A method of picking and flipping a super-slippery slider

An ultra-slippery and slippery technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of inability to realize the flip of the slider, limited, expensive micro-tweezers equipment, etc., and achieve the easy-to-use and cost-effective picking and flipping method. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

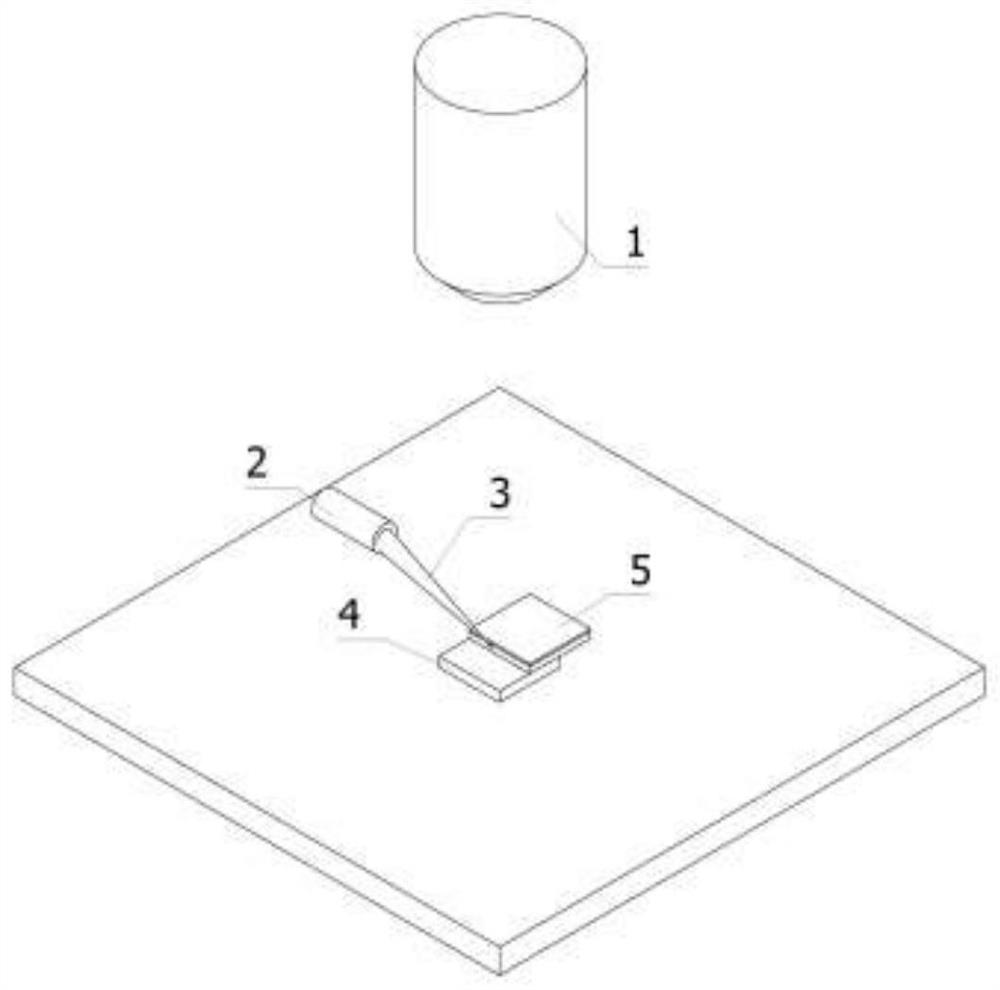

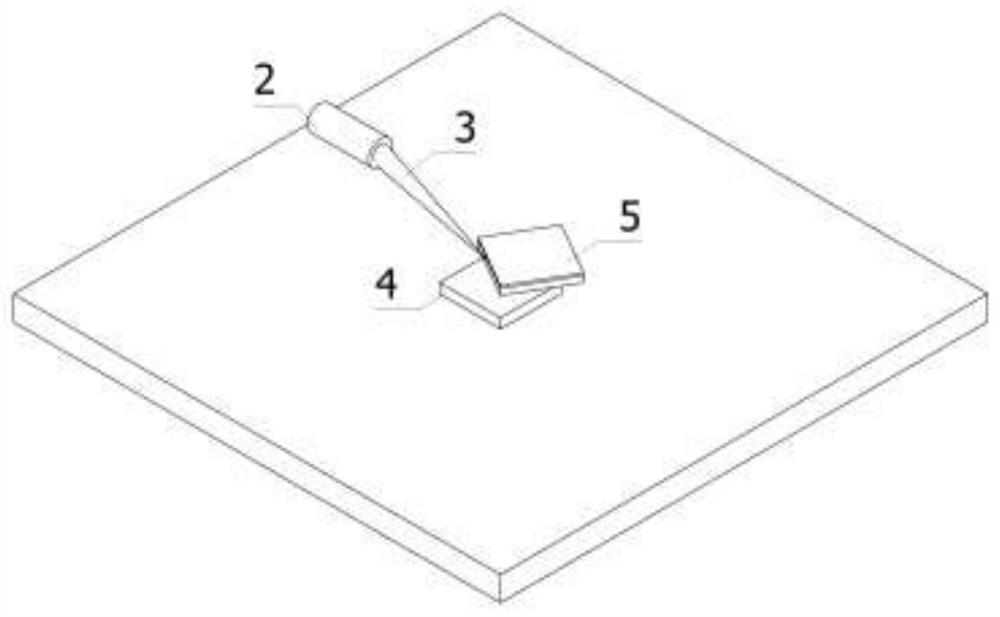

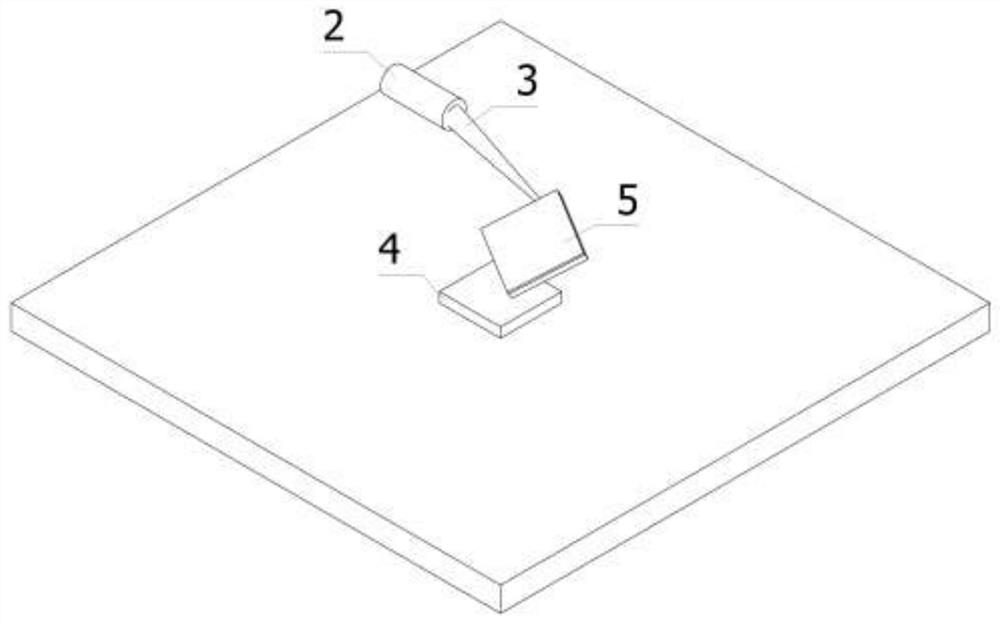

[0028] The method for picking and flipping the ultra-slippery slider of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] Such as figure 1 As shown, the device for picking up and flipping the micrometer ultra-slippery slider includes an optical microscope 1 equipped with a 50x eyepiece, which is used to magnify the field of view so as to facilitate the control of the micronano manipulator (not shown in the figure), and monitor the micrometer The picking and flipping process of the ultra-slippery slider; the displacement accuracy of the micro-nano manipulator is on the order of nanometers, which can control the precise movement of the tungsten probe 3 . The connection device 2 is used to connect the micro-nano manipulator and the probe 3 to manipulate the ultra-slippery slider 5. The probe 3 is preferably a tungsten probe, and the tungsten probe 3 is preferably prepared by electrochemical corrosion, and the radius of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com