Piezoelectric resonator, method for adjusting frequency thereof and communication apparatus comprising said resonator

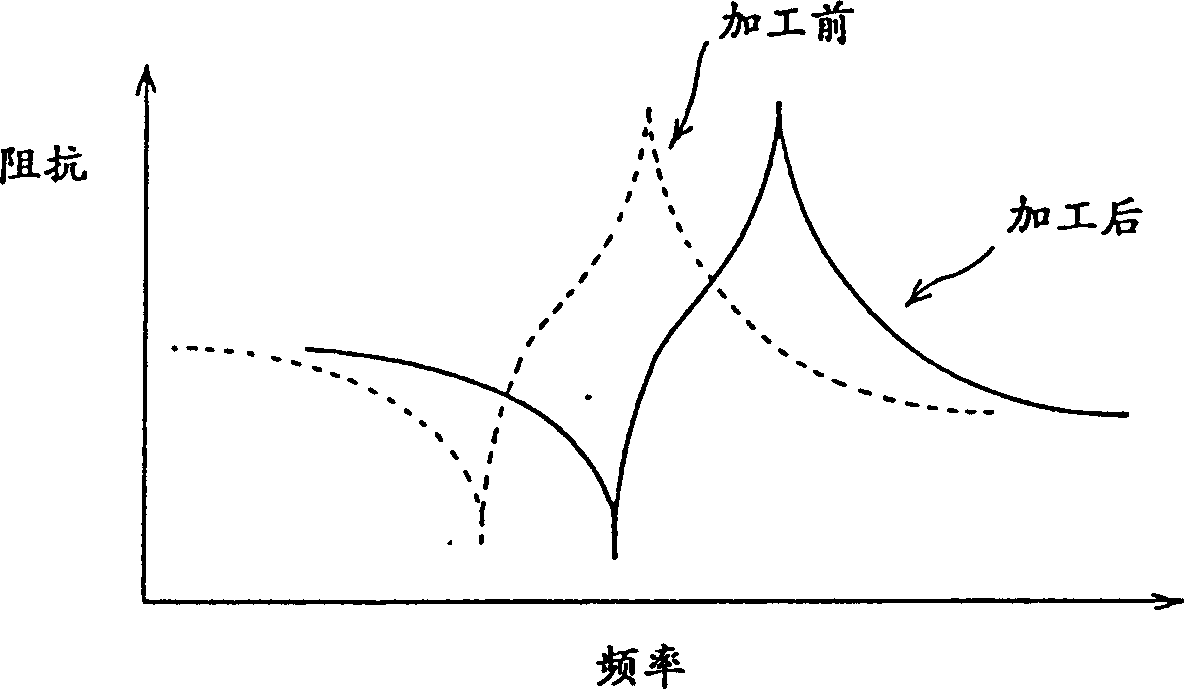

A piezoelectric resonator and resonant frequency technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve difficult applications, automation difficulties, performance changes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

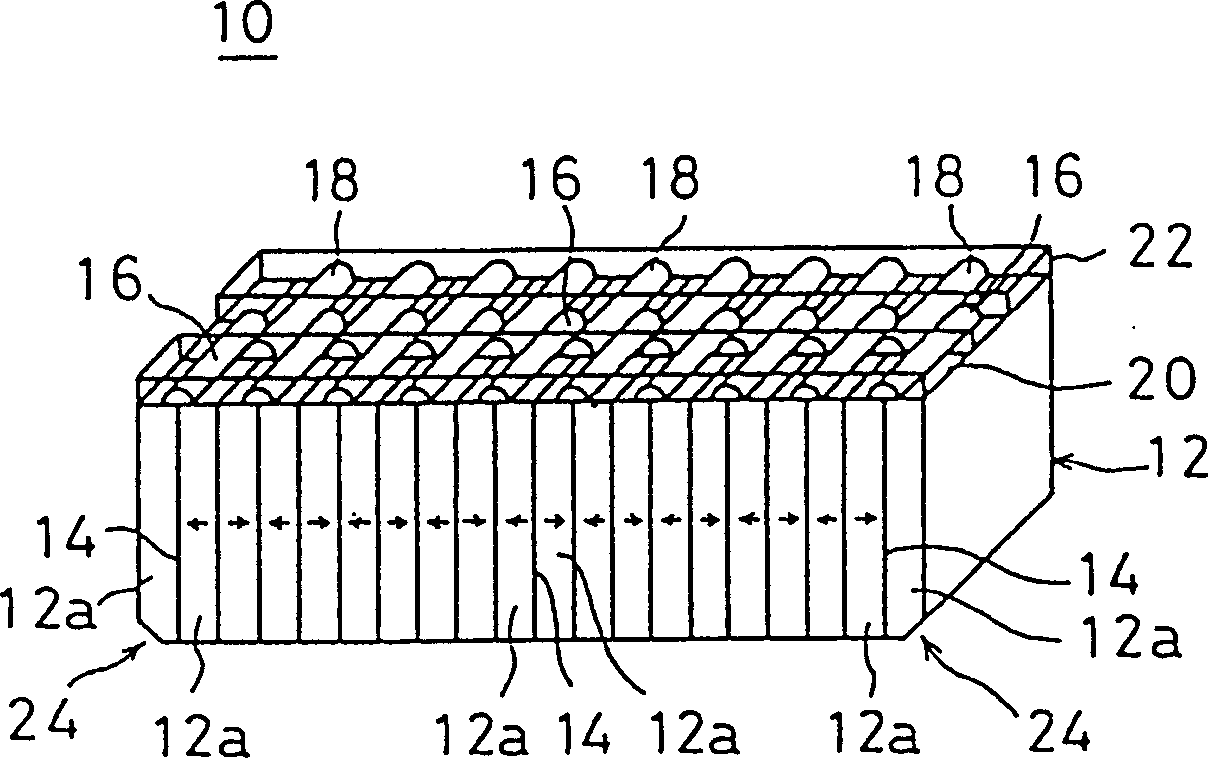

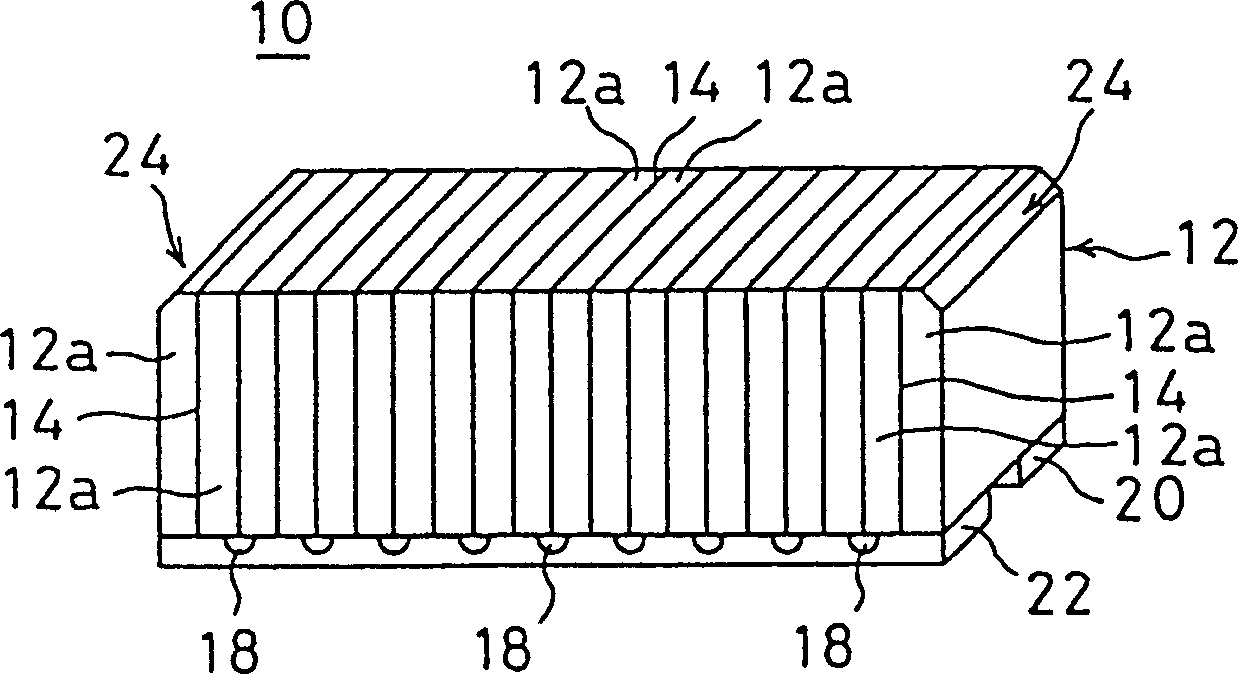

[0047] See figure 1 with figure 2 The piezoelectric resonator 10 includes, for example, a base body 12 in the form of a substantially rectangular block. The base 12 includes, for example, about 20 laminated piezoelectric material layers 12a made of piezoelectric ceramics. These piezoelectric material layers 12a are formed into a uniform size. These piezoelectric material layers 12a are polarized along the longitudinal direction of the base body 12, so that the polarization directions of each pair of adjacent piezoelectric material layers 12a are opposite to each other, such as figure 1 As shown by the arrow in. However, at the opposite end, the piezoelectric material layer 12a is preferably not polarized. In addition, at the opposite end, the piezoelectric material layer 12a may also be polarized.

[0048] The internal electrode 14 is provided between the piezoelectric layers 12 a of the base body 12. Therefore, the internal electrodes are arranged to be substantially perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com