Sealant material composition and pneumatic tire

A material composition and pneumatic tire technology, which can be applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., and can solve problems such as adverse effects on driving performance such as handling stability and reduced sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

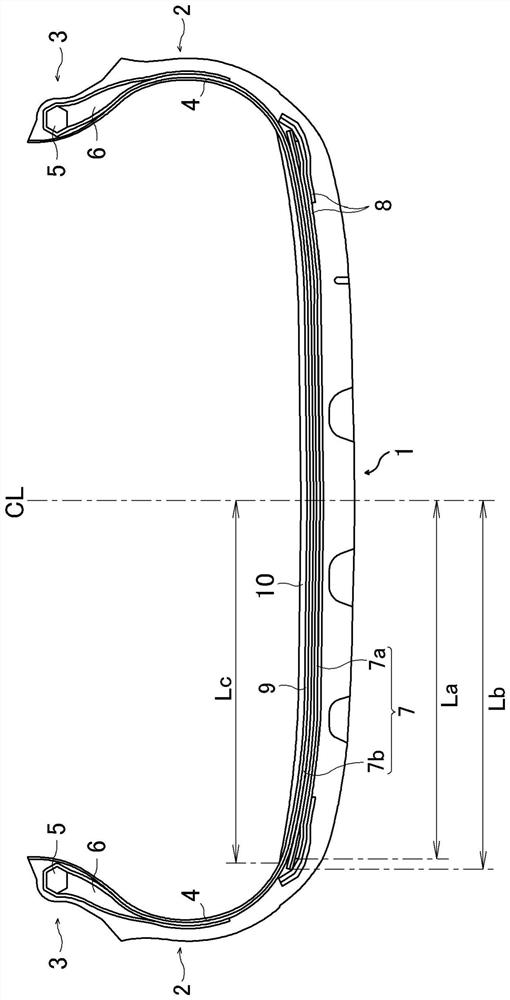

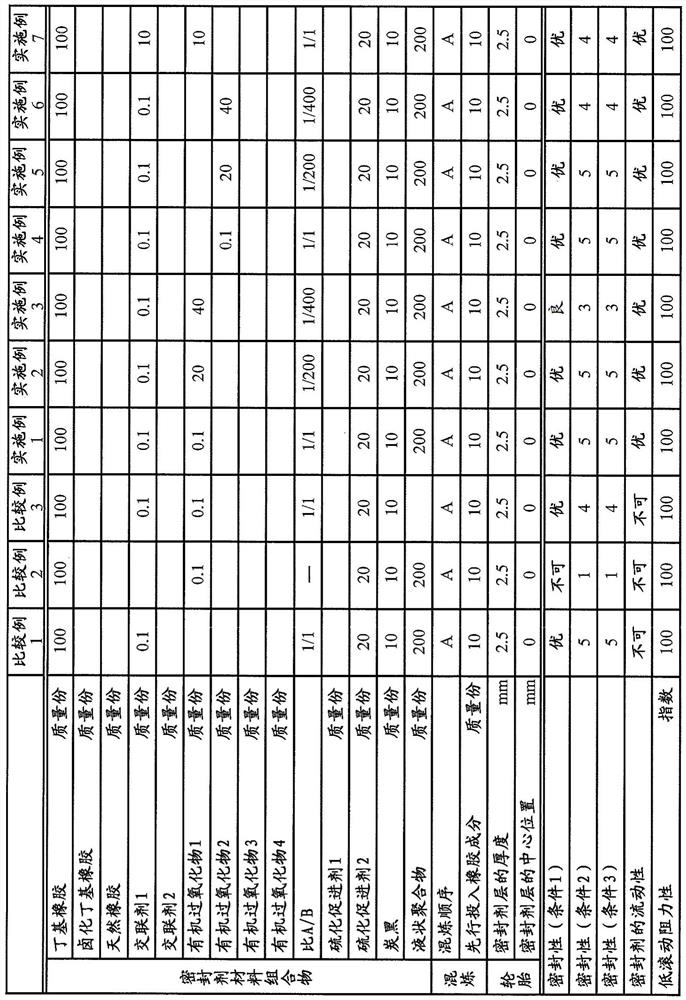

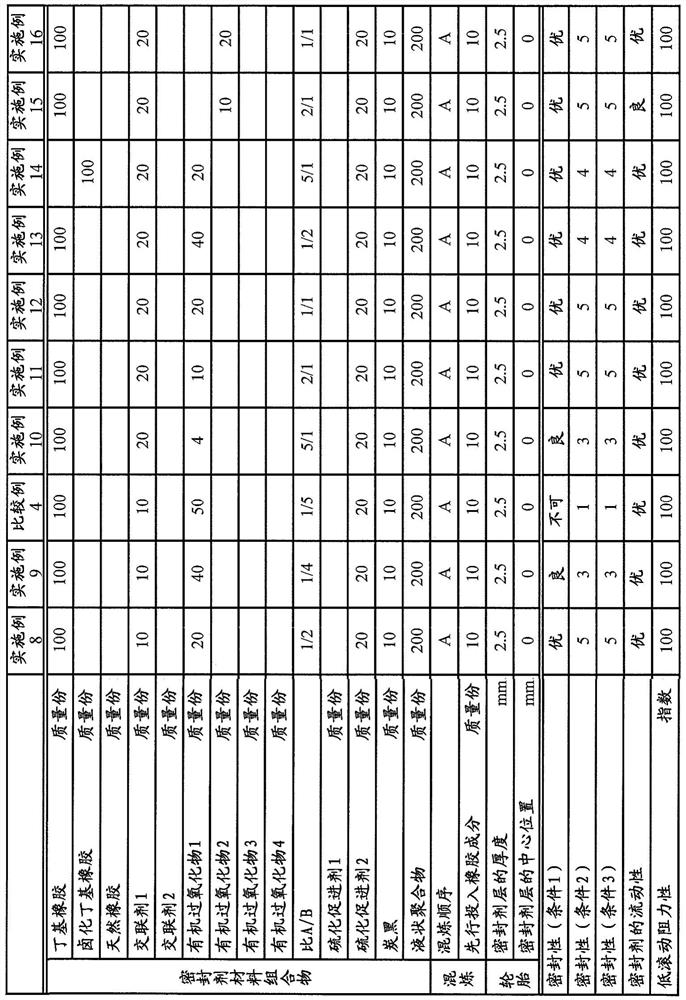

[0050] Made in tire size 215 / 60R16, with figure 1 In the shown basic structure, in a pneumatic tire having a sealant layer made of a sealant on the tire radial inner side of the inner liner at the tread portion, the composition of the sealant material composition constituting the sealant layer, the sealant material The order of kneading the components of the composition, the amount of the rubber component to be charged in advance, the thickness of the sealant layer in the pneumatic tire, and the distance from the center of the sealant layer to the tire equator were adjusted as shown in Tables 1 to 6. Tires of Comparative Examples 1-9 and Examples 1-45.

[0051] Also, in either case, the inner liner is composed of halobutyl rubber. The column of "kneading procedure" of Tables 1 to 6 shows which of the two kinds of kneading procedures (A to C) shown in Table 7 is used.

[0052] For these test tires, the following test methods were used to evaluate the sealing performance, the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap