Warp roller of textile machine

A warp roller and textile machine technology, applied in textile, loom, textile and paper making, etc., can solve the problems of cumbersome operation, difficult to make uniform size of warp roller surface, achieve uniform pay-off speed, uniform arrangement, avoid collapsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

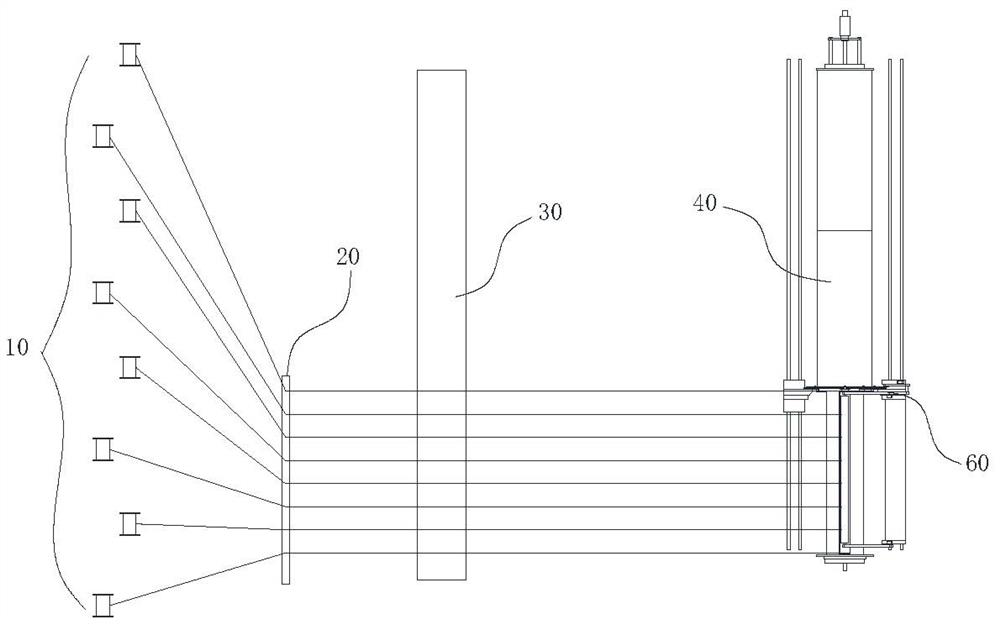

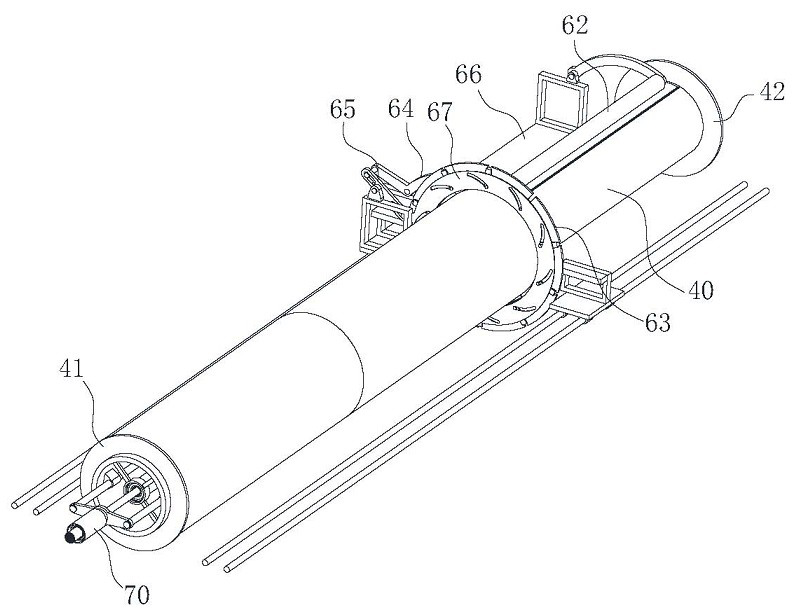

[0033] a textile machine, such as figure 1 As shown, it includes a warp roller winding mechanism, and the warp winding mechanism includes a warp roller, a guide plate 20, a pay-off roller 10 and a shaping roller 30, and the pay-off roller 10 is arranged on a pay-off rack in a plurality of arrays, The thread ends on each pay-off roller 10 are drawn in the same direction, and each thread end passes through the threading holes 21 arranged in an array on the guide plate 20 respectively, and is finally wound on the warp roller; the shaping roller 30 tensions the thread between the warp roller and the guide plate 20 and arranges the threads at equal intervals; the warp roller includes an outer roller 40 and an inner roller 50 that are coaxially rotatably connected, and the inner roller 50 is located at Inside the outer roller 40, the roller surface of the outer roller 40 is provided with a bar hole 401 penetrating the wall of the outer roller 40 along the direction of the generatrix...

Embodiment 2

[0044] A kind of textile machine warp thread winding method described in embodiment 1, comprises the steps:

[0045] Step 1: Set the warp roller;

[0046] Step 2: Pulling the wires, laying out the array of pay-off rollers 10 on the pay-off frame, moving the end of the thread on each pay-off roller 10 out and passing through the threading holes 21 set on the guide plate 20;

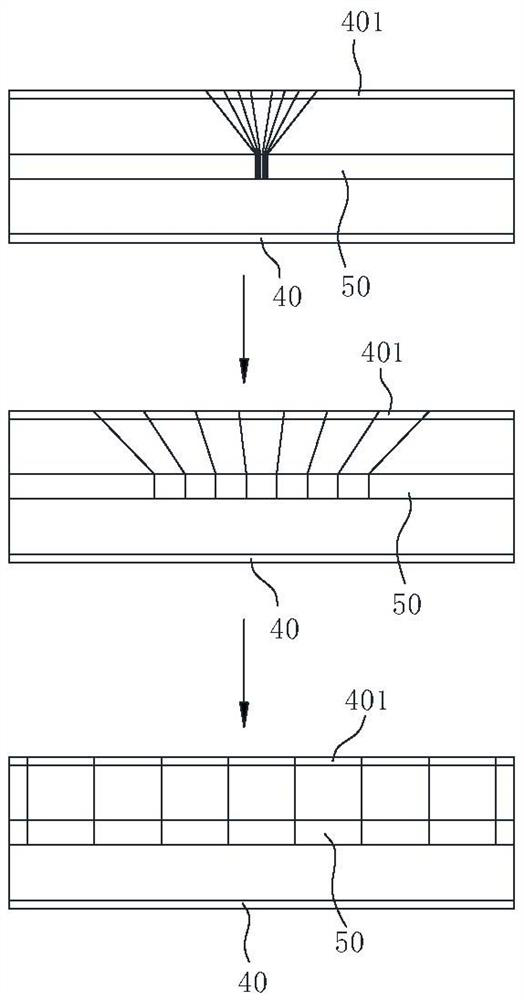

[0047] Step 3: Bundle the wire ends into a bundle and fix it at the center position of the first inner roller 50, and spread the wire between the inner roller 50 and the guide plate 20 on the shaping roller 30;

[0048] Step 4: Rotate the first inner roller 50 and keep the outer roller 40 still, so that each thread gradually spreads from the center of the first inner roller 50 to both ends;

[0049] Step 5: Start the outer roller 40 when the silk thread covers the entire roller surface of the first inner roller 50, and make the outer roller 40 and the first inner roller 50 rotate synchronously, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com