Pipeline sewage discharge device for hydraulic engineering

A sewage device and water conservancy engineering technology, which is applied in the direction of water supply devices, sewer pipe systems, waterway systems, etc., can solve the problems of easy blockage and re-blockage of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

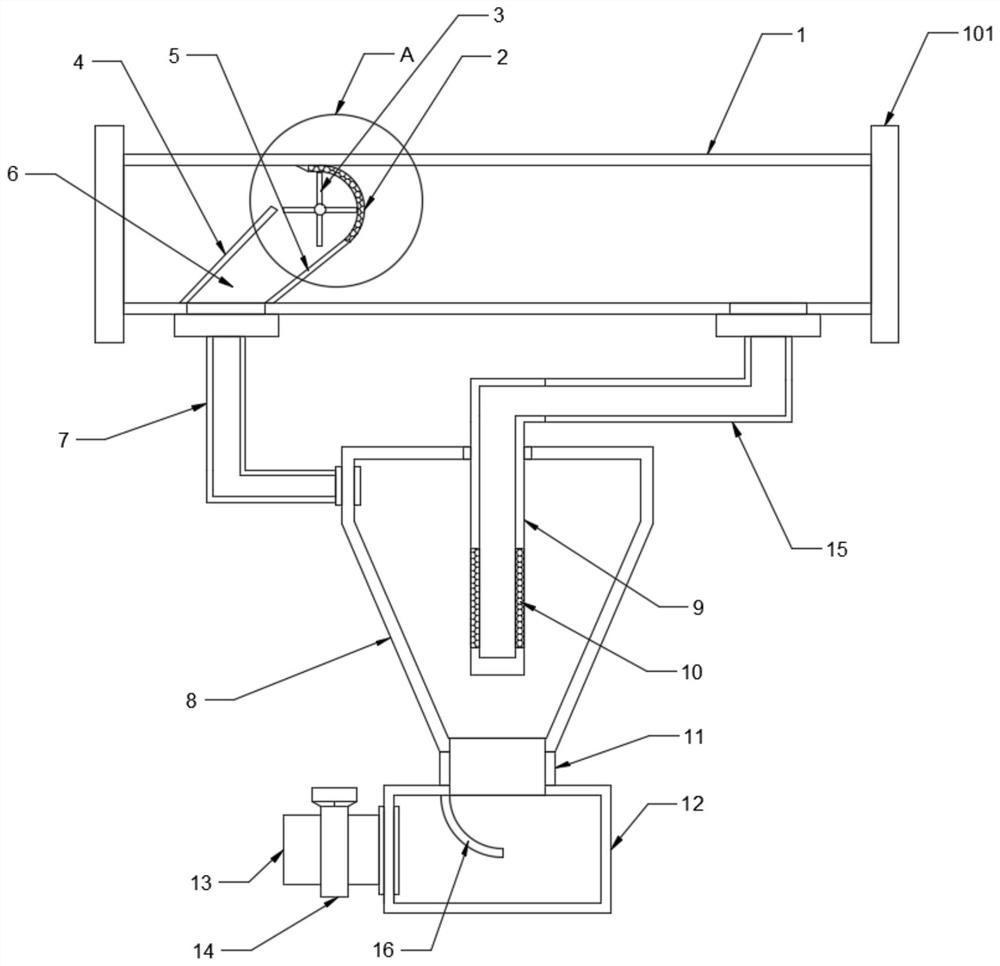

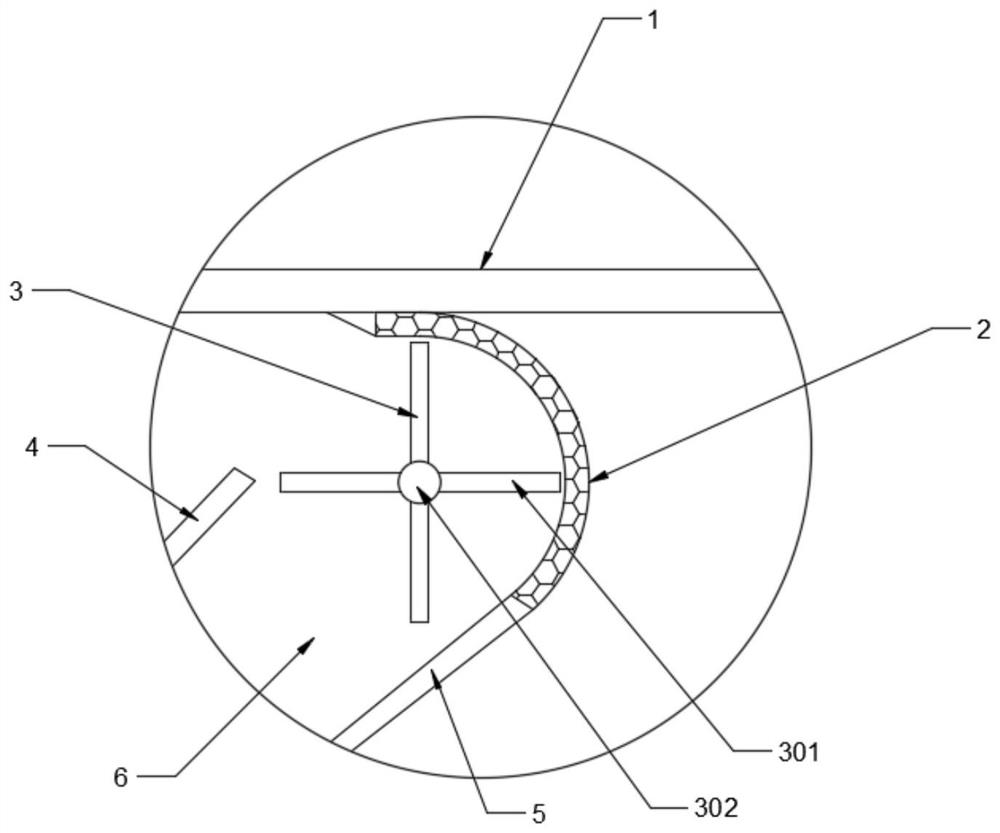

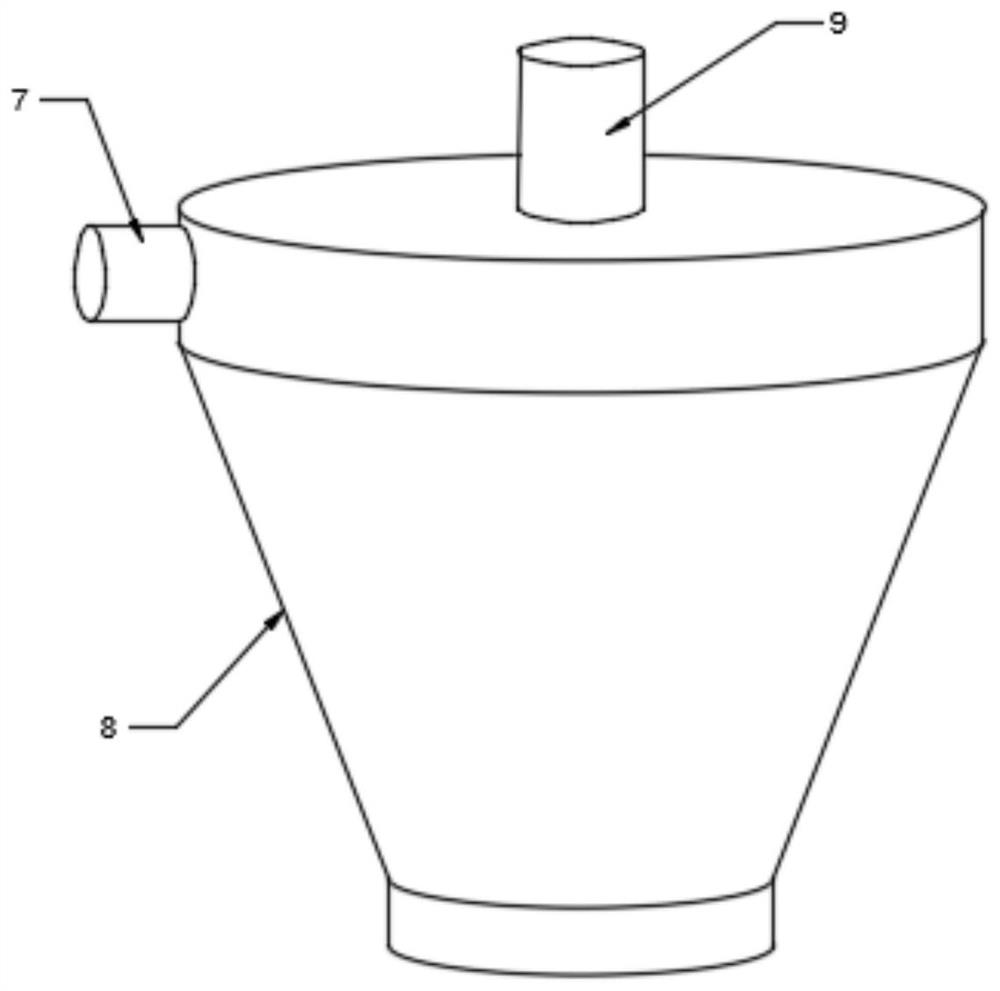

[0020] see Figure 1-3 , in an embodiment of the present invention, a pipeline sewage device for water conservancy projects, including a device body; the device body includes a splicing main pipe 1, and connecting flanges 102 are provided at both ends of the splicing main pipe 1, and are connected and fixed to the outside through the connecting flange 102 ; The splicing main pipe 1 is provided with a filter cover 2, the filter cover 2 intercepts the sludge in the splicing main pipe 1, the filter cover 2 is a hemispherical filter, the filter cover 2 is located on the upper part of the splicing pipe 1 and is connected to the splicing main pipe 1 The top wall is fixedly connected; the front side of the filter cover 2 is provided with a first deflector 4, the first deflector 4 is arranged obliquely, and the first deflector 4 is fixedly connected with the bottom wall of the splicing main pipe 1; the first deflector 4. Guide the water flow of the spliced main pipe 1 to the upper h...

Embodiment 2

[0025] In an embodiment of the present invention, a pipeline sewage device for water conservancy projects includes a device body; the device body includes a splicing main pipe 1, and connecting flanges 102 are provided at both ends of the splicing main pipe 1, and are connected and fixed to the outside through the connecting flange 102; The splicing main pipe 1 is provided with a filter cover 2, and the filter cover 2 intercepts the sludge in the splicing main pipe 1. The filter cover 2 is a hemispherical filter net, and the filter cover 2 is located on the upper part of the splicing pipe 1 and is on top of the splicing main pipe 1. The wall is fixedly connected; the front side of the filter cover 2 is provided with a first deflector 4, the first deflector 4 is arranged obliquely, and the first deflector 4 is fixedly connected with the bottom wall of the splicing main pipe 1; the first deflector 4 The water flow of the spliced main pipe 1 is directed to the upper half of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com