plate 620 needs to be replaced .

[0111] Such as Figure 5 As shown, in view of the above problems, this embodiment divides the entire pressure roller into multiple pressure roller partitions 11 and modularizes the shovel plate 620, and each pressure roller partition 11 corresponds to one shovel plate 620; when it is necessary to replace the shovel plate, only replace the severely worn one. The shovel plate 620.

[0112] Simultaneously, the steps in the second embodiment of the present application are optimized, and step 5 in the optimized embodiment two is:

[0113]The blade casing 610 of the blade assembly 600 is rotatably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com