Electronic connector moving mechanism

A technology of electronic connectors and moving mechanisms, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve the problems of inconsistent opening and closing actions of cylinders, increased device complexity, and many control steps of moving devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

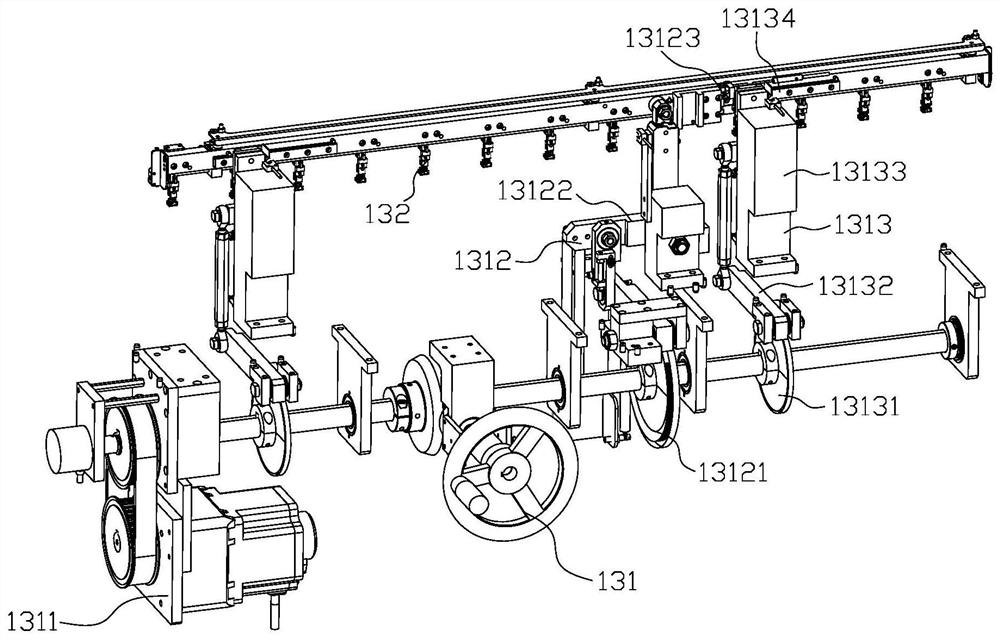

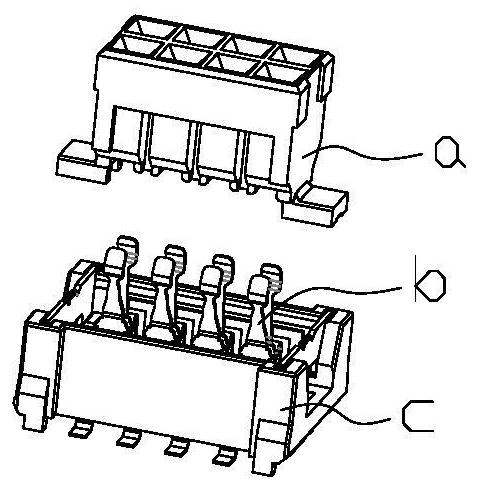

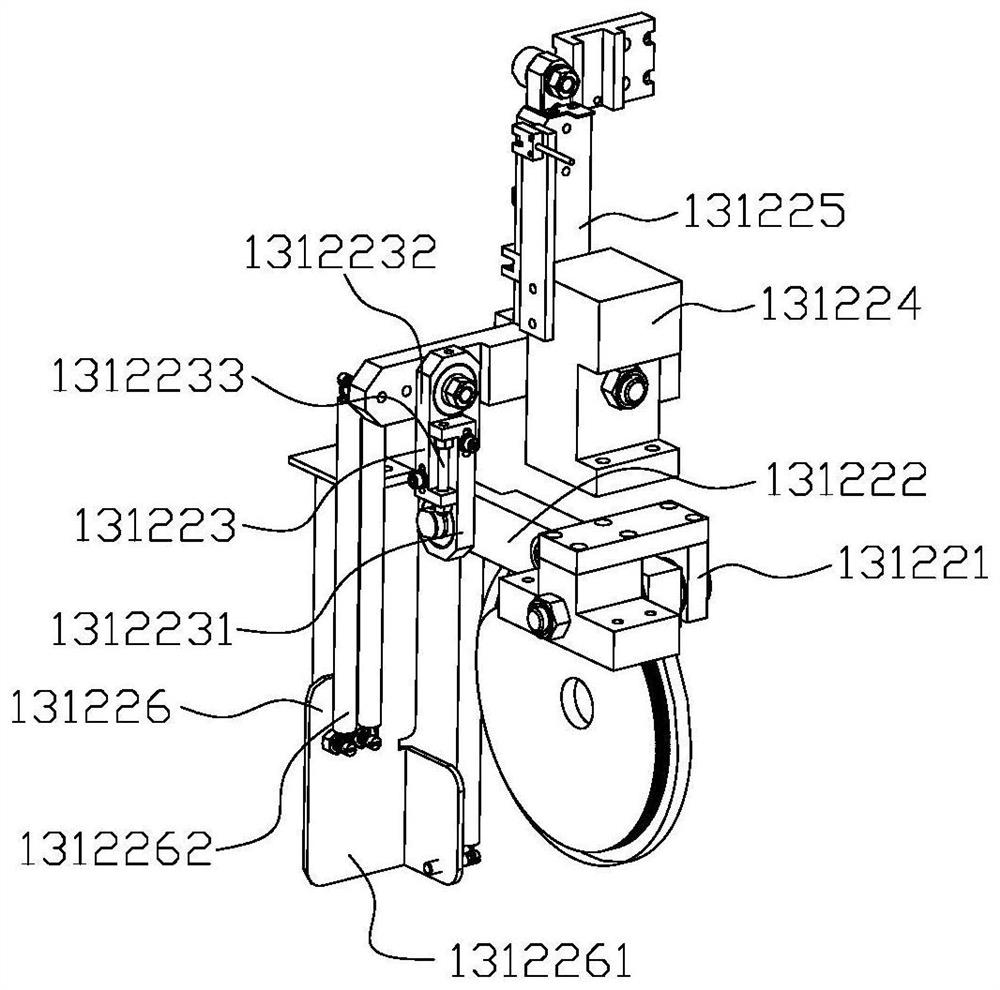

[0034] like figure 1 The shown connector moving device includes a connector moving mechanism 131 and a connector clamping mechanism 132; the connector moving mechanism 131 is fixed on the workbench, and the connector moving mechanism 131 is connected with the connector clamping mechanism 132 The connector clamping mechanism 132 is in contact with the electronic connector; the connector moving mechanism 131 is used to drive the connector clamping mechanism 132 to move circularly; the connector clamping mechanism 132 is used to clamp the electronic connector; the connector moving mechanism 131 It includes a moving drive assembly 1311, a left and right push assembly 1312, and an up and down push assembly 1313; the move drive assembly 1311 is fixed on the workbench; the output ends of the move drive assembly 1311 are respectively connected to the lower ends of the left and right push assemblies 1312 and a plurality of up and down push assemblies 1313; The upper ends of the left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com