A method for making a composite material pipe gallery model in a geotechnical centrifuge

A geotechnical centrifuge and combined material technology, applied in computer-aided design, instrument, geometric CAD, etc., can solve the problem of model stiffness equivalence, and achieve the effect of large selection of materials, simple and controllable processing process, fast and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

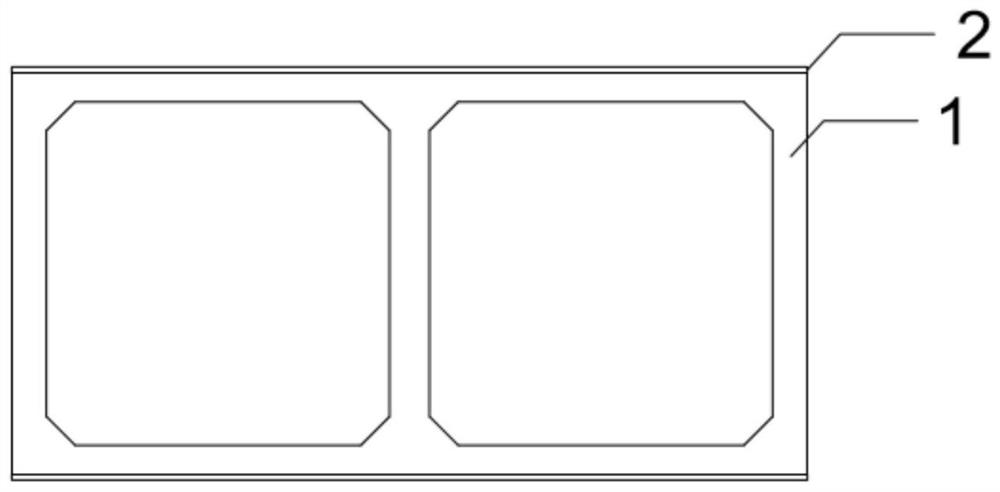

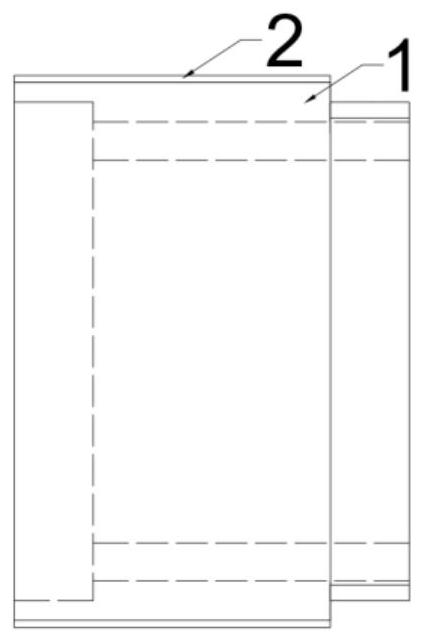

[0037] This embodiment provides a method for making a pipe gallery model of composite materials in a geotechnical centrifuge. The cross-sectional size of the pipe gallery model after scale is determined by calculating the equivalent principle of stiffness, and then two materials are combined to make it; the main solution is in geotechnical centrifugal In the machine test, the size of the prototype pipe gallery is too large to be directly tested, and the ordinary scale model is not easy to process, and it is difficult to achieve the equivalent stiffness and deformation similarity to the prototype pipe gallery.

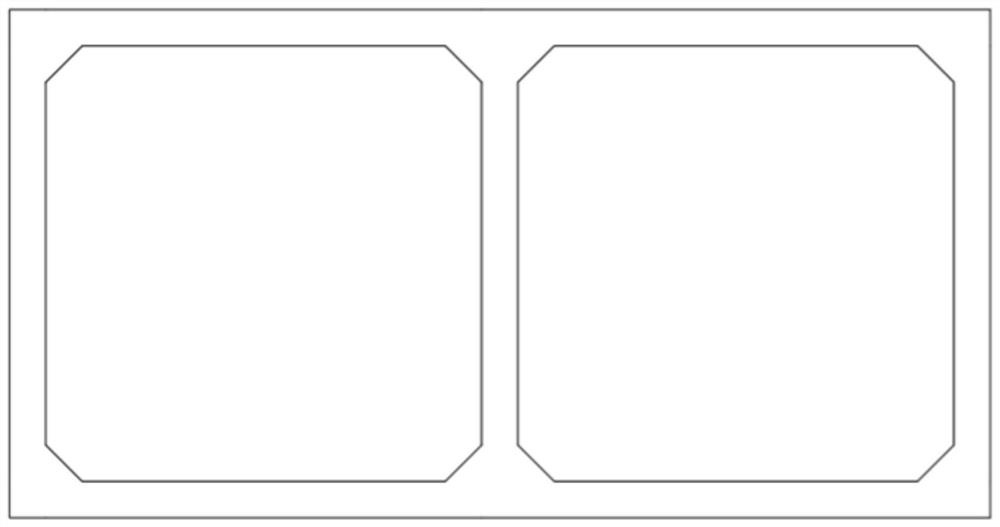

[0038] The pipe gallery model is composed of multiple scaled pipe joints connected. Each scaled pipe joint is roughly a rectangular bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com