Rounding and shaping die for straight-bar stator iron core

A technology of shaping molds and straight stators, which is applied in the manufacture of stator/rotor bodies, etc., and can solve problems such as plastic skeleton damage, iron core tilting, and up and down misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

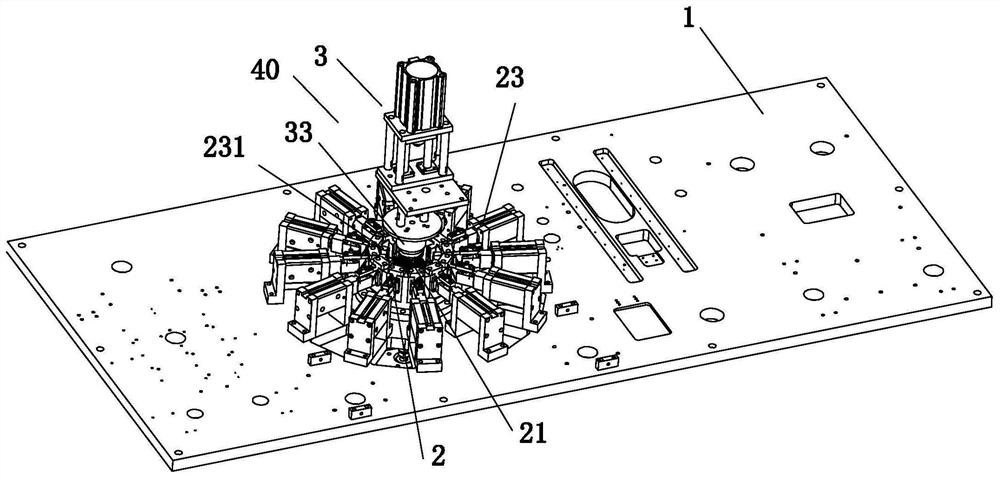

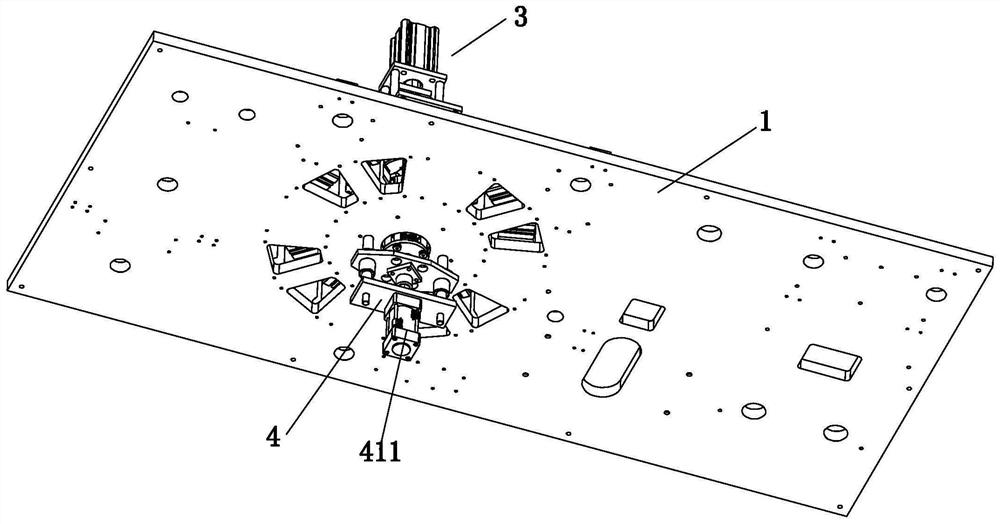

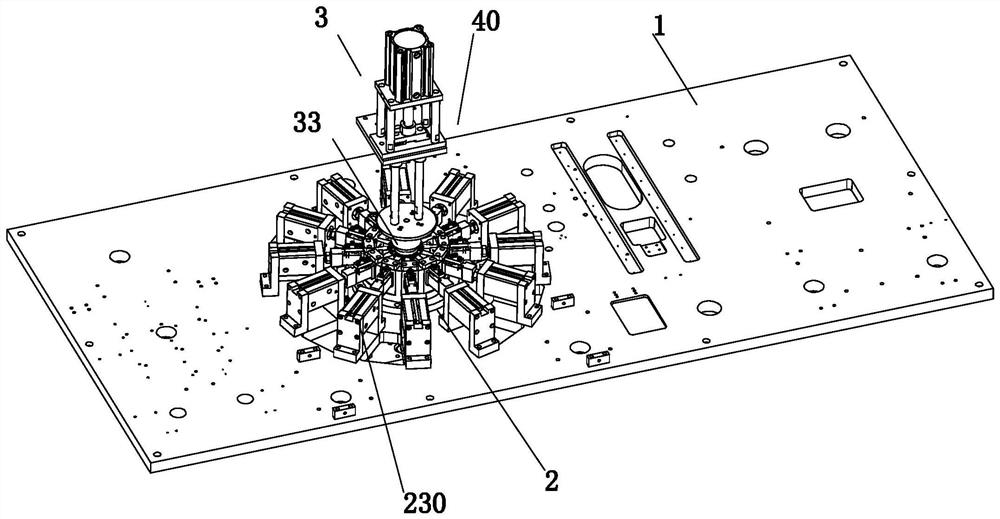

[0064] Embodiment one, such as Figure 1 to Figure 26 As shown, a straight stator core forming mold for forming circles includes a frame 1 , a controller (not shown in the figure) flattening and shaping device 40 and a circle shaping mechanism 2 .

[0065] The circle-pressing and shaping mechanism 2 includes a plurality of circle-pressing and shaping assemblies 23, and the plurality of circle-pressing and shaping assemblies 23 are arranged on the shaping seat 20 at annular intervals, and are used to press the straight fixed iron core on the shaping seat 20 into a ring shape, and make the two ends of the straight stator core 5 lean against each other.

[0066] The flattening and shaping device 40 is arranged on the frame 1, and is used to press the straight stator iron core 5 up and down, so that the positions of the top of the straight stator iron core 5 on the same horizontal plane and the positions of the bottom on the same horizontal plane are kept flush. All positions rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com