Rivet assembling tool for cylindrical roller bearing

A cylindrical roller bearing and rivet technology, applied in the field of assembly tooling, can solve the problems of low efficiency, rivet riveting, waste of cost, etc., and achieve the effects of improving product quality, avoiding rivet chiseling, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

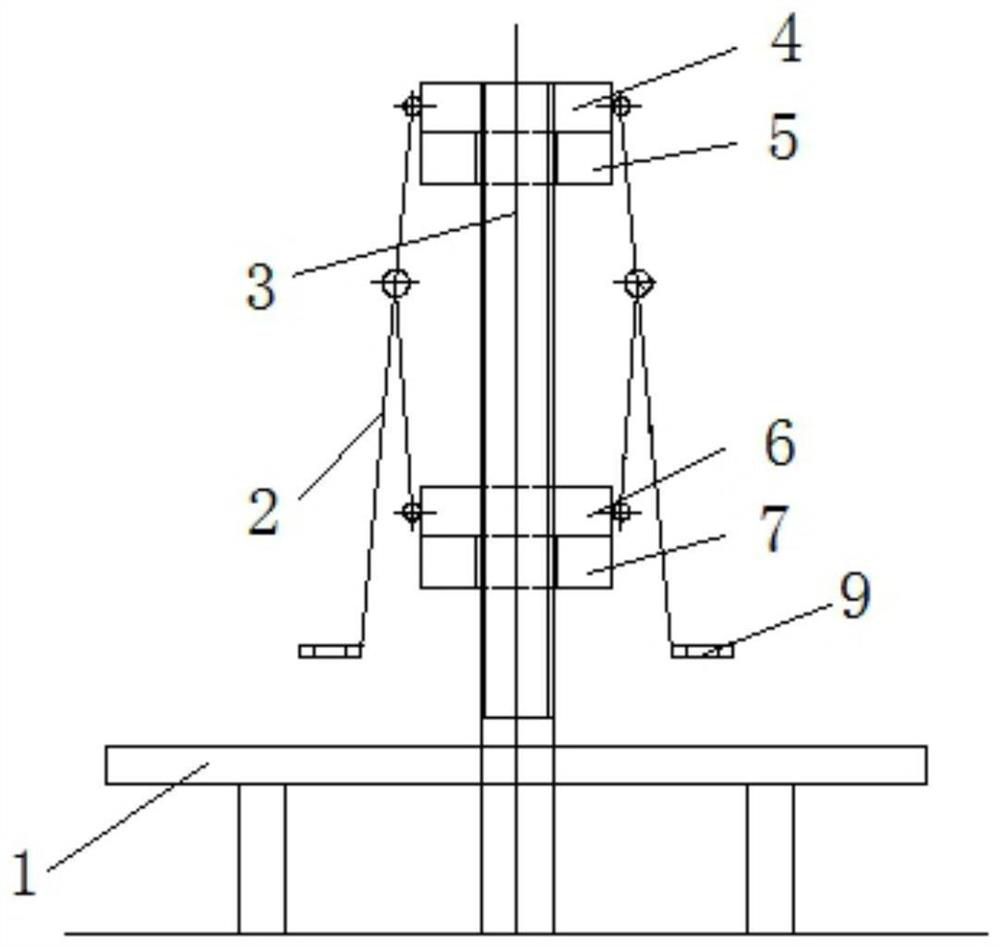

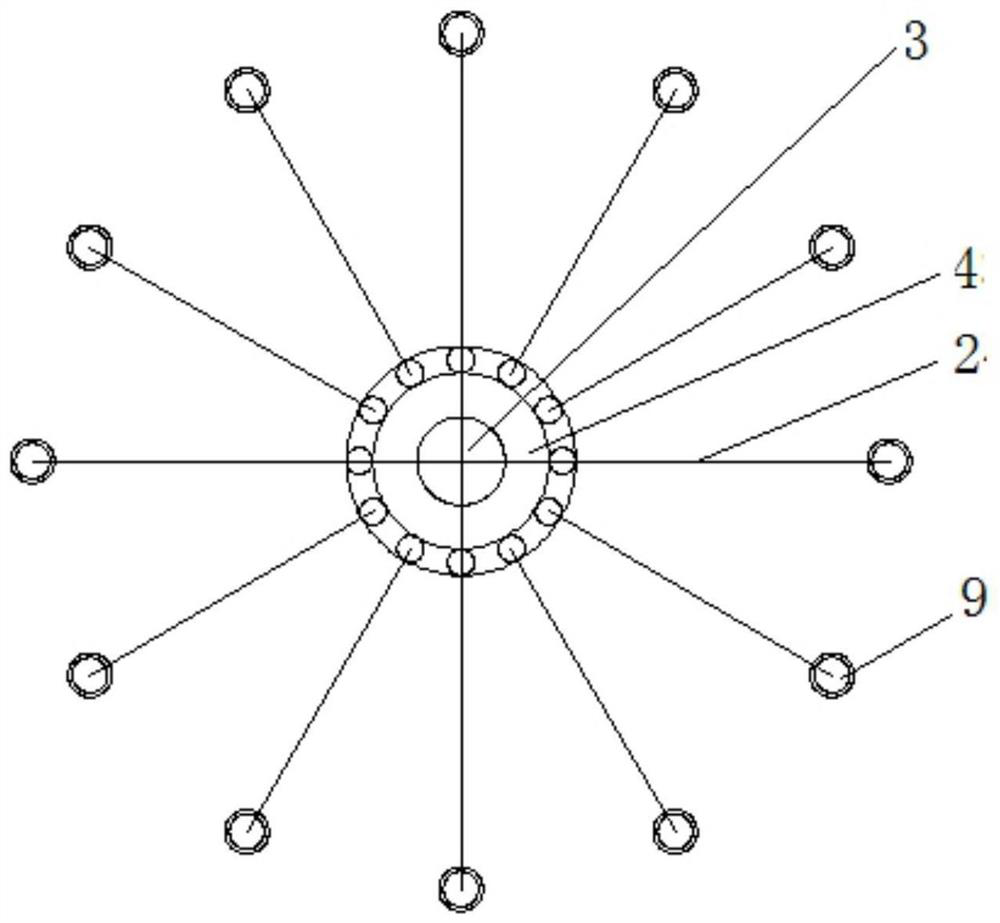

[0014] Embodiment is illustrated below in conjunction with accompanying drawing:

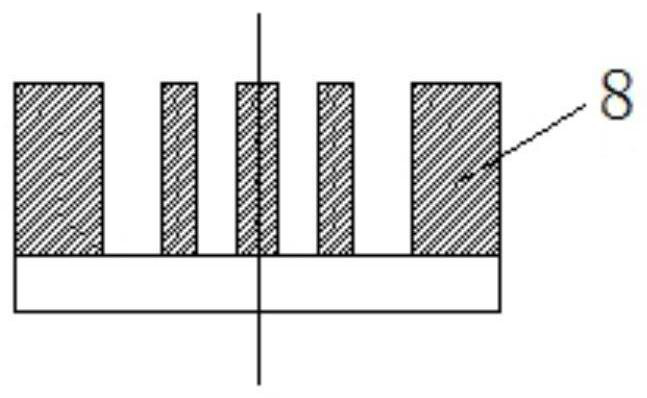

[0015] The present invention includes: lifting platform 1, connecting rod 2, column 3, 1# positioning block 4, 3# positioning block 5, 2# positioning block 6, 4# positioning block 7, angle bisecting positioning block 8, ring 9; The lower part of the platform 1 is equipped with a hydraulic cylinder, the column 3 is placed in the center of the platform 1, and its upper half is processed with threads, which correspond to the threads in the center holes of the 3# positioning block 5 and 4# positioning block 7, and the 1# positioning block 4. The center hole of 2# positioning block 6 is not threaded, and it is respectively connected with the upper and lower ends of the connecting rod 2, and the bottom end of the connecting rod 2 is provided with a ring 9.

[0016] When the present invention manufactures and processes the bearing, the angle bisecting positioning block 8 is placed on the column 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com