Concrete maintenance device for hydraulic engineering construction

A technology for water conservancy projects and concrete is applied in the field of concrete curing devices for water conservancy project construction, which can solve the problems of troublesome work of concrete curing and mulching, affecting the construction period, poor surface flatness of the curing membrane, etc., so as to ensure the quality of continuous maintenance and avoid prolonging the construction period. , The effect of convenient lamination work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

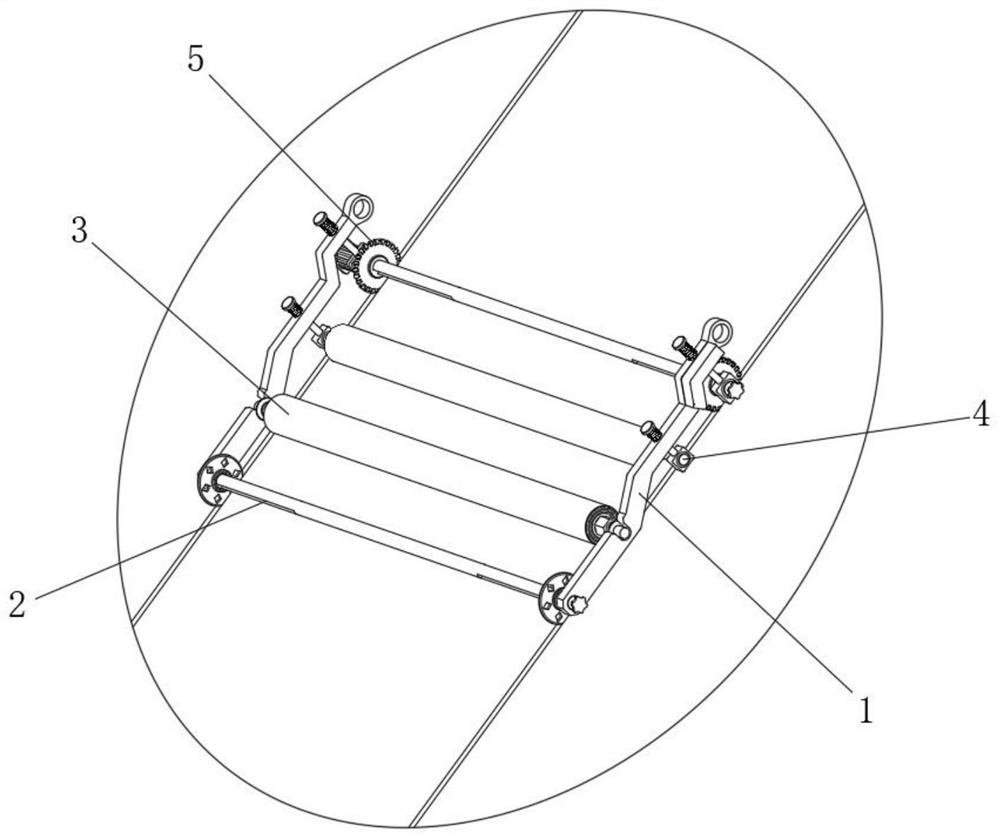

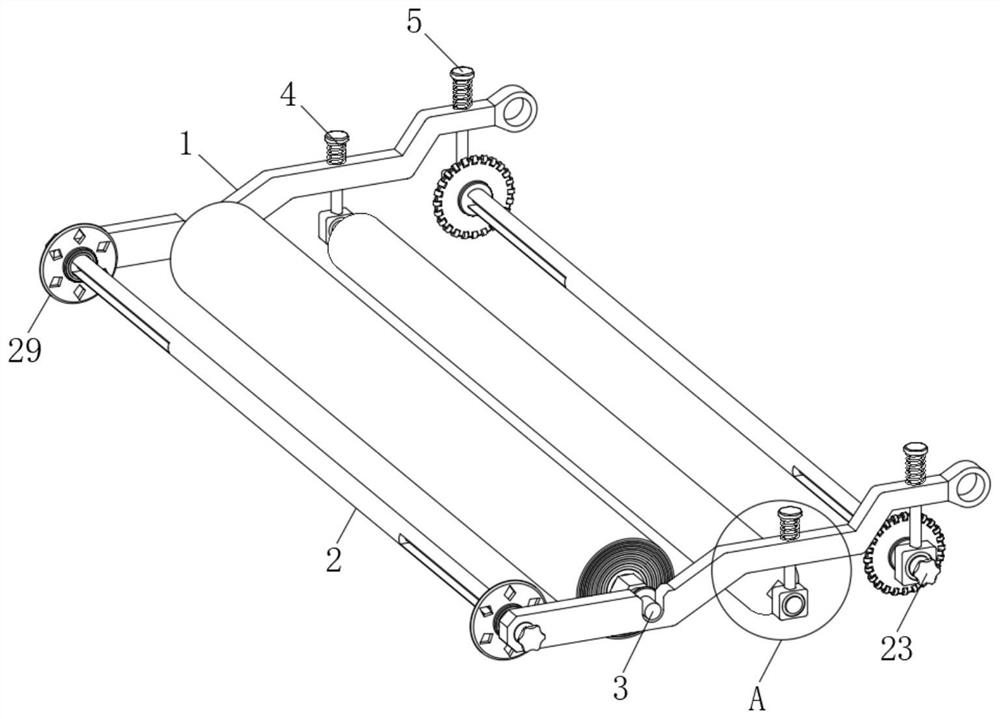

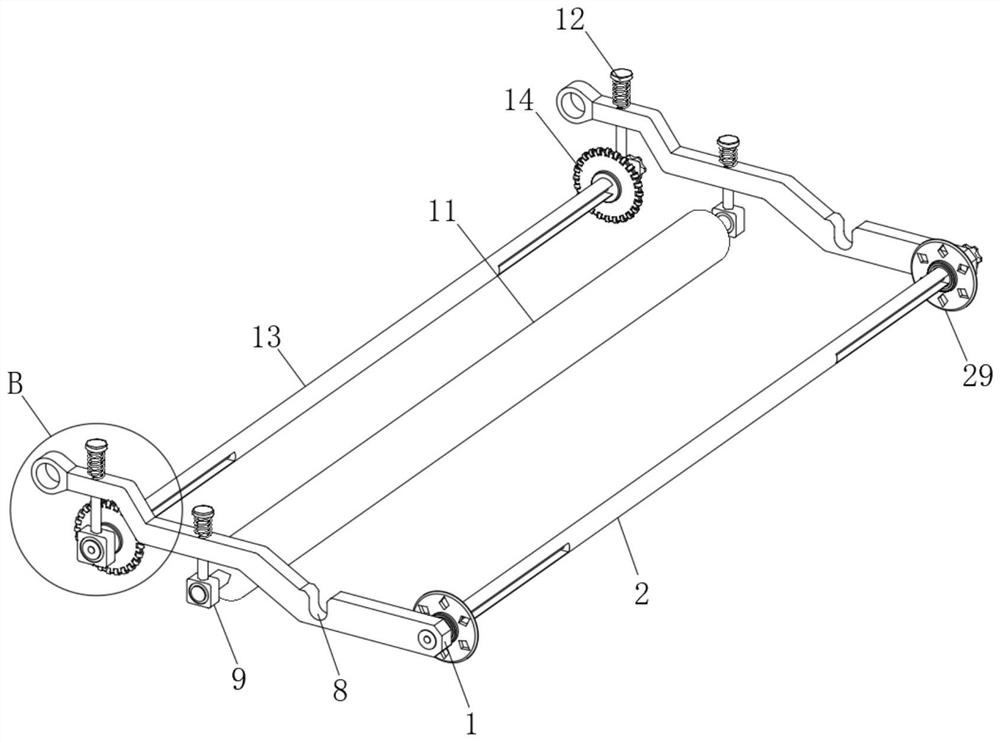

[0031] see Figure 2-10 , the present invention provides a technical solution: a maintenance device for concrete in hydraulic engineering construction, including two load-bearing side plates 1 for installation and fixing, and the load-bearing side plates 1 have a polygonal plate structure but are not limited thereto;

[0032] Between the two load-bearing side plates 1 is provided a connecting main shaft 2 installed through bearing rotation, and between the two load-bearing side plates 1 is provided a film roll fixing mechanism 3 that can be easily disassembled and assembled in real time, and the film roll The side of the fixing mechanism 3 away from the main shaft 2 is provided with a rolling mechanism 4 connected to the bearing side plates 1 on both sides for real-time paving and rolling of the maintenance film to remove air, and the rolling mechanism 4 is far away from the film roll fixing mechanism 3. One side is provided with a guide plugging mechanism 5 for cooperating wi...

Embodiment 2

[0044] see Figure 11 , the present invention provides an optimized technical solution of Embodiment 1: any end of the plug-pressing spindle 13 is connected with a drive motor 33 fixed on the mounting base, preferably the model 57HB76-401A, and during real-time use, the A mobile power supply is installed on the side bearing side plate 1 to ensure power supply and drive. Specifically, the mobile power supply can use a rechargeable lithium battery. Further, the side of the load side plate 1 away from the drive motor is fixed with a counterweight 34, and the drive motor 33 It can be used to drive and rotate the plugging spindle 13 to provide its self-rotating plugging capacity, effectively improve the real-time plugging capacity of its curing film, and ensure high-efficiency plugging. The setting of the counterweight 34 is to balance the main body of the device The weight on both sides is to ensure that it moves down the film in a stable and deflected straight line on the slope. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com