Garden design trimmer and trimming method thereof

A pruner and gardening technology, which is applied in the field of garden design pruners and their pruning, can solve the problem that the pruning size of trees cannot be adjusted, and achieve the effect of increasing the aesthetic feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

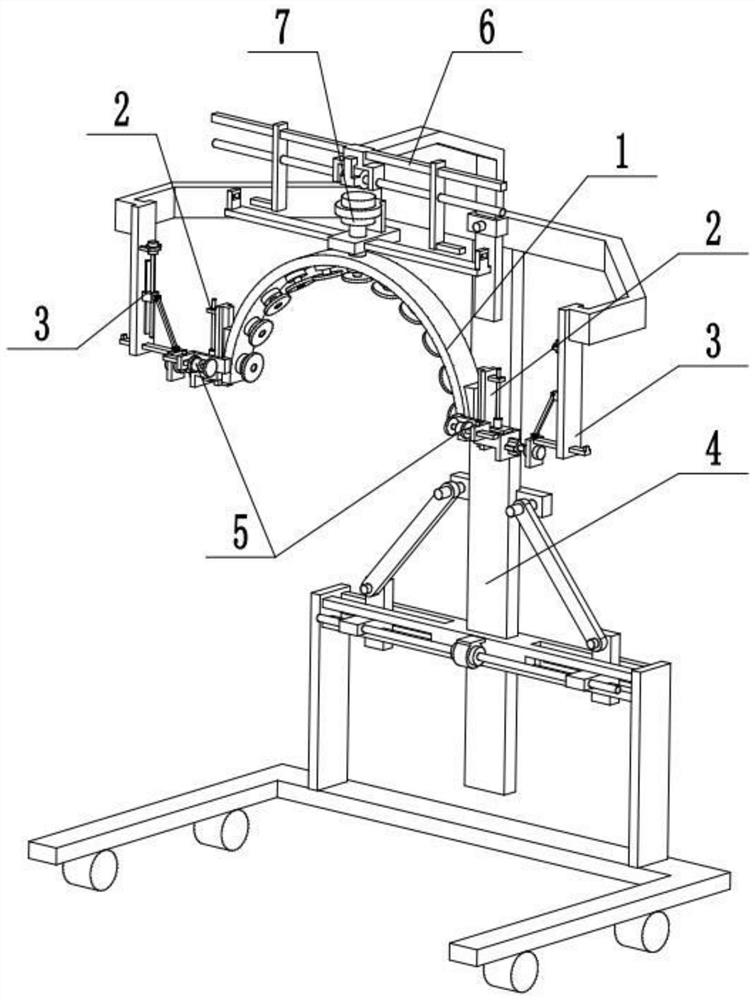

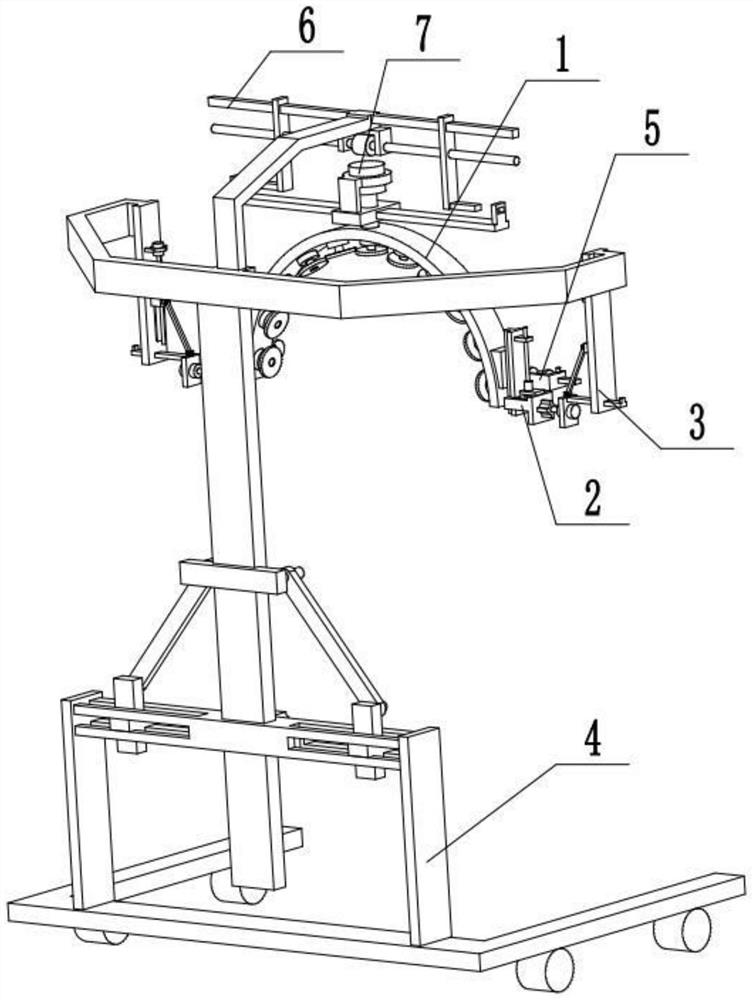

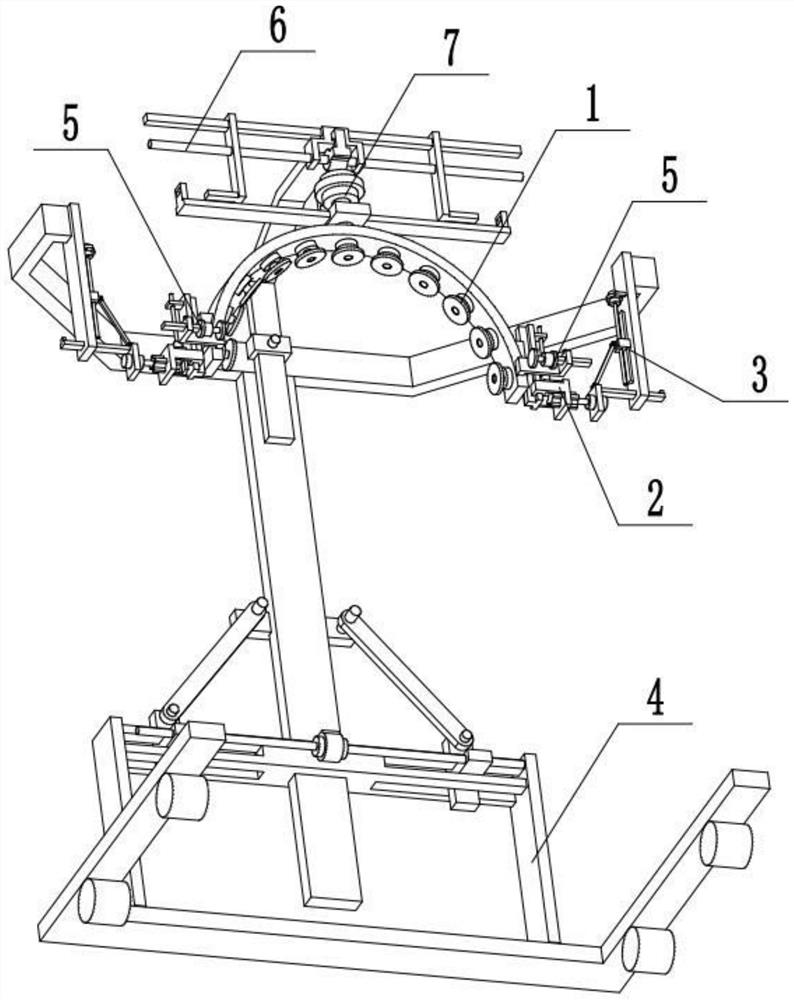

[0035] Combine below Figure 1-9 Description of this embodiment, a garden design trimmer, including a main trimmer 1, a side insert 2, a side rotation control mechanism 3, a frame 4, a side trimmer 5, an upper fixed insert 6 and an upper rotary drive 7, the The two ends of the main trimmer 1 are respectively provided with a side insert 2, and the two side inserts 2 are respectively connected with two side rotation control mechanisms 3, and the two side rotation control mechanisms 3 are symmetrically arranged on the upper end of the frame 4, and the main The two ends of the trimmer 1 are respectively fixedly connected with a side trimmer 5, the upper rotary driver 7 is connected to the main trimmer 1, the upper fixed insert 6 is connected to the upper end of the frame 4, and the two ends of the upper rotary driver 7 are respectively Correspondingly set with the two ends of upper fixed plug-in 6. When in use, move the frame 4 to the vicinity of the trees, adjust the height of t...

specific Embodiment approach 2

[0037] Combine below Figure 1-9 To illustrate this embodiment, the main trimmer 1 includes an arc seat 1-1, a first motor 1-2, a first cutter head 1-3, a T-shaped frame 1-4 and an adjustment block 1-5; The inner end of the seat 1-1 is uniformly surrounded and fixedly connected to a plurality of first motors 1-2, the output shafts of the plurality of first motors 1-2 are respectively fixedly connected to the first cutter head 1-3, and the two ends of the arc-shaped seat 1-1 The ends are respectively fixedly connected with a T-shaped frame 1-4, and the two T-shaped frames 1-4 are respectively fixedly connected with an adjusting block 1-5, and the two adjusting blocks 1-5 are respectively connected with two side inserts 2; The upper end of seat 1-1 is connected with fixed insert 7. In use, when the arc seat 1-1 rotates around a semicircular track or rotates under the drive of the upper rotary drive member 7, multiple first motors 1-2 start to drive multiple first cutter heads 1...

specific Embodiment approach 3

[0039] Combine below Figure 1-9 To illustrate this embodiment, the side insert 2 includes a chute seat 2-1, a T-shaped chute 2-2, a socket 2-3, a through hole 2-4, a convex chute 2-5, and a second motor 2 -6 and the first screw rod 2-7; the inner end of the chute seat 2-1 is provided with a T-shaped chute 2-2, and the T-shaped frame 1-4 is slidingly fitted and connected in the T-shaped chute 2-2, and the chute The outer end of the seat 2-1 is fixedly connected to the socket 2-3, and the socket 2-3 is provided with a through hole 2-4 and four convex chute 2-5, and the four convex chute 2-5 surrounds the through hole 2 -4 is arranged and communicated with the through hole 2-4, the second motor 2-6 is fixedly connected to the socket 2-3 through the motor frame, and the output shaft of the second motor 2-6 is connected to the first screw rod 2-7 through a coupling , the protruding line chute 2-5 is connected to the first screw rod 2-7 through thread fit; the side rotation contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com