Novel chute for highway engineering

A rapid trough and engineering technology, applied in the rapid trough field, can solve the problems of easy blockage, difficult maintenance and cleaning, and difficult adjustment of the length of the rapid trough, so as to achieve the effect of slowing down the water speed and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

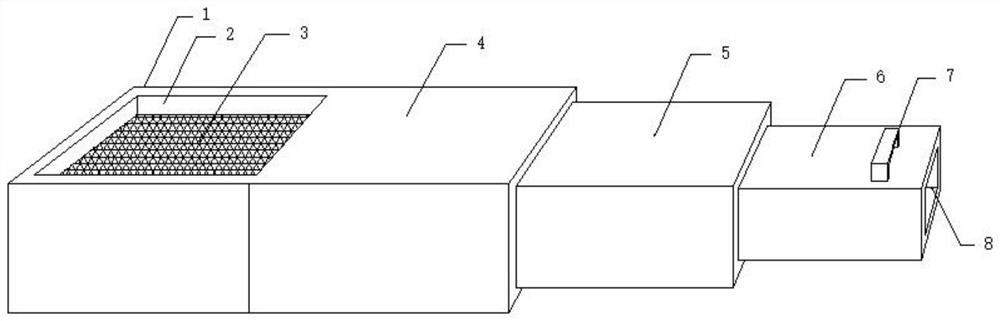

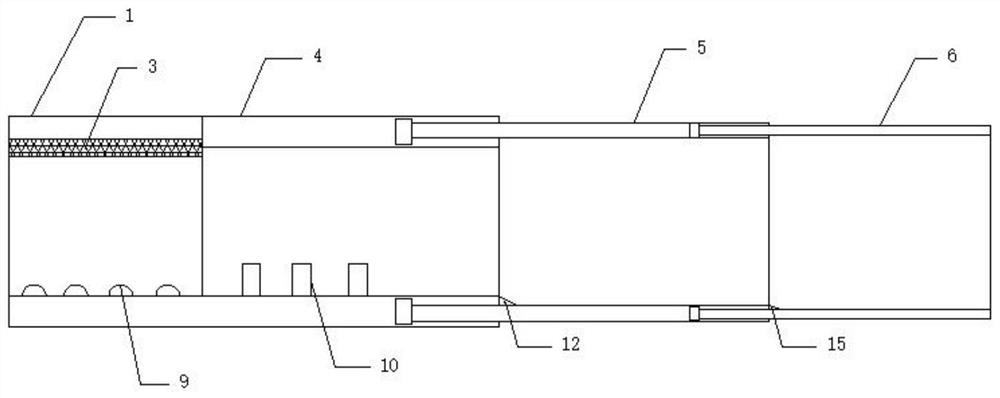

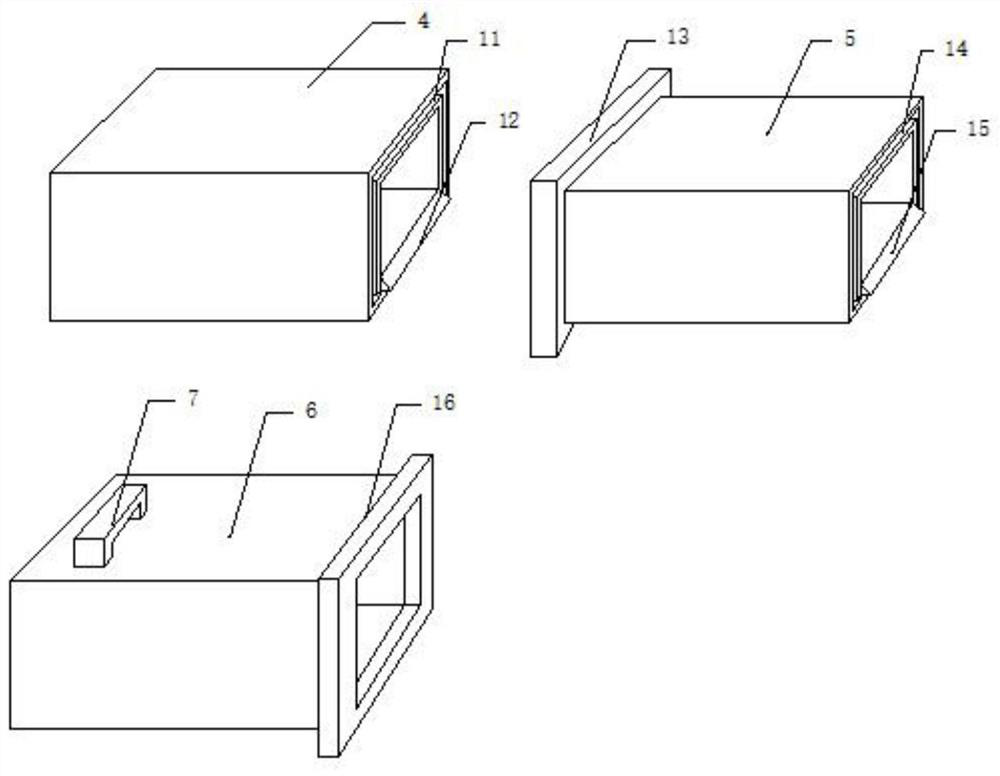

[0020] Such as Figure 1-4 Shown, the present invention provides a kind of novel rush chute for highway engineering, comprises first rush trough 1, second rush trough 4, the 3rd rush trough 5 and the 4th rush trough 6, the top of the first rush trough 1 is provided with advance One end of the water inlet 2 and the water inlet 2 is provided with a filter screen 3, one end of the first rapid trough 1 is fixedly connected with the second rapid trough 4, and one end of the second rapid trough 4 is provided with the first movable trough 1 and the third rapid trough 5 One end is provided with a first projection 13, the first projection 13 is located inside the first movable groove 11 and is movably connected with the first movable groove 11, and the third rapid flow groove 5 moves with the second rapid flow groove 4 through the first projection 13 connected, the other end of the third rapid chute 5 is provided with a second movable groove 14, and one end of the fourth rapid chute 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com