Jelly cup blowing dropping device of jelly production line

A technology for jelly cups and production lines, which is used in packaging, transportation and packaging, conveyor objects, etc., can solve the problems of time-consuming and laborious, complicated installation structure, and difficult to clean up hidden dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

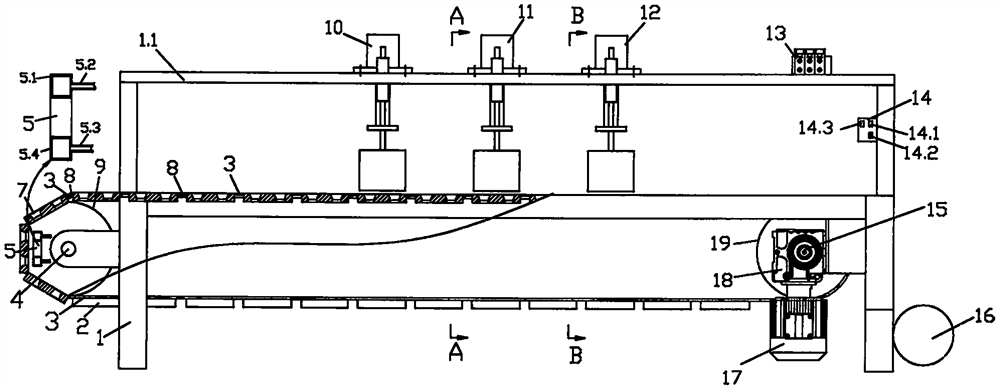

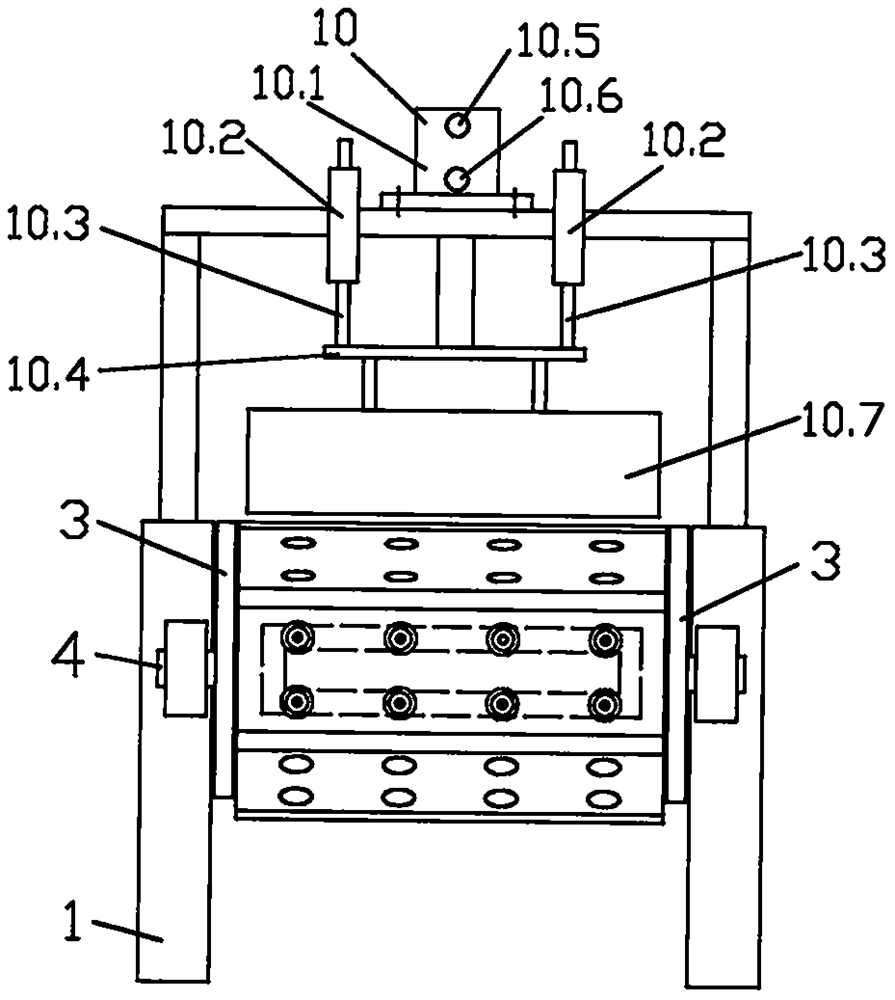

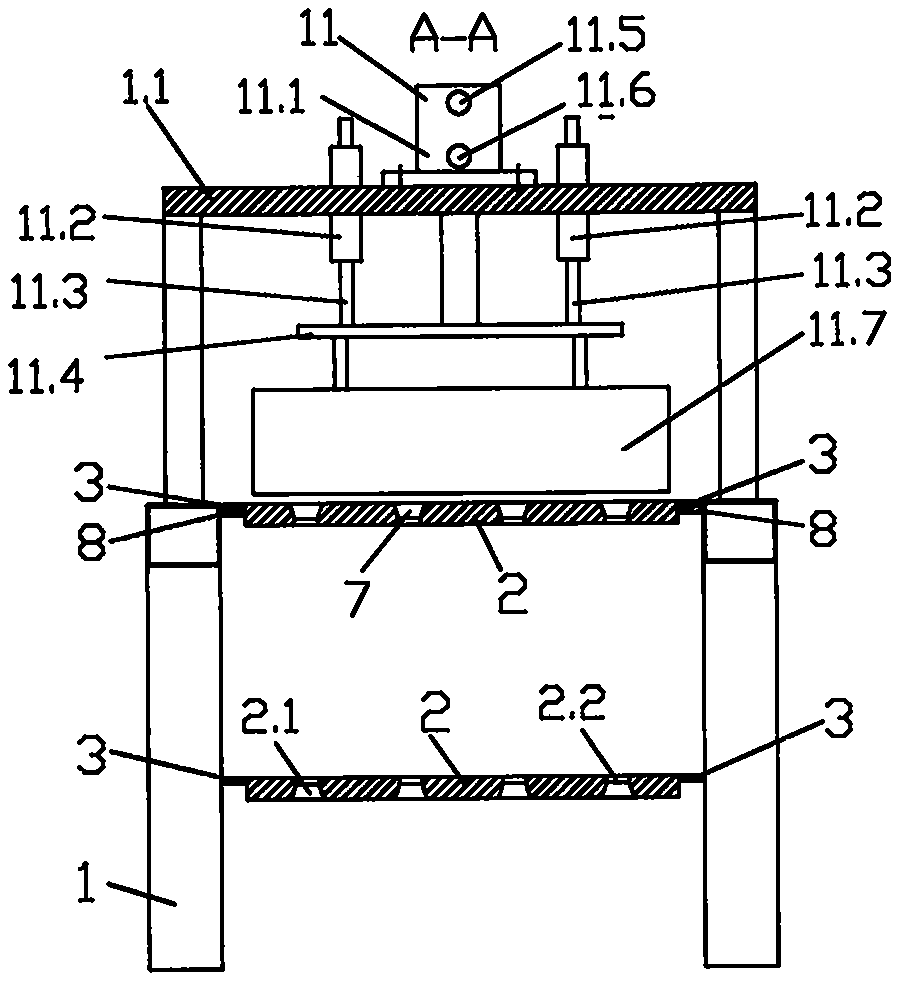

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] like Figure 1-Figure 6As shown, the jelly cup blowing and dropping device of the jelly production line includes a frame 1, and the front end of the frame 1 is fixedly connected to a reducer 18, and the reducer 18 is respectively connected to the motor 17 and the drive shaft 15, and the drive shaft 15 is fixedly connected to the drive shaft. Sprocket 19; the rear end of the frame 1 rotates to connect the driven shaft 4, and the driven shaft 4 is fixedly connected to the driven sprocket 9; the driving sprocket 19 and the driven sprocket 9 are connected by a chain 3 transmission; the frame 1 is provided with a chain Supporting plate 8, chain supporting plate 8 supporting chains; chain 3 is provided with jelly cup placement rack 2, jelly cup placement rack 2 is provided with jelly cup placement hole 2.1, jelly cup placement hole 2.1 places jelly cup 7, jelly cup pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com