Automatic defoaming multifunctional rectifying tower device and rectifying process thereof

A multi-functional, rectifying tower technology, applied in fractionation, vacuum distillation, essential oils/spices, etc., can solve problems such as affecting product quality, easy formation of foam, etc., and achieve the effect of wide application, elimination of foam, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

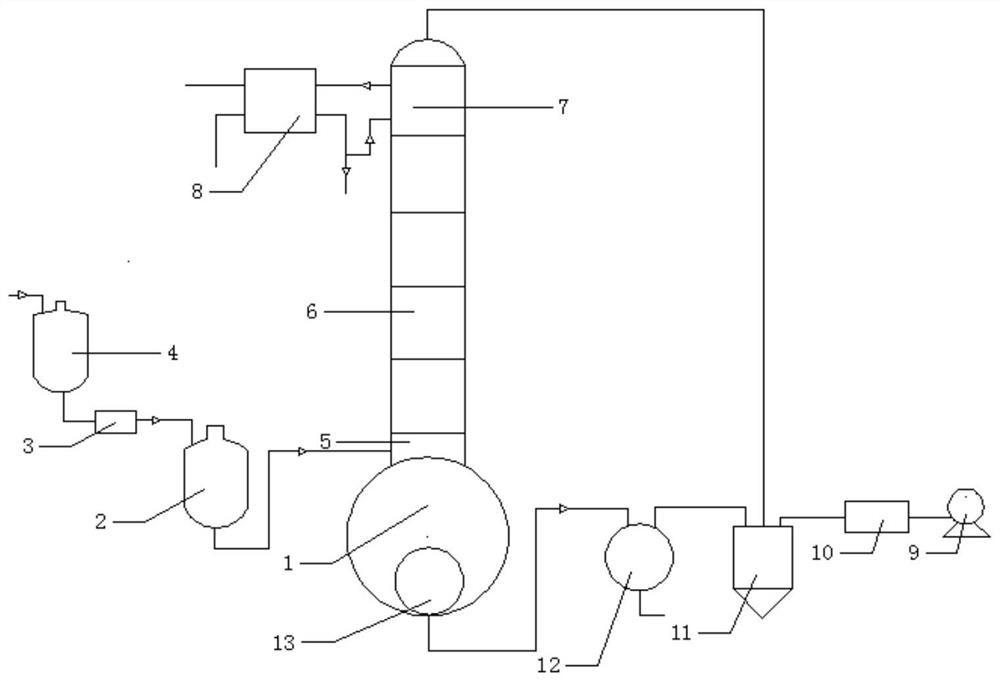

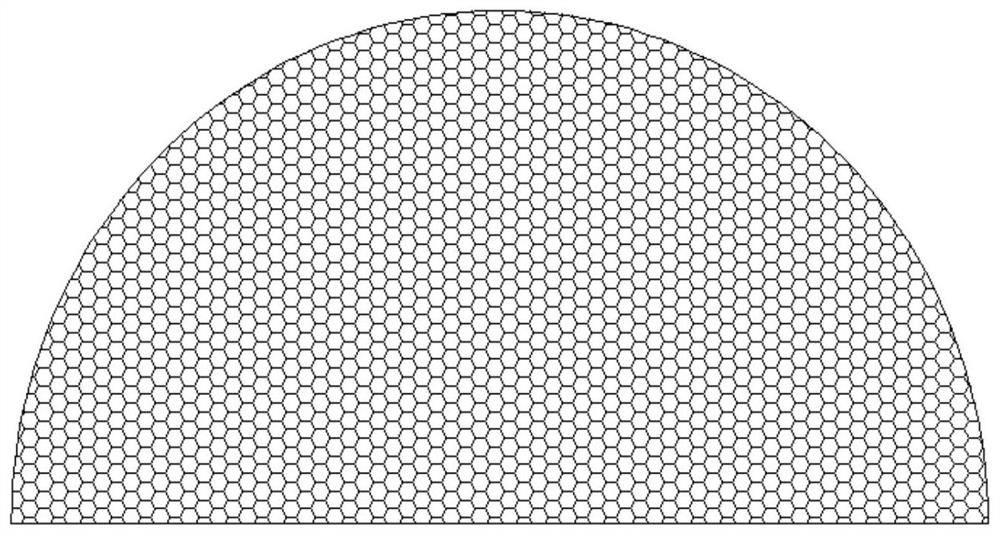

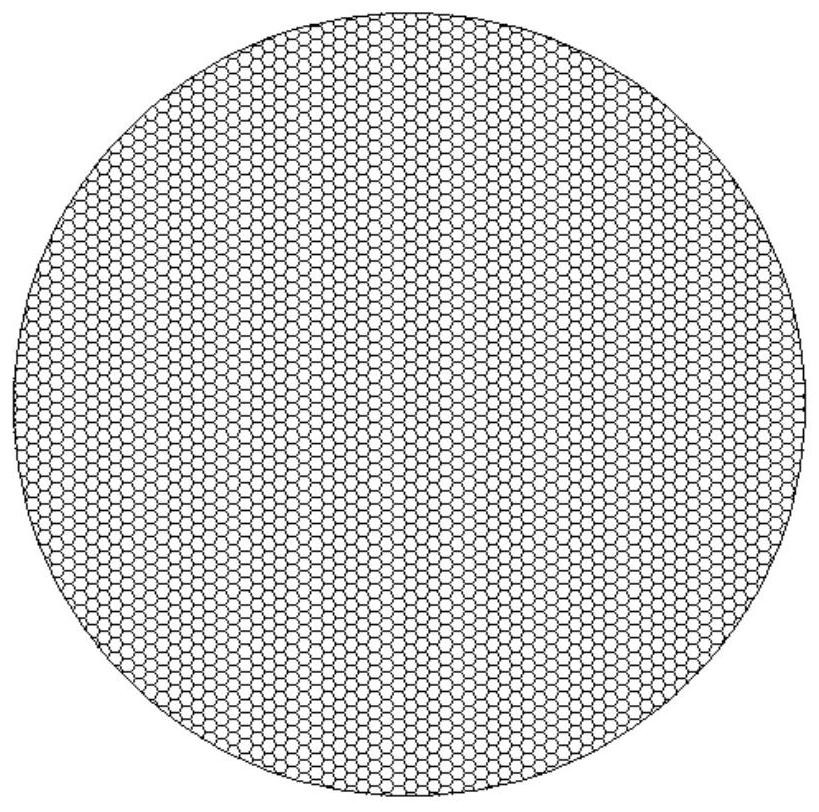

[0041] Such as Figure 1 to Figure 4 As shown, an automatic defoaming multifunctional rectification tower device includes a tower kettle 1, a metering tank 2, a filter 3, a raw material storage tank 4, a defoaming device 5, a tower body 6, a vacuum system, a heating system 13, a condensation Cooling system, the bottom of the defoaming device 5 is connected to the top of the tower kettle 1, the top of the defoaming device 5 is connected to the bottom of the tower body 6, and the raw material storage tank 4, filter 3 and metering tank 2 are connected in series through pipelines The feed port of the tower still 1 is connected, the condensation cooling system is installed on the top of the tower body 6, and the top of the tower body 6 is connected to the vacuum system through a pipeline, the heating system 13 is installed in the tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com