High-precision inner conical surface taper rapid detection tool

A technology for detecting tooling and inner tapered surfaces, applied in angle/taper measurement, measuring devices, mechanical measuring devices, etc., can solve problems such as insignificant difference in light transmission of gauges, waste of manpower and equipment resources, and affect production efficiency, etc., to achieve quality High stability, eliminate missed detection and discharge, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

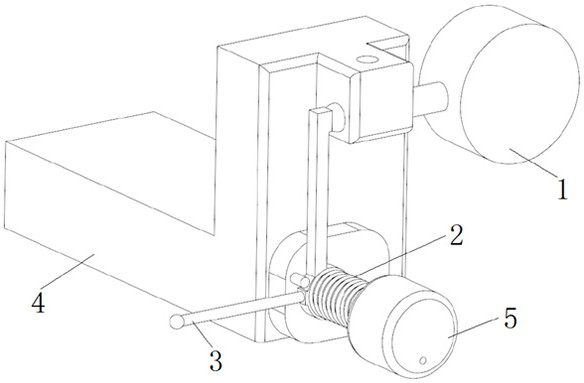

[0019] The invention is a tool for quickly detecting the taper of a high-precision conical surface, such as figure 1 As shown, its components mainly include dial indicator 1, spring 2, detection arm 3, support 4, support bolt 5, of which:

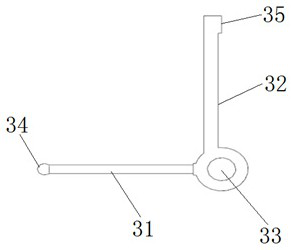

[0020] The structure of detection arm 3 is as figure 2 As shown, it includes: a detection rod 31, a push rod 32, a bolt hole 33, a probe 34 and a probe contact end 35, wherein: the detection rod 31 and the push rod 32 are equal in length and 90 degrees to each other, and the detection rod 31 It is an oblong rod, and a probe 34 is set at the free end of the detection rod 31. The diameter of the probe 34 is greater than the diameter of the detection rod; The end 35 is used to contact the measuring head of the dial indicator. In order to keep the contact between the two more stable, the contact surface between the measuring head contact end 35 and the measuring head is designed as an arc-shaped groove. The support bolts 5 pass through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com