Super-viscous PE film material and preparation method thereof

A film material and antioxidant technology, applied in the field of super viscous PE film material and its preparation, can solve the problems of non-repeated peeling use, poor adhesion of PE film, etc., so as to improve physical bonding force, avoid the use of glue, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

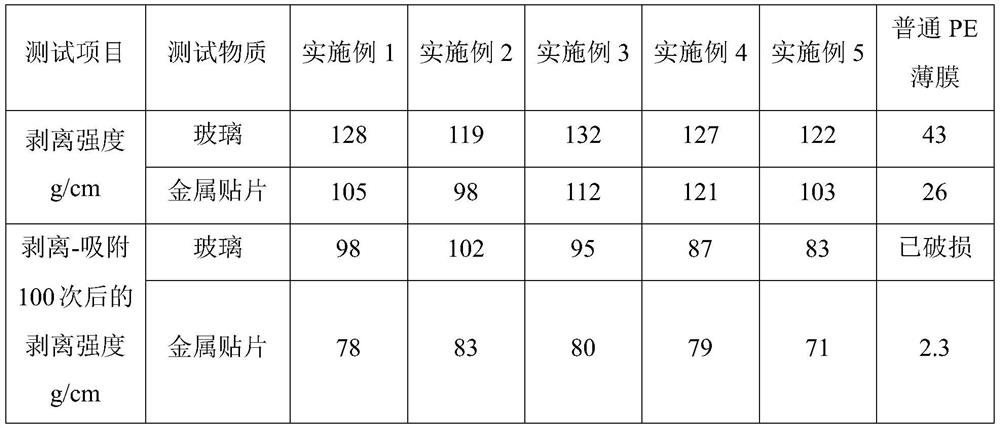

Embodiment 1

[0025] According to the weight percentage, mix high-density polyethylene 10%, low-density polyethylene 84.2%, N-hydroxyethyl acrylamide 4%, processing aid calcium stearate 0.8%, and phenolic antioxidant 1010 1.0%. It is processed in a twin-screw extruder with a diameter ratio of 38:1. The temperature of the twin-screw extruder from the feeding section to the die is 150℃, 150℃, 155℃, 155℃, 160℃, 160℃, 160 ℃, 160℃, 160℃, extrude and granulate to obtain PE film material masterbatch;

[0026] After the PE film material masterbatch is blown into a film, UV cross-linking is performed under ultraviolet light with a wavelength of 370 nm for 2 hours to prepare a super-adhesive PE film material.

Embodiment 2

[0028] According to weight percentage, linear low-density polyethylene 95.6%, N-hydroxyethyl acrylamide 3%, processing aid calcium stearate 0.3%, zinc stearate 0.3%, amine antioxidant V703 0.4%, amine Antioxidant UV3808PP5 0.4% is mixed and then added to a twin-screw extruder with a length-to-diameter ratio of 36:1. The temperature of the twin-screw extruder from the feeding section to the die is 165℃, 165℃, 165℃, 170°C, 175°C, 175°C, 180°C, 180°C, 180°C, through extrusion granulation to obtain PE film material masterbatch;

[0029] After the PE film material masterbatch is blow-molded into a film, UV cross-linking is performed under ultraviolet light with a wavelength of 370 nm for 1.5 hours to prepare a super-adhesive PE film material.

Embodiment 3

[0031] According to the weight percentage, low-density polyethylene 92.9%, N-hydroxyethyl acrylamide 5%, zinc stearate 0.9%, phosphite antioxidant 168 1.2% are mixed and then added into the twin screw with a length to diameter ratio of 38:1 Processing in the extruder, the temperature of the twin-screw extruder from the feeding section to the die is 180℃, 180℃, 185℃, 185℃, 185℃, 190℃, 190℃, 190℃, and 190℃. Extrusion granulation to obtain PE film material masterbatch;

[0032] After the PE film material masterbatch is blown into a film, UV crosslinking is performed for 2.5 hours under ultraviolet light with a wavelength of 365 nm to prepare a super-adhesive PE film material.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap