Backstop bottle cap and its check valve

A technology of check valves and bottle caps, applied in the direction of control valves, valve devices, and functional valve types, which can solve problems such as residues and achieve the effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

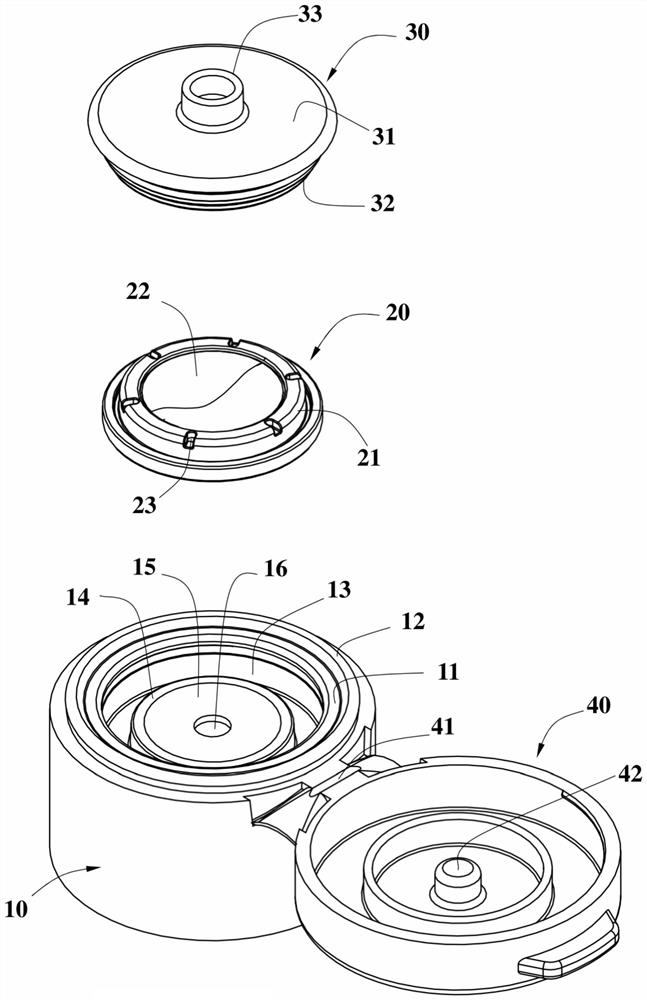

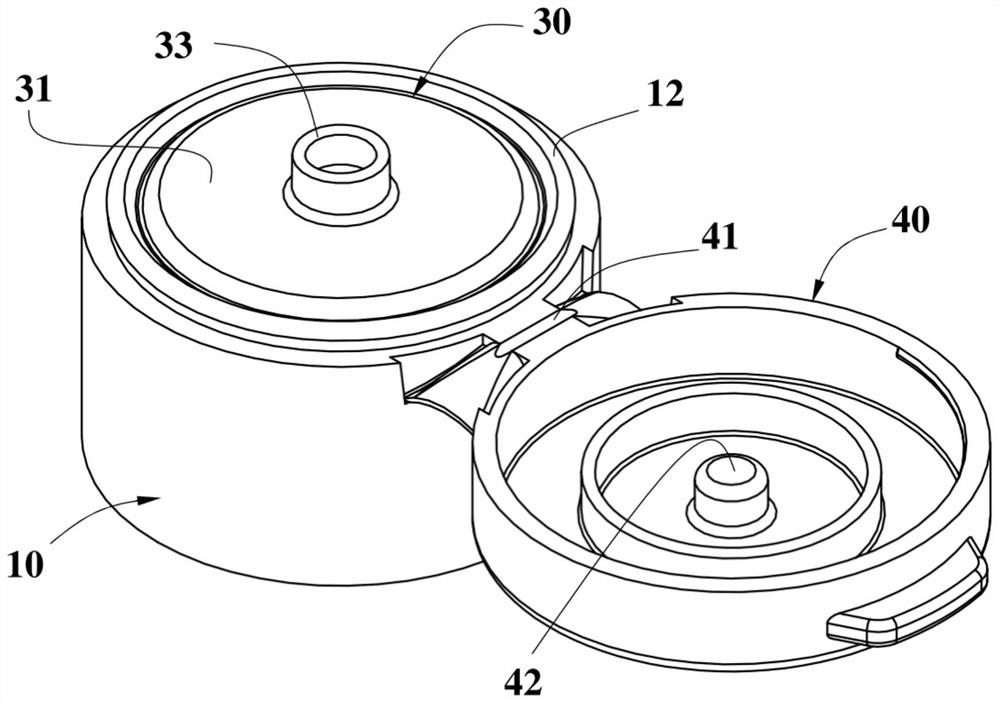

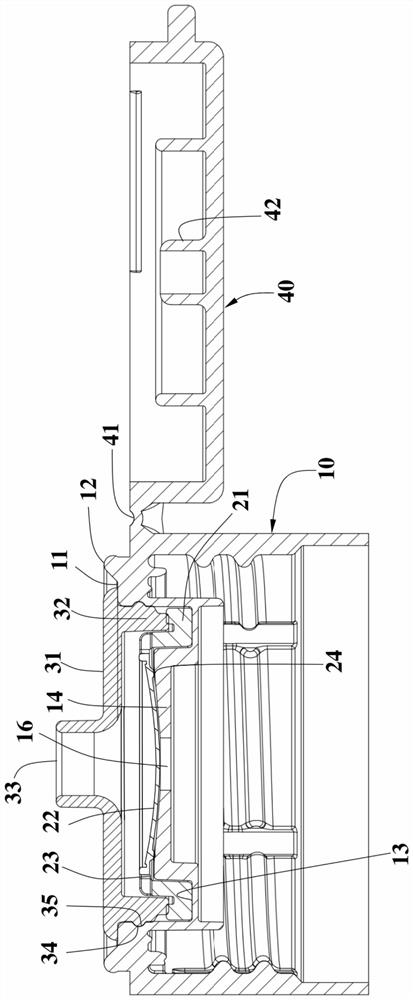

[0037] Such as figure 1 , figure 2 , image 3 The non-return bottle cap of the present invention comprises: a body 10, a cover 40 connected to the body 10, a check valve 20 arranged in the body 10, and an injection member 30 arranged in the body 10 .

[0038] The body 10 is a plastic molded part, including an annular groove 13 recessed from the top surface 11 to form a deep groove, and the body 10 also includes a supporting portion 14 surrounded by the annular groove 13, the supporting portion 14 The top surface is a concave arc surface 15, and a through hole 16 is set at the lowest point of the center of the concave arc surface 15.

[0039] The check valve 20 is a plastic molded part, please cooperate with Figure 4-Figure 8 , the check valve 20 includes an annular base 21, the inner edge of the annular base 21 is connected with an elastically deformable valve plate 22, and the annular base 21 is provided with several outlets close to the inner edge. A sealing convex ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com