Anti-seismic and anti-falling beam structure

An anti-falling beam and anti-seismic seat technology, applied in the field of anti-falling beams, can solve the problems of single anti-falling beam anti-seismic structure, reducing the service life of bridges, complicated operation of anti-falling beams, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

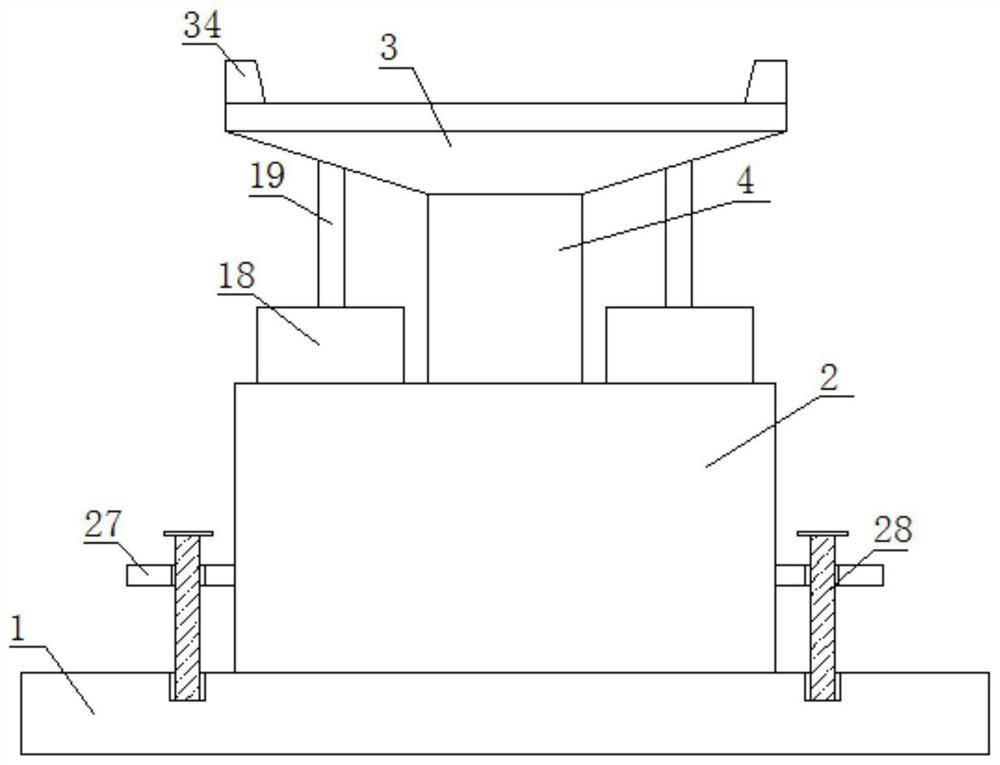

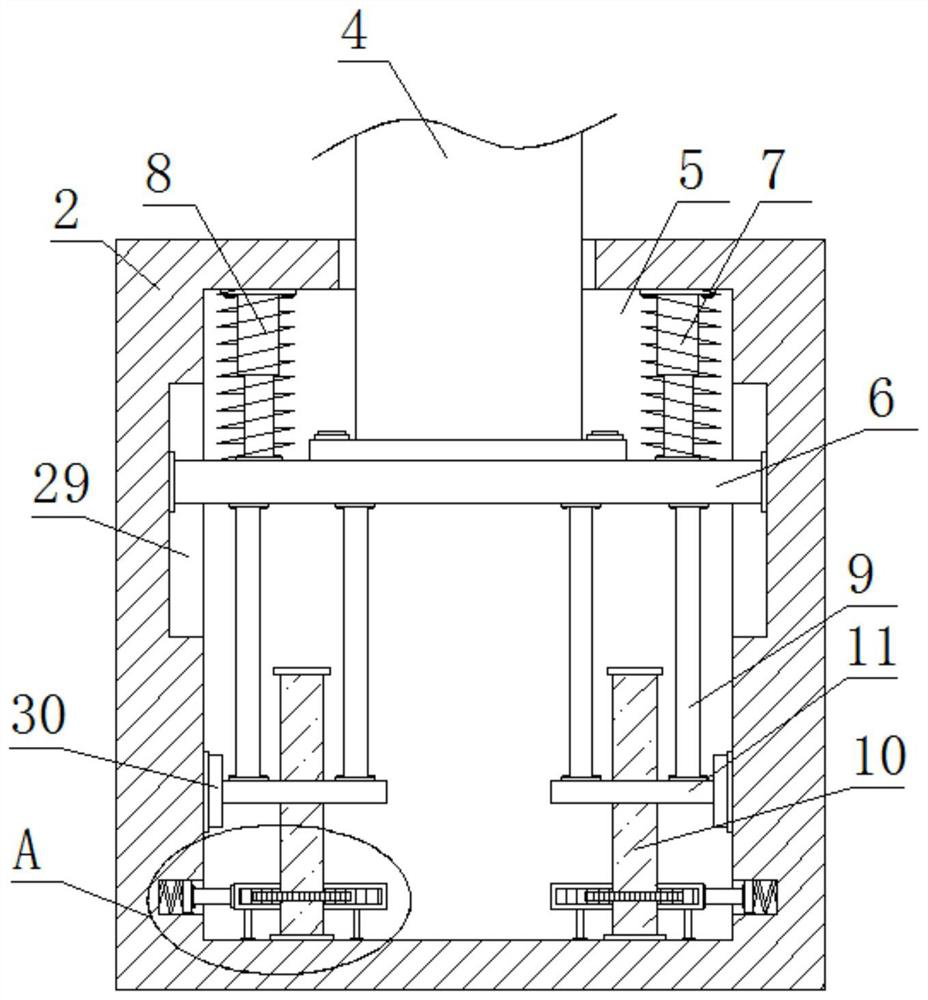

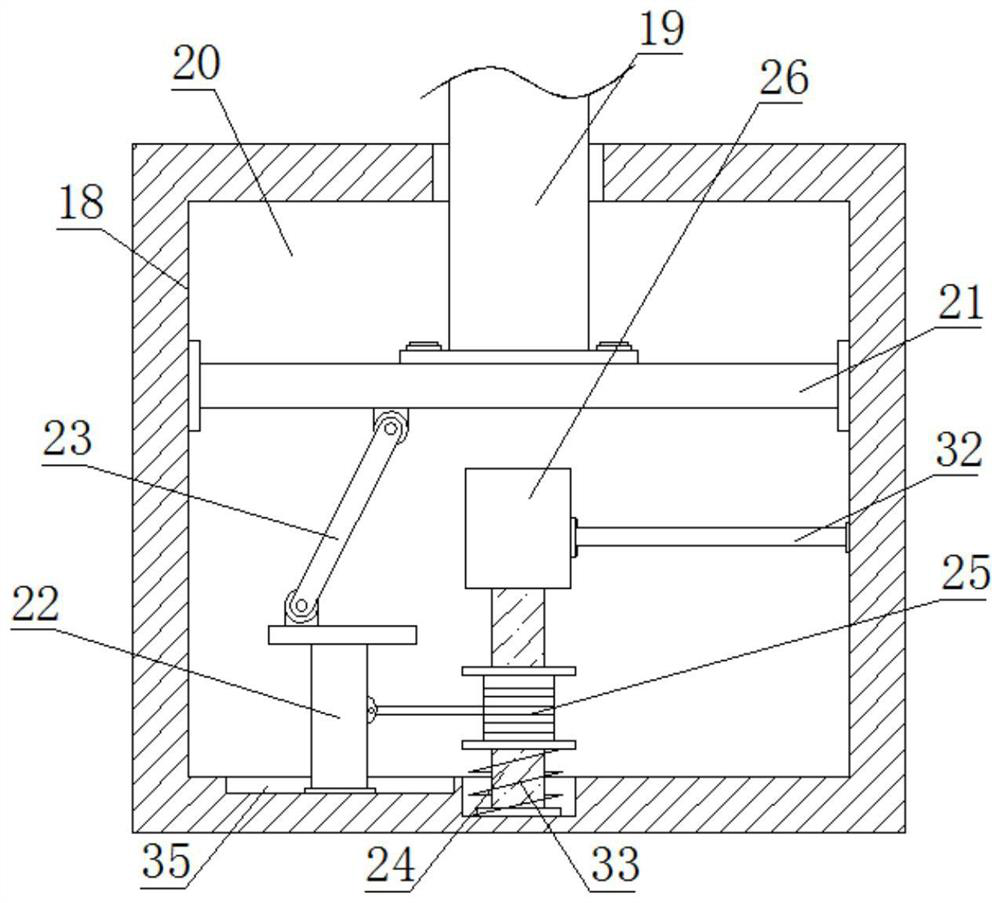

[0029] Such as Figure 1-5An anti-seismic anti-fall beam structure shown includes a bridge pier 1 and an anti-fall beam main body 3, the top of the bridge abutment 1 is movable with an anti-seismic seat 2, and the bottom of the anti-fall beam main body 3 is fixedly connected with an anti-seismic The fixed column 4 on the seat 2 is provided with an installation chamber 5 on the anti-seismic seat 2, and a moving plate 6 is slidably connected in the installation chamber 5, and the bottom end of the fixed column 4 extends into the installation chamber 5 and is connected to the The bottom is fixedly connected, the top inner wall of the installation chamber 5 is symmetrically fixedly connected with two telescopic rods 7, the bottom ends of the two telescopic rods 7 are fixedly connected with the top of the moving plate 6, and the two telescopic rods 7 are sleeved The first spring 8, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com