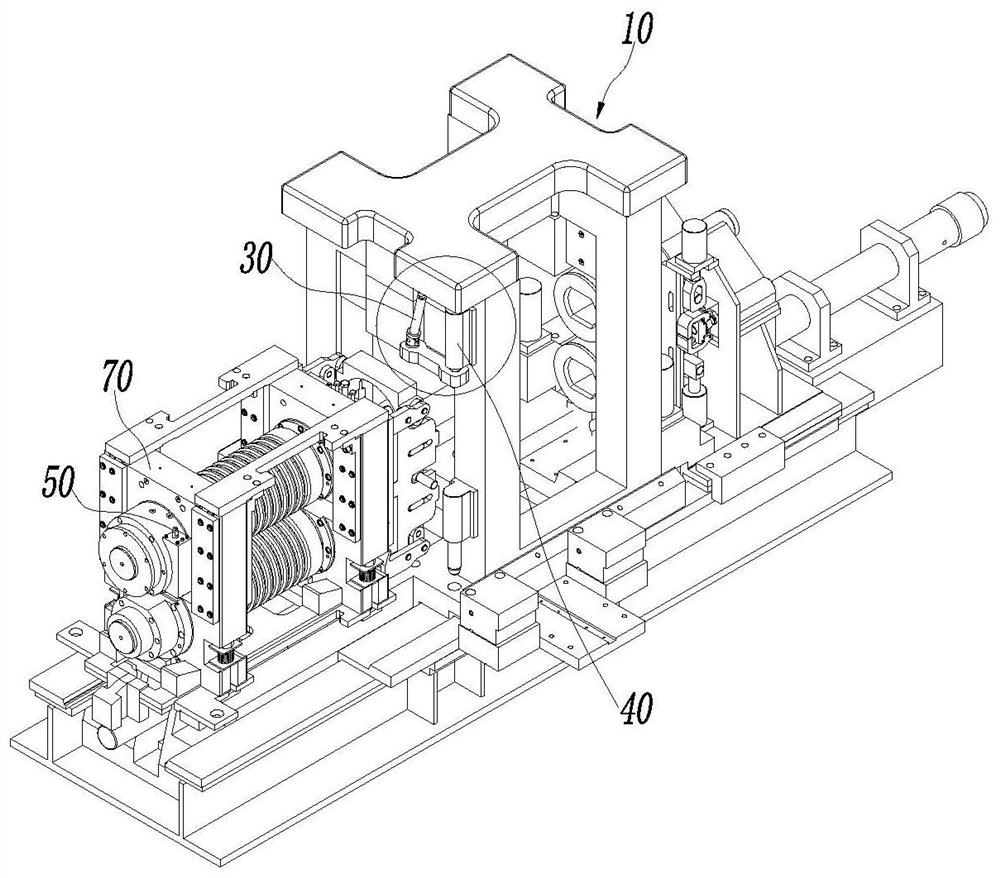

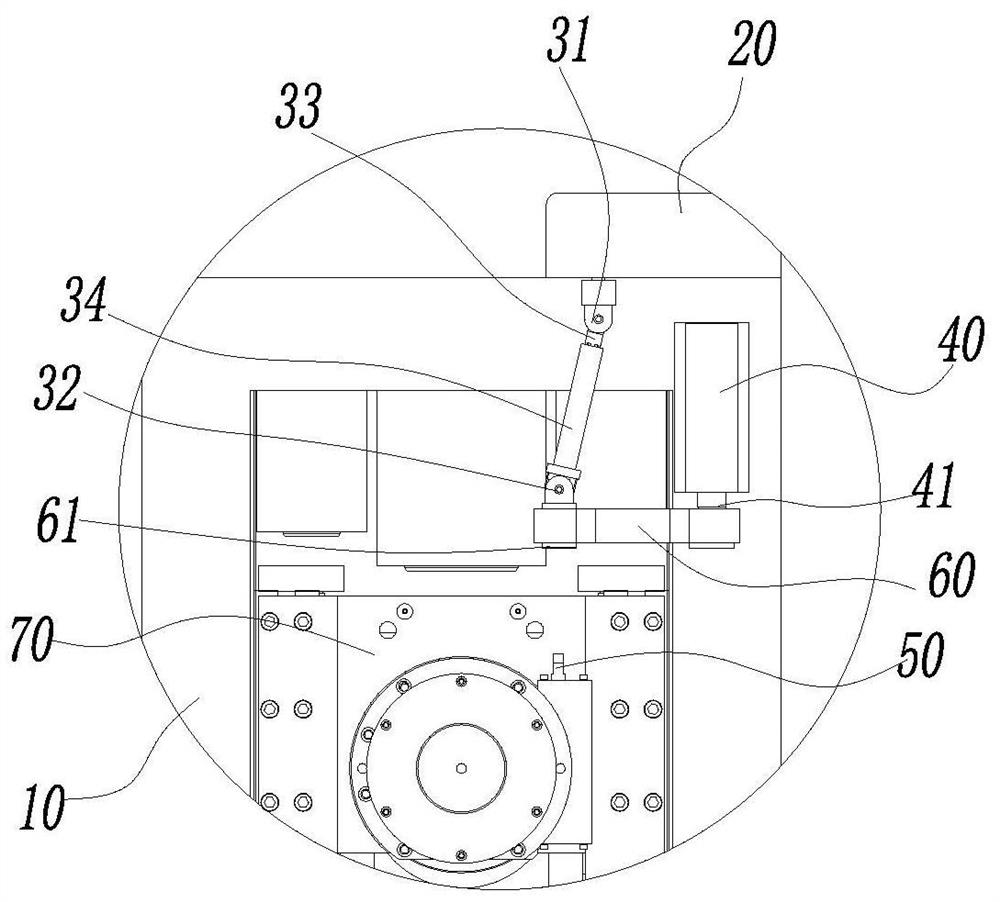

Axial adjusting device of rollers

An adjustment device and axial technology, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of affecting service life, high noise, rolling hole shape deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

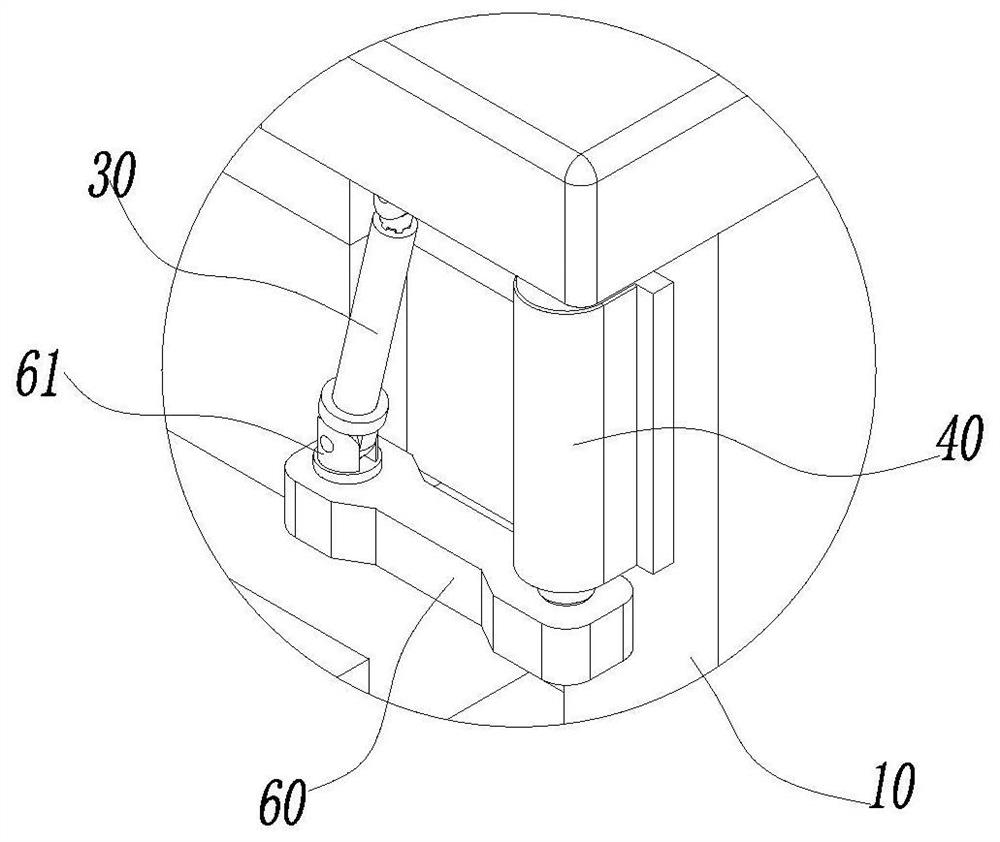

Method used

Image

Examples

Embodiment Construction

[0010] For the convenience of explanation and understanding, some basic orientation and position concepts are explained and defined first. The up and down directions refer to the state where the roll is placed horizontally, and the following description only takes this state as an example for illustration. The rolling mill can be placed in a vertical roll manner to implement rolling.

[0011] Since the surrounding area of the steel is a safety zone during the rolling process, the operator cannot realize the online adjustment during the rolling process. The solution provided by the present invention provides the possibility to realize the online axial adjustment, which significantly improves the control and control of the rolling equipment. Rolling accuracy not only provides assembly guarantee for the reduction of scrap rate, but also can detect whether the product is out of tolerance in time and can quickly correct the error adjustment. In addition, it saves a lot of time an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com