Carrying device for belleville spring production

A carrier device and disc spring technology, which is applied in the field of carrier devices for disc spring production, can solve the problems of not being able to fix the disc spring, inconvenient pick and place of the disc spring, etc., and achieve the effect of convenient pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

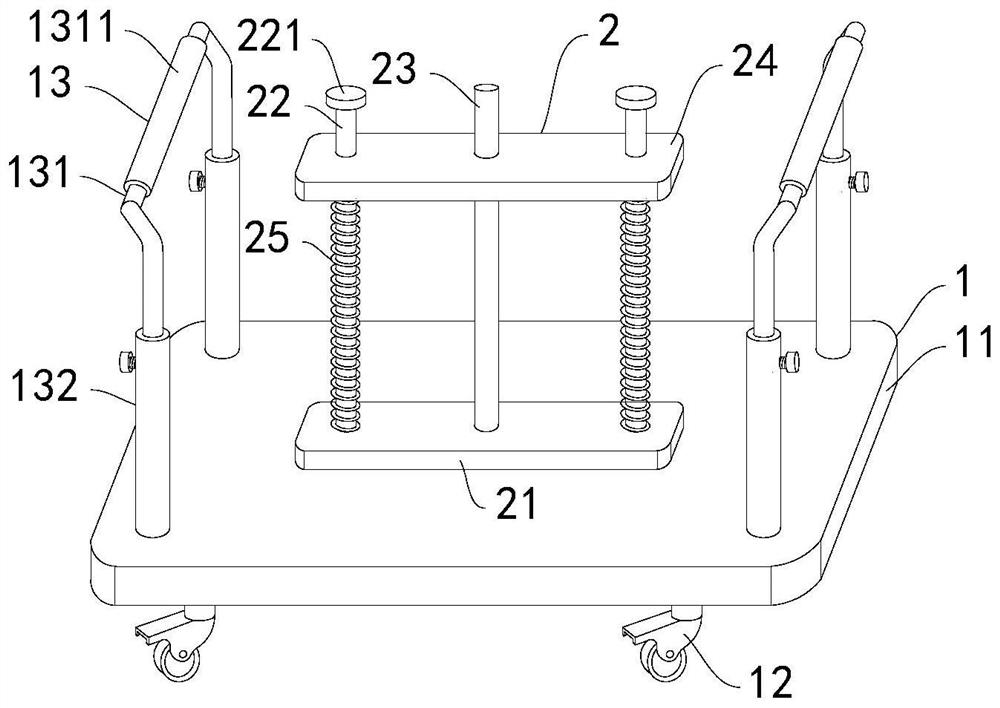

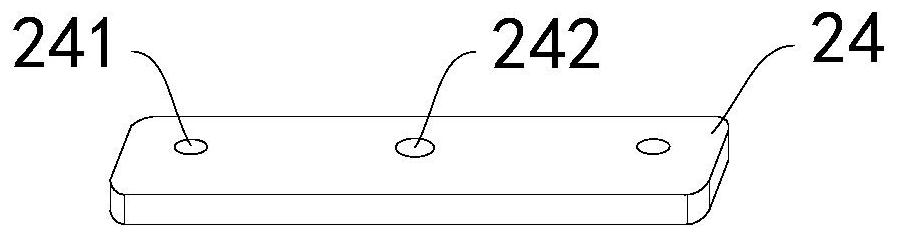

[0023] like Figure 1-3 As shown, a carrier device for disc spring production includes a vehicle body 1 and a fixing frame 2; the vehicle body 1 includes a bottom plate 11, rollers 12 and a handlebar 13; four rollers 12 are installed at the bottom of the vehicle plate 1, and the top of the bottom plate 11 The handlebars 13 are installed on both sides; the fixing frame includes 2 including a mounting plate 21, a support rod 22, a fixing column 23, a support plate 24 and a spring 25. There is a support rod 22, a fixing column 23 is installed in the middle of the top of the mounting plate 21, first through holes 241 are provided at both ends of the support plate 24, and two support rods 22 are respectively arranged in the two first through holes 241, and the support plate 24 There is a second through hole 242 in the middle, the fixing column 23 is arranged in the second through hole 242, the two support rods 22 are sleeved with springs 25, and the upper and lower ends of the two ...

Embodiment 2

[0025] On the basis of the first embodiment, a braking device is installed on the roller 12 .

Embodiment 3

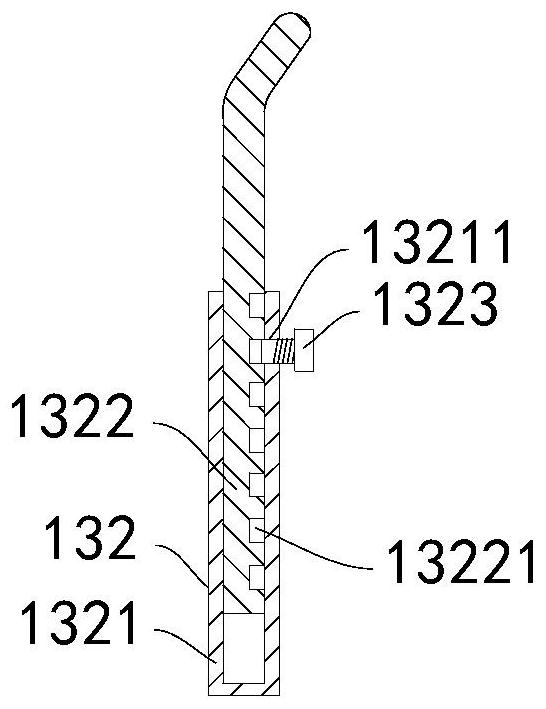

[0027] On the basis of the second embodiment, the handlebar 13 includes a handlebar 131 and a telescopic rod 132 .

[0028] The handle bar 131 is provided with an anti-skid cover 1311, and the anti-skid cover 1311 is a rubber cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com