Skin material and method for producing same

A manufacturing method and a technology for skin parts, which are applied in chemical instruments and methods, vehicle parts, textiles and papermaking, etc., can solve problems such as non-disclosure, and achieve the effect of suppressing thermal degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Structure of skin parts

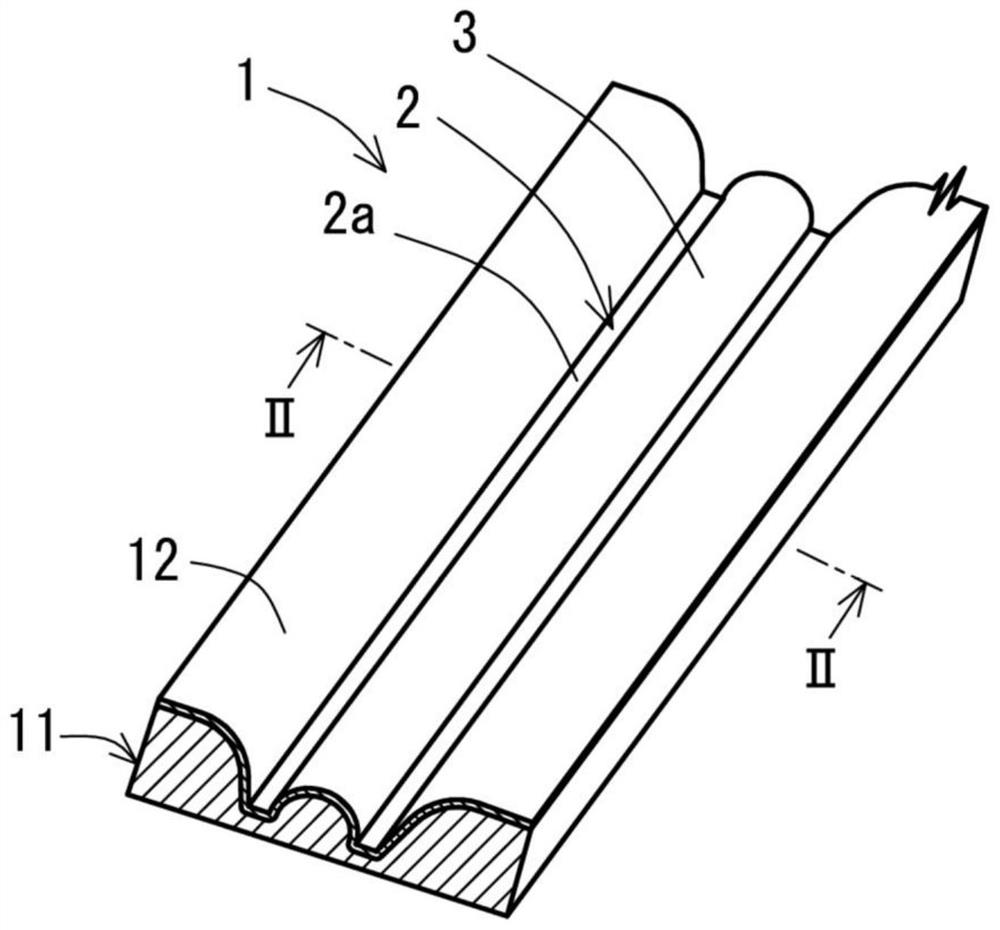

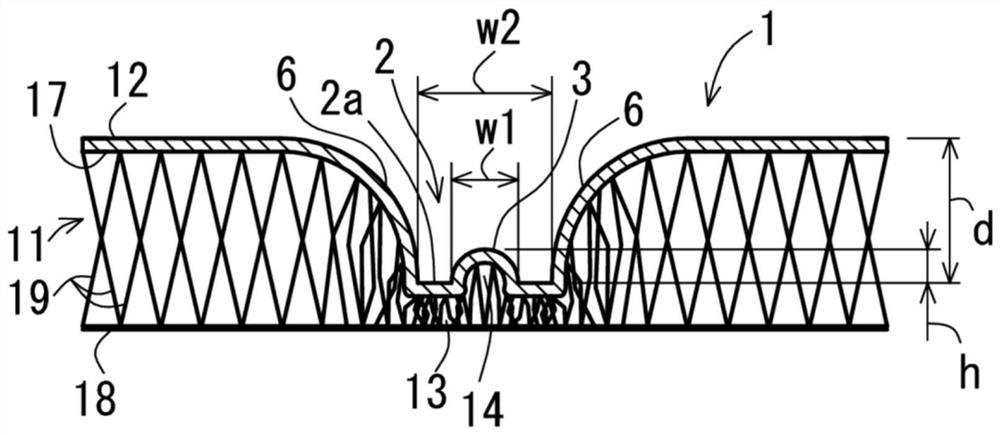

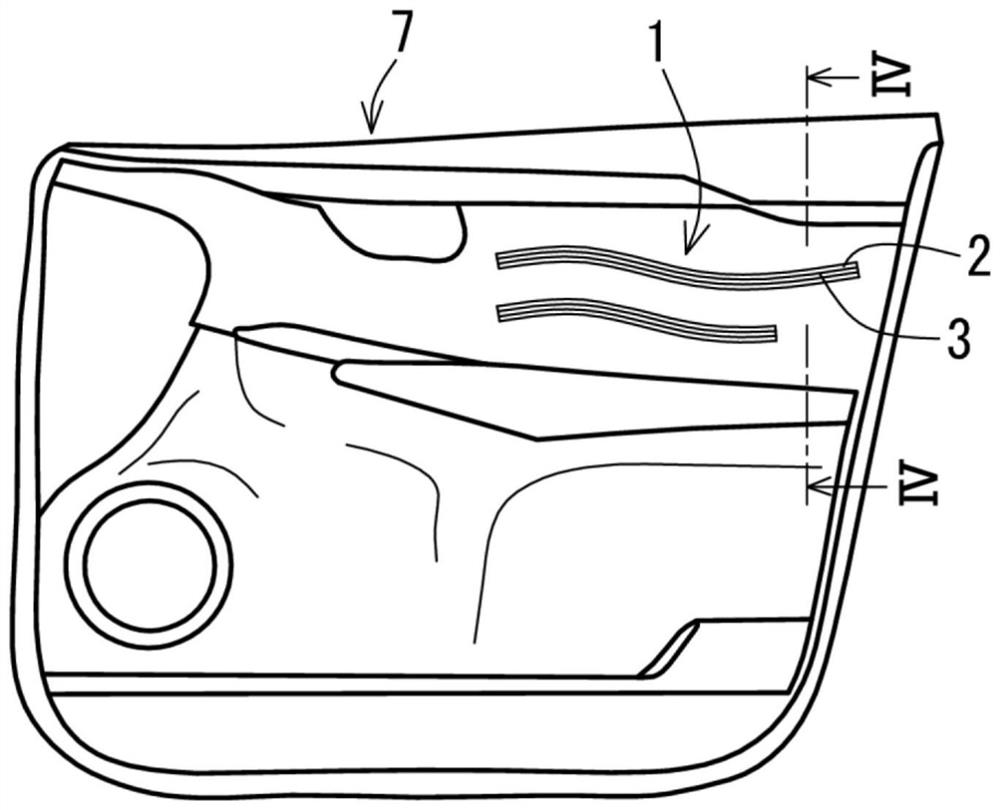

[0059] Such as figure 1 and figure 2 As shown, in the skin material 1 according to this embodiment, the concave portion 2 is formed (shaped) on the surface side, and the convex portion 3 is formed (shaped) on the bottom surface 2 a of the concave portion 2 . The skin material 1 is formed in a flexible sheet shape. In addition, the bottom surface of the skin material 1 is formed in a flat shape without unevenness.

[0060] The above-mentioned concave portion 2 is formed to extend linearly in plan view. In addition, in the longitudinal section along the width direction of the concave portion 2 , the side surfaces 6 rising from both side edges of the bottom surface 2 a are formed in a curved shape away from each other toward the opening side of the concave portion 2 . In addition, the depth d of the recessed part 2 is about 3 mm, and the lateral width w2 of the width direction of the recessed part 2 is about 5 mm.

[0061] The above-men...

Embodiment 2

[0084] Next, the skin material 31 according to the second embodiment and its manufacturing method will be described, and the same reference numerals will be attached to the parts having substantially the same structure as the skin material 1 and its manufacturing method according to the first embodiment, and detailed description will be omitted. Explain the difference between the two.

[0085] (1) Structure of skin parts

[0086] Such as Figure 8 and Figure 9 As shown, in the skin material 31 according to this embodiment, the concave portion 32 is formed (shaped) on the surface side, and the convex portion 33 is formed (shaped) on the bottom surface 32 a of the concave portion 32 . The skin material 31 is formed in a flexible sheet shape. In addition, the bottom surface of the skin material 31 is formed in a flat shape without unevenness.

[0087] The above-mentioned concave portion 32 is formed to extend linearly in plan view. In addition, the above-mentioned protrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com