Gluing device for plate splicing machine and gluing method thereof

A technology of a gluing device and a jigsaw machine, which is applied in the direction of an adhesive application device, a device for applying liquid to a surface, a coating, etc., can solve the problem of many human resources, etc., and achieve the effect of saving human resources and a simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

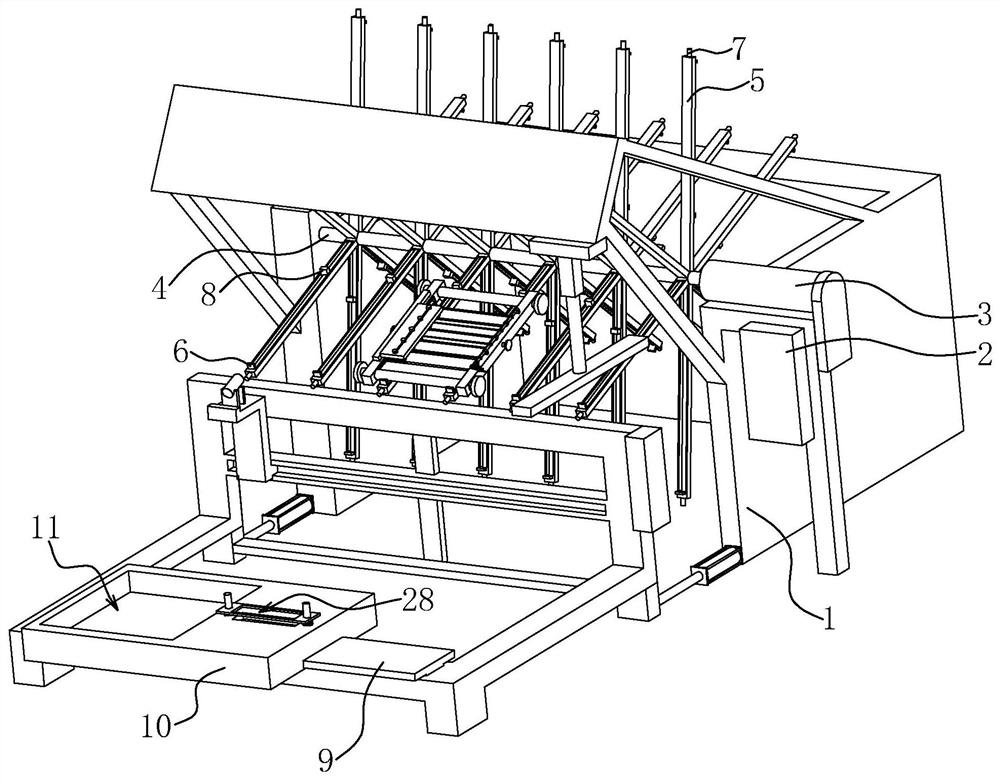

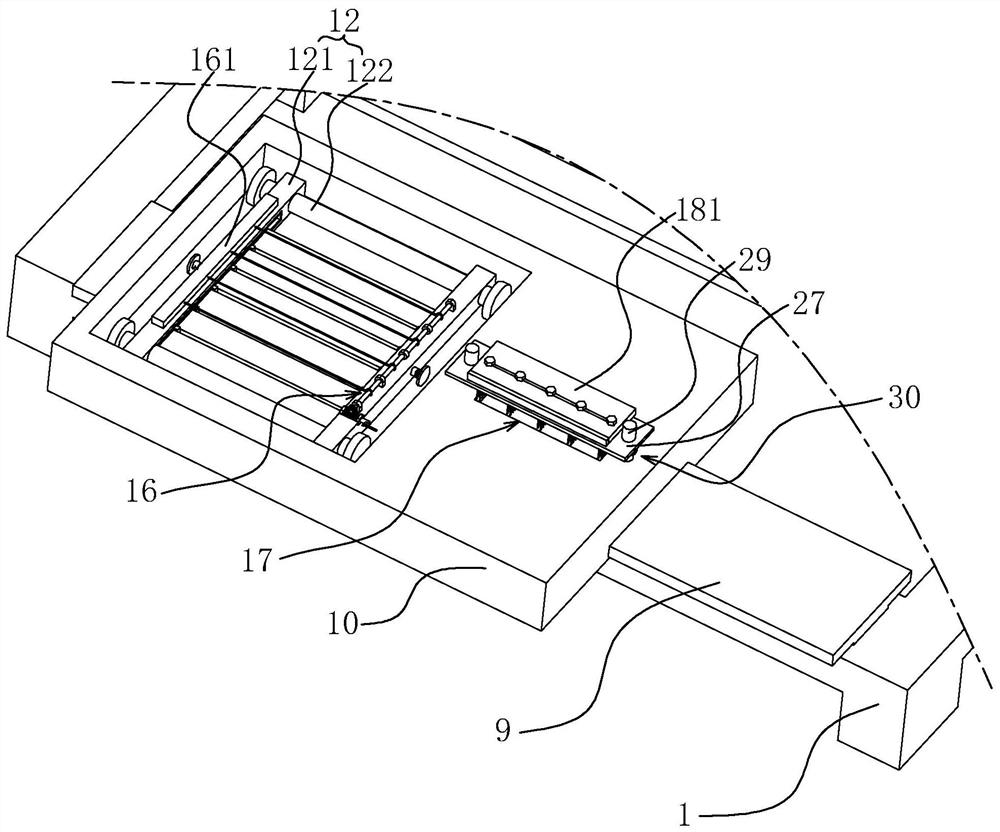

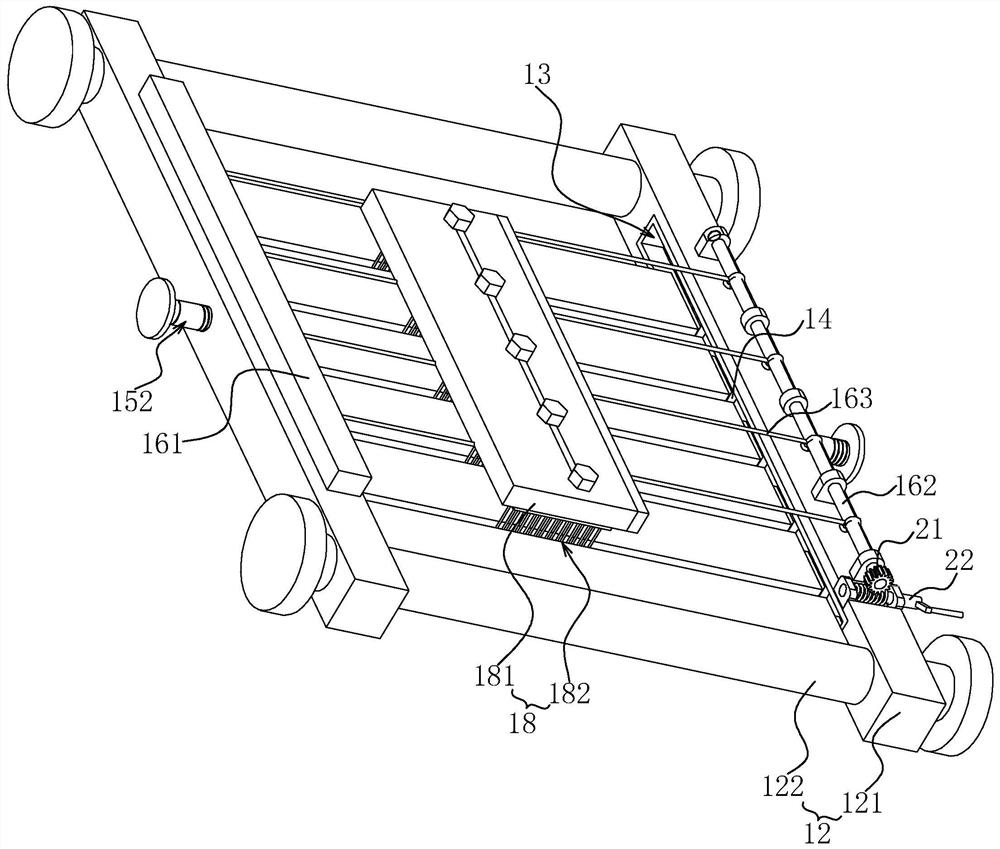

[0040] The following is attached Figure 1-6 Give further details on this application.

[0041] See figure 1 , Jigsaw machine includes frame 1. The frame 1 is provided with a first power device 2, the first power device 2 is connected with a transmission mechanism 3, and the transmission mechanism 3 is provided with a cross beam 4. When in use, the first power device 2 generates power, and the transmission mechanism 3 drives the cross beam 4 to turn over. A plurality of longitudinal beams 5 are connected to the cross beam 4. A fixed indenter 6 and a screw rod 7 are provided on the side of the longitudinal beam 5 away from the cross beam 4. The screw rod 7 is screwed with a movable indenter 8. When in use, place the wooden strip on the longitudinal beam 5 in the loading area, so that the wooden strip is perpendicular to the longitudinal beam 5, and then drive the movable indenter 8 through the screw rod 7 to move, so that the movable indenter 8 and the fixed indenter 6 cooperate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap