A high-level grouting device for prefabricated concrete wall sleeve grouting construction

A technology for grouting concrete walls and sleeves, which is applied in the processing of building materials, construction, building reinforcements, etc., can solve the problems of reducing the bonding and anchoring effect of steel bars, and the quality of grouting cannot be measured, adjusted, and corrected, and achieves simple operation. , avoid measuring and adjusting work, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

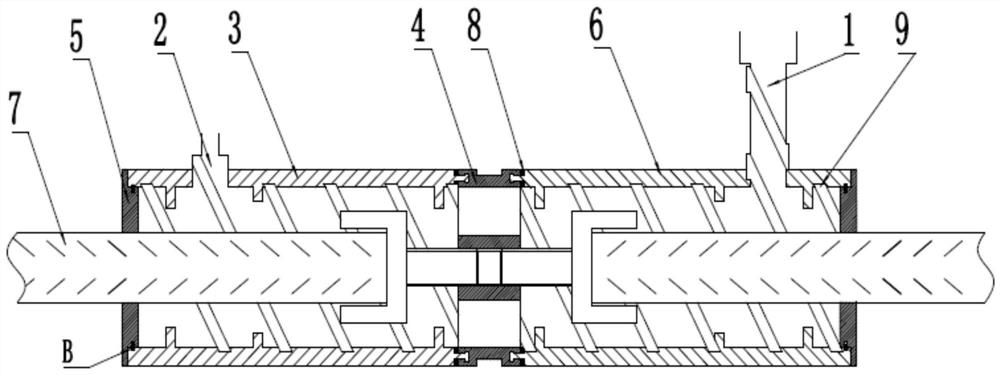

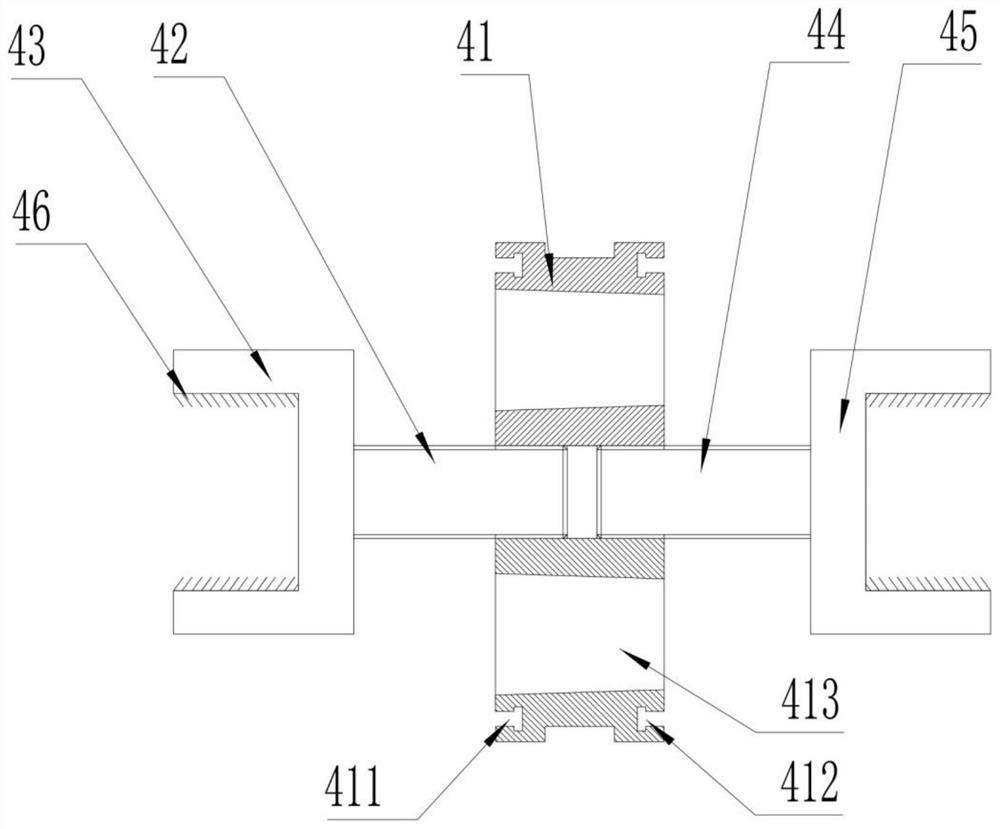

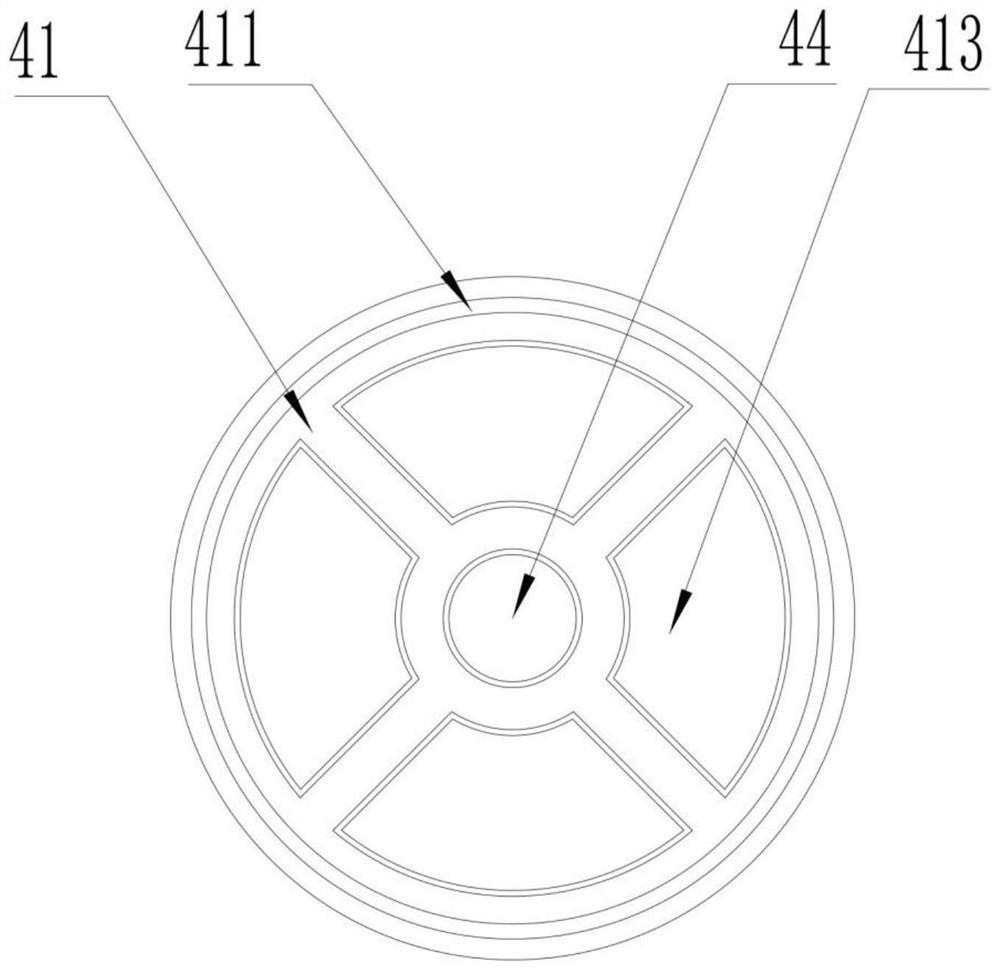

[0082] Such as Figure 1-4 As mentioned above, the present invention provides a high-level grouting device for prefabricated concrete wall sleeve grouting construction, which is characterized in that it includes a first sleeve 3 and a second sleeve 6 coaxial with the first sleeve 3 , the grout discharge hole 2 arranged on the outer peripheral surface of the first sleeve 3, the grouting hole 1 arranged on the outer peripheral surface of the second sleeve 6, and the grouting hole 1 arranged between the first sleeve 3 and the The adjustment device 4 between the second sleeve 6; there is a steel bar 7 on the side of the first sleeve 3 and the second sleeve 4 away from the adjustment device 4; the adjustment device 4 adjusts the first sleeve 3 and the adjustment device 4 The distance between the steel bars 7 in the second sleeve 6; the first sleeve 3 is a hollow cylinder; the slurry discharge hole 2 communicates with the inner hole of the first sleeve 3; the second sleeve 6 is Hol...

Embodiment 2

[0095] Such as Figure 5As shown, the outer diameter of the second sleeve 6 is larger than the outer diameter of the first sleeve 3, and the inner hole size of the second sleeve 6 is larger than the inner hole size of the first sleeve 3. In this implementation The operation process of the example is the same as that of the embodiment 1. The advantage of this embodiment is that the grout is injected from the grouting hole 1. Due to the change of the inner diameter, when the grout in the second sleeve 6 is poured into the first sleeve 3, it will affect the second sleeve 3. The grouting in the sleeve 6 has pressure, which can make the grouting in the second sleeve 6 more substantial. In addition, because the inner wall of the inner hole of the first sleeve 3 and the second sleeve 6 is provided with a connected screw hole 9, so that The grouting material in the sleeve has a helical force in the direction of the grouting hole, which will not cause stagnation or blockage. Thirdly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com