Continuous welding device for mask ear loops and mask production line

A welding device and ear strap technology, applied in clothing, apparel, household components, etc., can solve problems such as reducing the production efficiency of masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

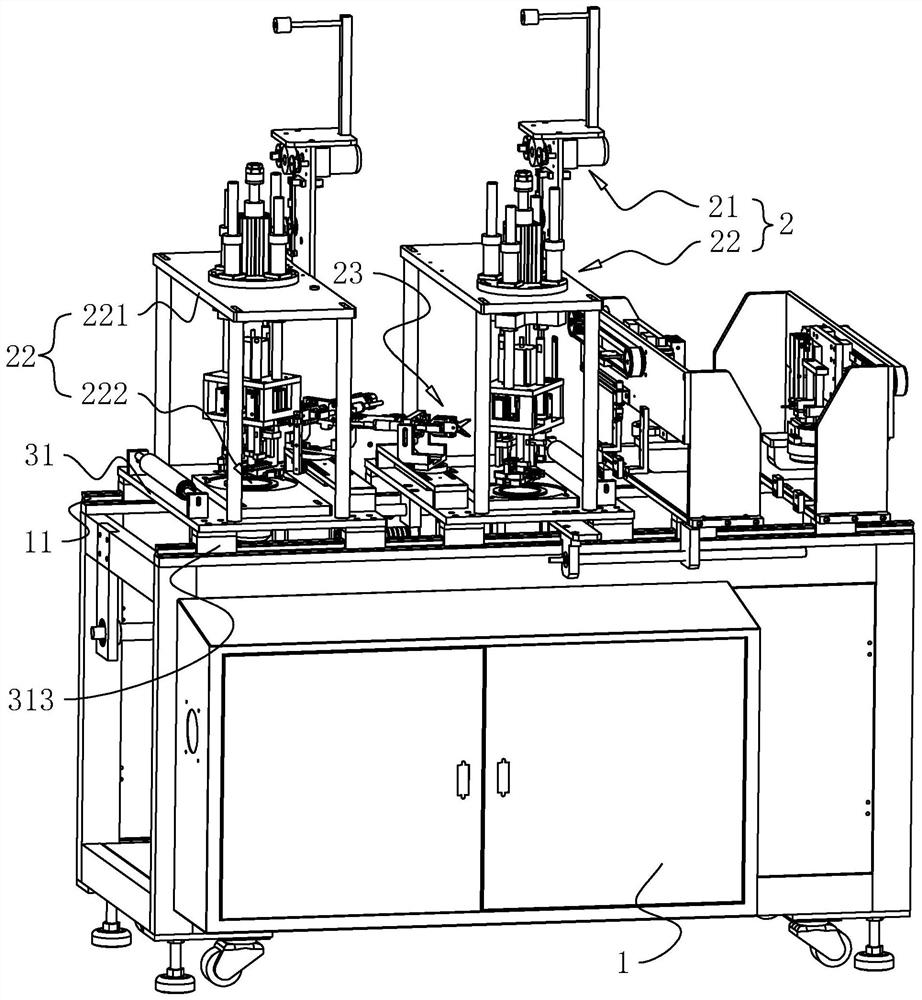

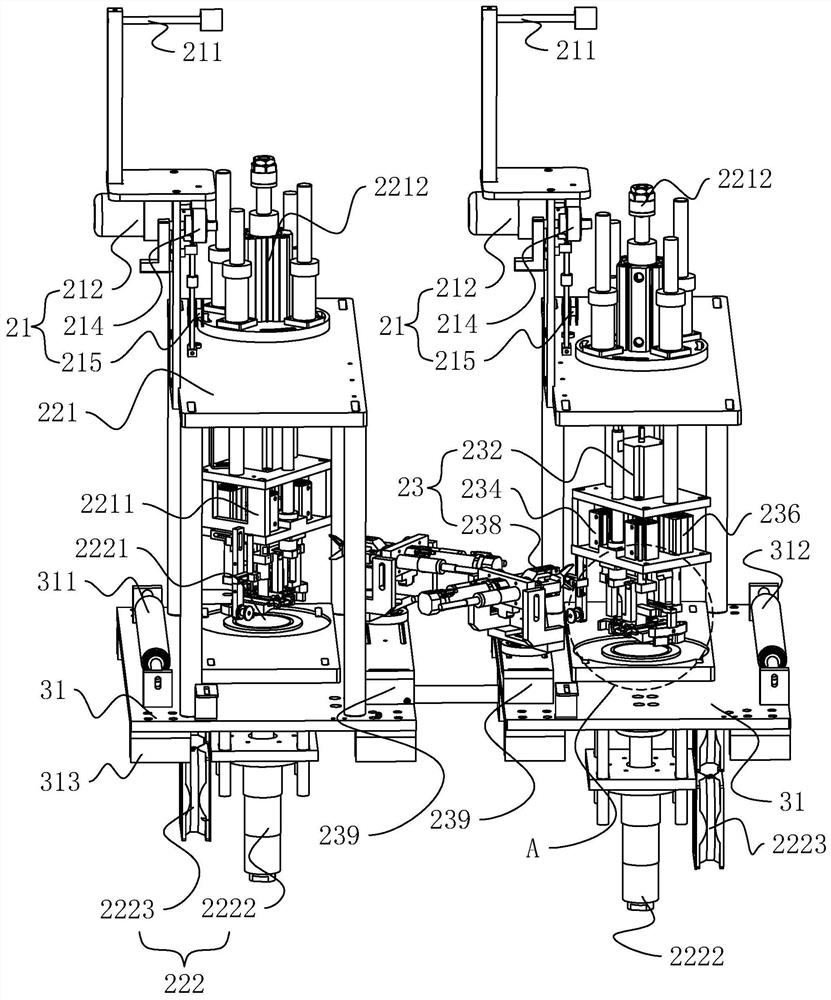

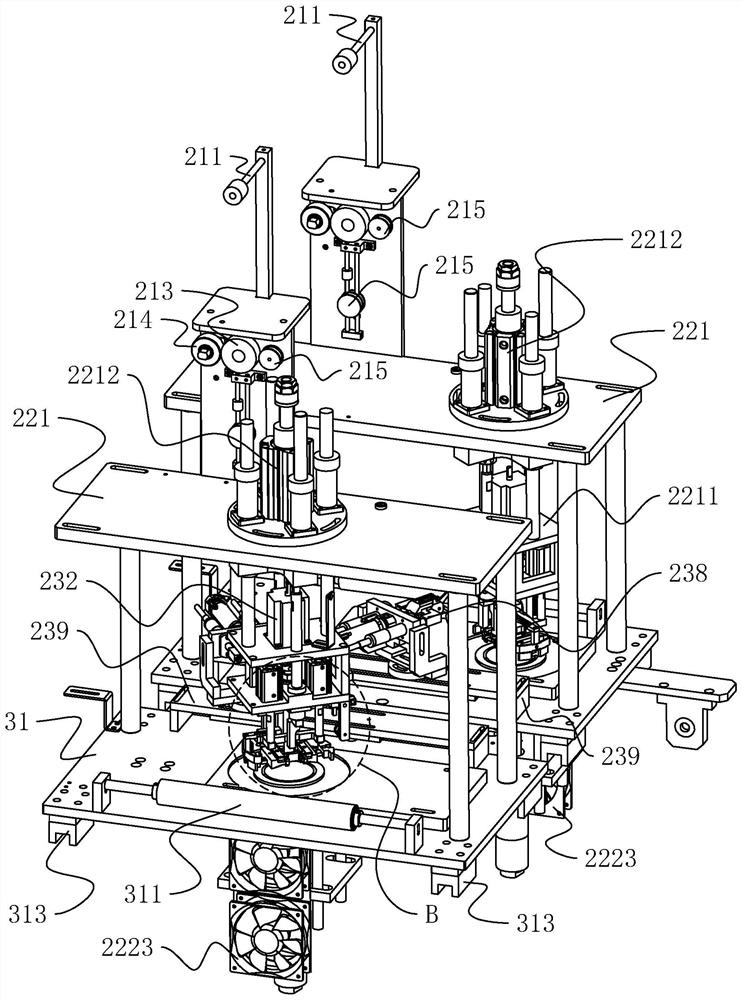

[0045] refer to figure 1 , The mask earband continuous welding device includes a frame 1, an earband installation mechanism 2 and a follower mechanism that reciprocates along the mask conveying direction, and the mask is conveyed along the length direction of the frame 1. In order to ensure that the mask does not stop feeding during the installation of the ear straps, the following mechanism includes a following mounting plate 31 for installing the ear strap mounting mechanism 2 and a drive assembly 32 that drives the following mounting plate 31 to move. The driving assembly 32 is used to drive the following mounting plate 31 moves synchronously with the mask during the earband welding process, so that the transmission of the mask does not need to be stopped during the earband welding, and the production efficiency of the mask is improved.

[0046] refer to figure 1 , in order to improve the stability of following the movement of the mounting plate 31, a guide rail 11 is prov...

Embodiment 2

[0061] refer to Figure 7 The difference between this embodiment and Embodiment 1 is that the driving assembly 32 includes a driving motor 321 fixedly arranged on the frame 1 and a driving gear 325 arranged at the output end of the driving motor 321, and the driving gear 325 corresponding to the frame 1 is rotated. There is a driven gear 326, and the driven gear 326 is coaxially fixed with an incomplete gear 327, and the corresponding incomplete gear 327 is fixed with the incomplete gear 327 following the installation plate 31. When meshing with the rack 328, the driving motor 321 drives and follows the mounting plate 31 to move synchronously with the mask. In this application, in order to improve the stability of the driving assembly 32 driving and following the movement of the mounting plate 31, the rack 328 is installed in the middle of the side of the following mounting plate 31 away from the mounting frame 221, and the length direction of the rack 328 is parallel to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com