Antimonous oxide safe storage device

A technology of antimony trioxide and storage devices, which is applied in the field of safe storage and can solve problems such as flying, human and environmental damage, and material dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

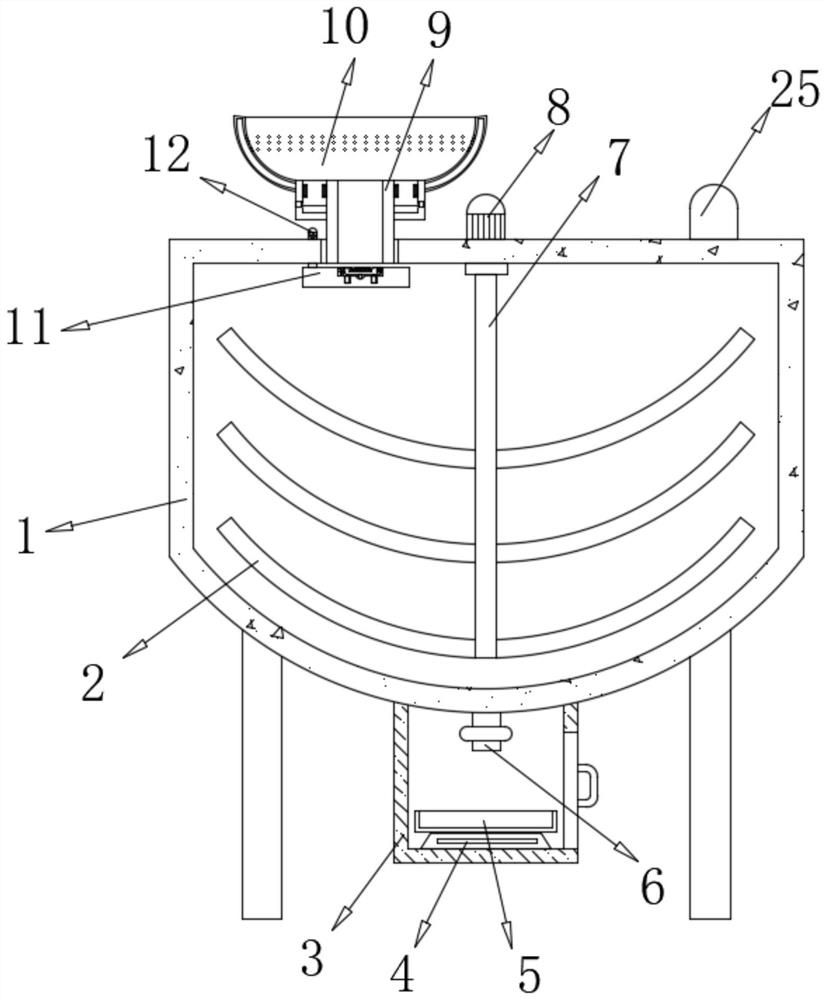

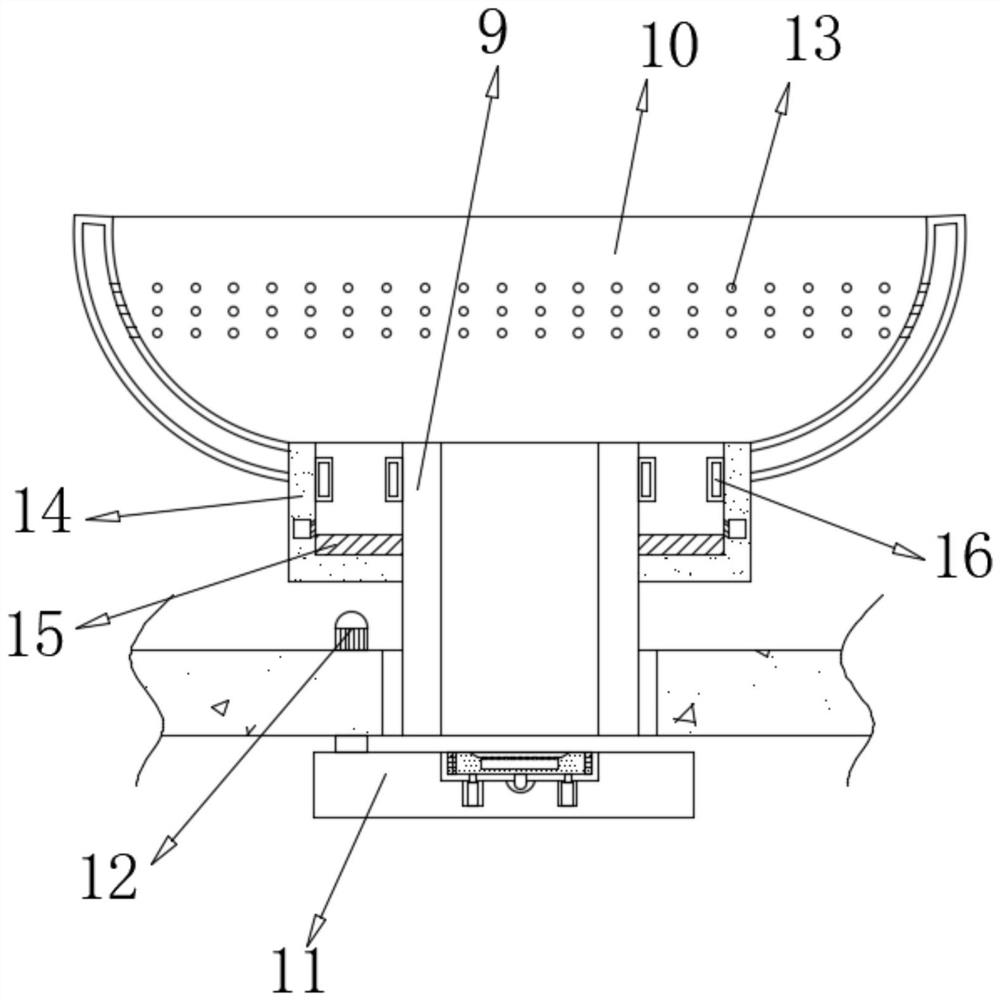

[0027] refer to Figure 1-4 , a safety storage device for antimony trioxide, comprising a storage barrel 1, a bottom outer wall of the storage barrel 1 is inserted with a feeding pipe 6, and a top outer wall of the storage barrel 1 is inserted with a feeding pipe 9, and the circumference of the feeding pipe 9 is The top of the outer wall is connected with a fixed groove 14 by fastening bolts, and the peripheral inner wall of the fixed groove 14 and the peripheral outer wall of the feeding pipe 9 are all connected with a sealed air bag 16 by fastening bolts, and the outer wall of the storage barrel 1 is connected by a fastening bolt. Air pump 25, the top of the peripheral outer wall is connected with an extension cover 10 by fastening bolts, and the peripheral inner wall of the extension cover 10 is provided with uniformly distributed water outlet holes 13, and the top outer wall of the storage barrel 1 is connected with a rotating motor 12 by fastening bolts, and The output sh...

Embodiment 2

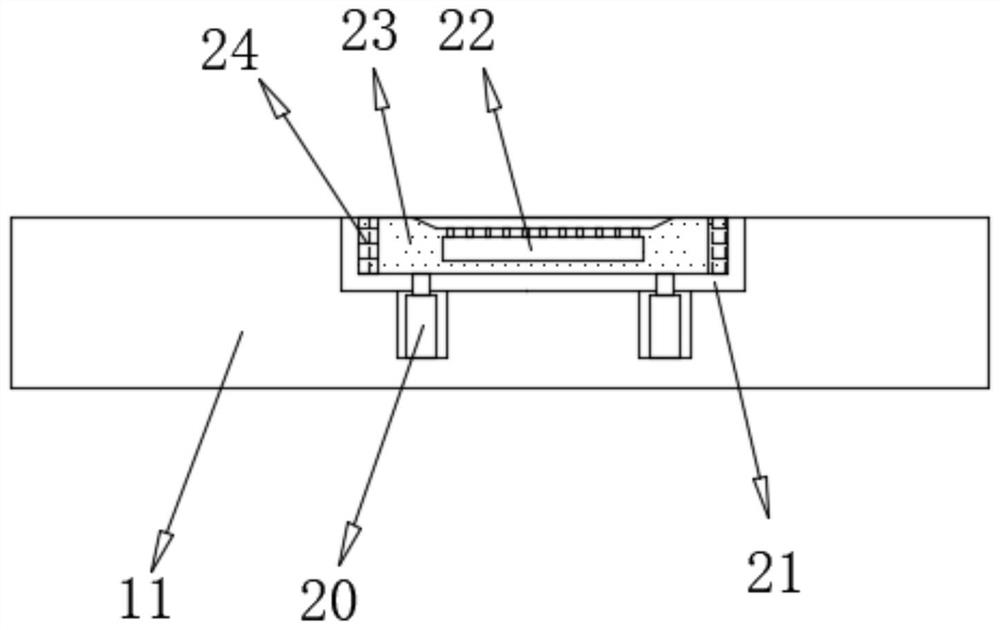

[0037] refer to Figure 5 , a safety storage device for antimony trioxide. Compared with Embodiment 1, the outer wall of one side of the sealed air bag 16 is connected with a sealing ring 18 through fastening bolts, and the side of the sealing ring 18 away from the sealed air bag 16 is opened There are evenly distributed grooves 19 .

[0038] Working principle: when the sealing airbag 16 is inflated, the sealing ring 18 will be attached to the inner or outer wall of the opening of the barrel. Since the sealing ring 18 is made of flexible material, the sealing ring 18 will expand with the expansion of the sealing airbag 16, and the groove 19 will The inner wall fits closely with the opening of the barrel to improve the sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com